107

105

106

10

- 54 -

FUEL SYSTEM

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

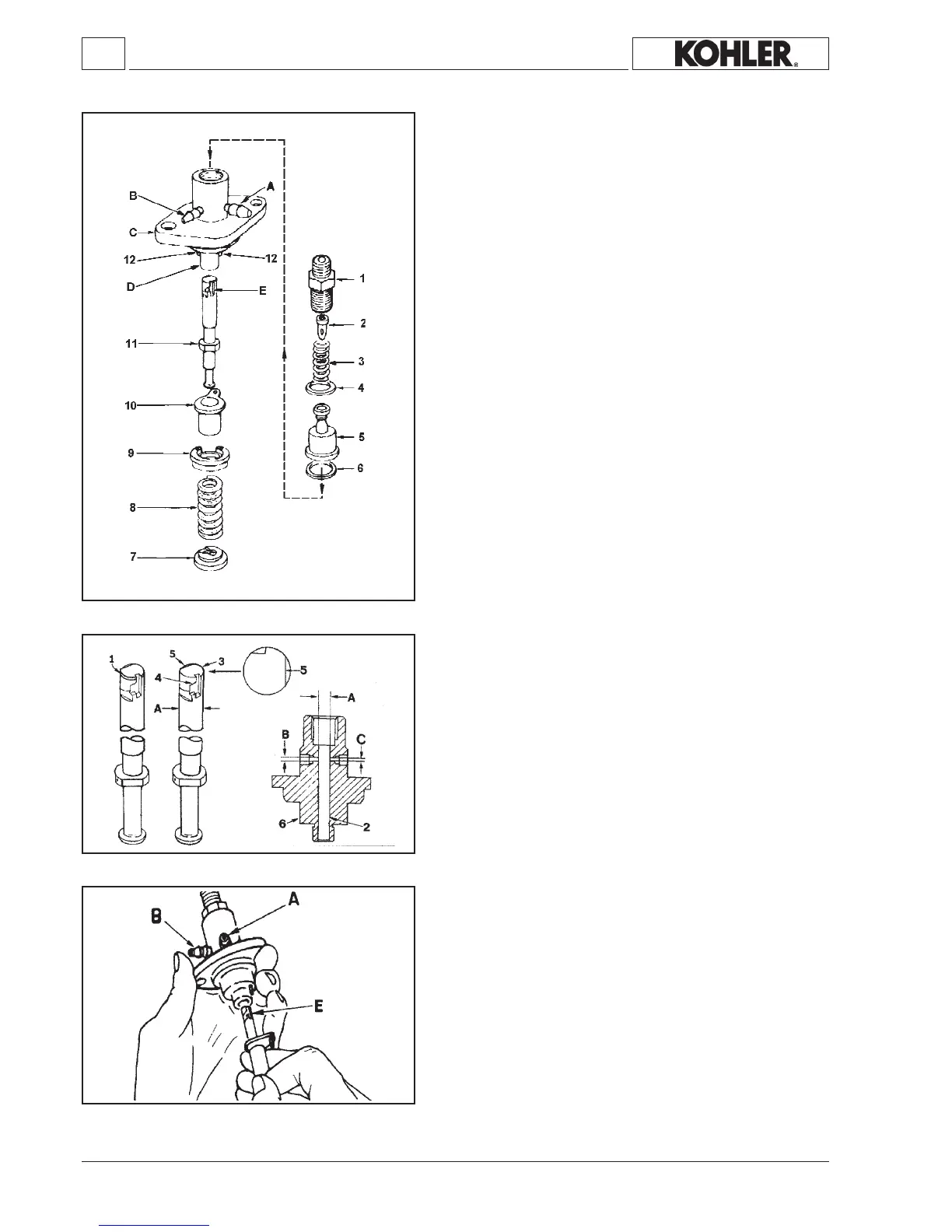

Injection pump components and disassembly

1 Deliveryunion

2Filler

3 Spring

4Gasket

5Valve

6Gasket

7Springretainer

8Spring

9 Springplate

10Rack

11Plunger

12Pin

A=Fueloutletunion

B =Fuelintakeunion

C=Fastening

D=Barrel

E=RHhelix

Demountincompliancewiththenumericorder.

Plate9is heldrmbypins 12.Leverupbyinserting a toolbetween

theplateandthebodyofthepump.

Thevolumeshiftedbydeliveryvalve 5 is 15

mm

3

inthepumpofKD

315-350and25mm³inthepumpofKD225is21mm

3

inthepumpof

KD400/440

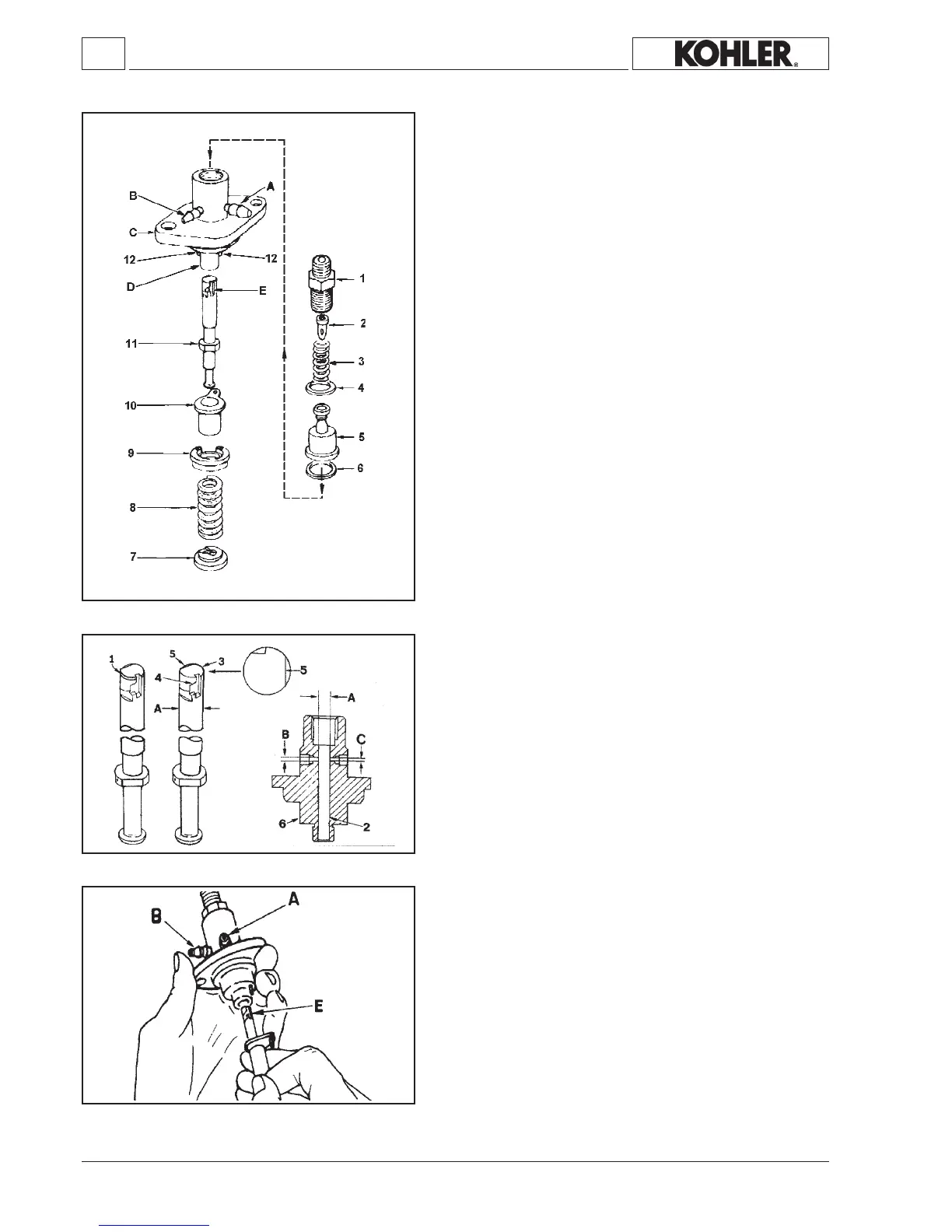

Injection pump, body, plunger and delivery valve

Components: Dimensionsmm:

1 Deliveryvalve A=5.50(nominaldiam.)225-315-350

2 Barrel A=7,00(nominaldiam.)400-440

3Plunger A=6,00(nominaldiam.)315-350EPA

4 Righthelix B=2.00/2.03

5Delaynotch C=1.50/1.53

6Pumpbody

7 Collar

Note: The injection pump installed in engines for small vehicles,

soundproof generating sets, EPA and KD 400-440 engines,

arecharacterisedbytheinclusionofacollar1whichcontribu-

testonoise-reduction.

Injection pump retting

The plunger is tted with helix E facing towards the outlet union A;

ifitismistakenlyttedwiththehelixfacingtheintakecouplingBthe

injectionpumpnolongeroperates(thereisnodangerofengineru-

naway);completerettingfollowingg.107.

Loading...

Loading...