18

19

20

8

- 26 -

DISASSEMBLY/REASSEMBLY

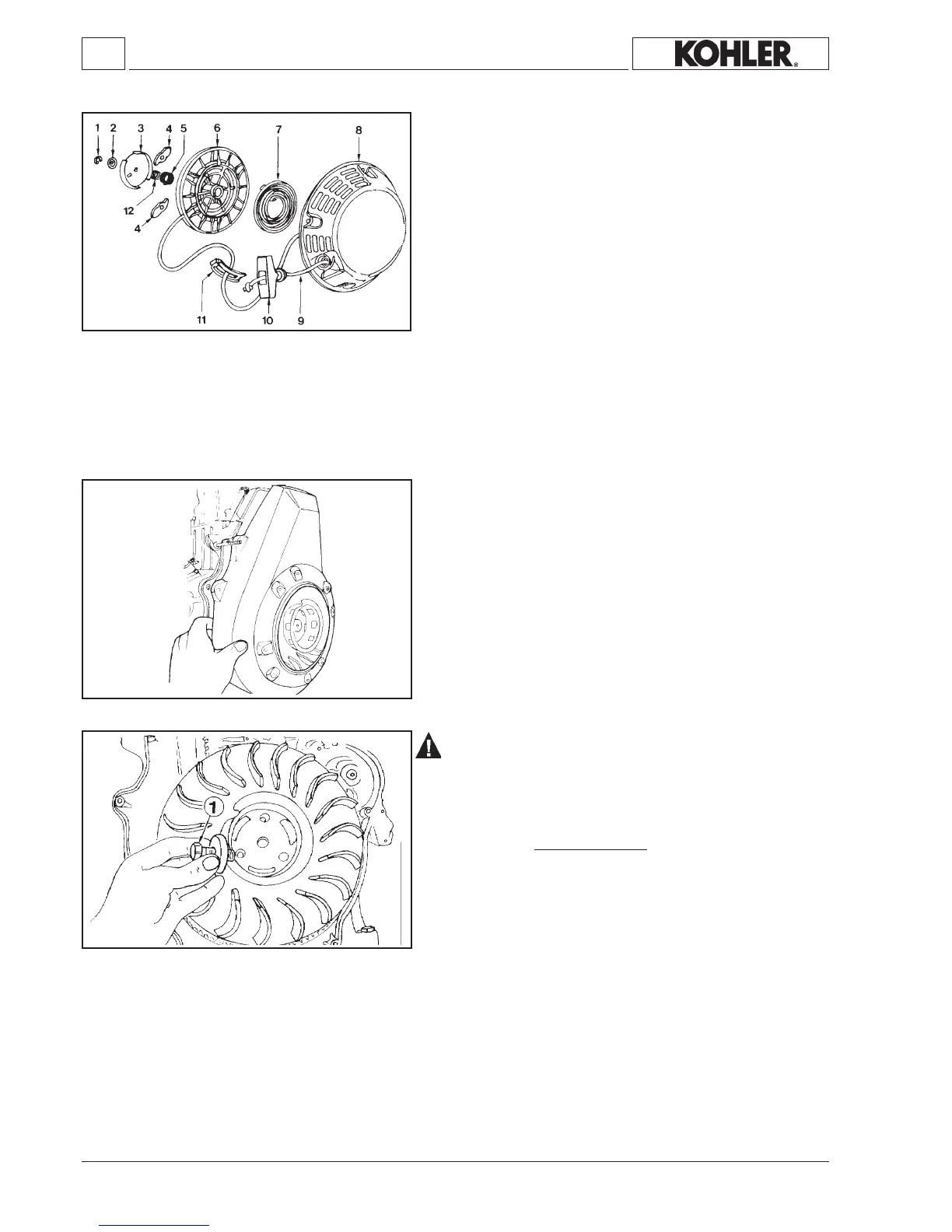

Re-coil starting

Operation:

Whenpullinghandle10,thankstotheactionoffrictionspring12,te-

eth 4 protrudefrom cap 3.After startingthese teeth goback to the

initial position because the cap rotates. Rope 9 is re-wound around

pulley6bymeansofspring7.

Components:

1 Retainer 7Spring

2 Washer 8Guard

3Cap 9 Rope

4Flyweights 10Handle

5 Spring 11 Ropeguide

6Pulley 12 Spring

Note:there are two kinds ofguards 8, one for engineswith an rpm

above 2000 and one with fewer cooling channels for engines

withalowerrpm

Onreassembly,tightenthescrewsto10Nm.

Shroud

Theshroudand the metalsheetingoutsidethecylinderaremadeof

specialmaterial(ANTIPHON)whichabsorbsnoise,thusreducingto-

talenginesoundpressurelevels.

Whenrettingtightenshroudscrewsto10Nm.

Duringthedemountingphases,payparticularattentiontopre-

vent the ywheel from dropping as this could seriously injure

theoperator.

Wearprotectivegoggleswhenremovingtheywheelring.

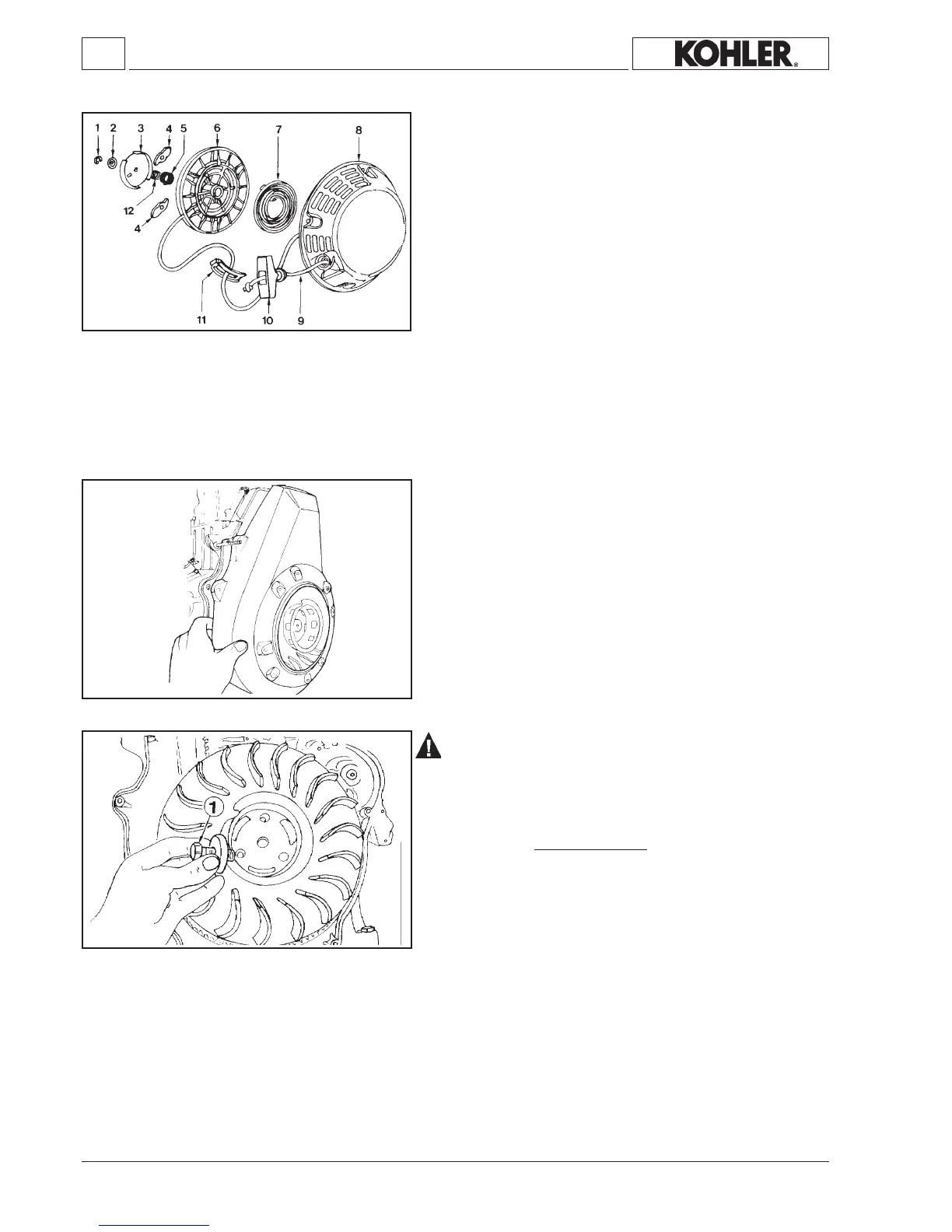

Flywheel

Unscrewbolt1inaclockwisedirection.

Removetheywheelwithapuller.

Makesurethatthe tapered surface thatcouplestothedriveshaftis

notdamaged.

To remove the starter rim, it is advisable to cut it into several parts

withahacksawandtothenuseachisel.Toreplace, slowly heat for

15-20minutestoatemperatureof300°Cmax.

Fit the rim into the ywheel housing. make sure that it rests evenly

againstthesupportofthehousingitself.

Allowittoslowlycool.

Whenrettingtightenbolt1to150Nm.

Seepages34and35forinjectiontimingreferencemarks.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Loading...

Loading...