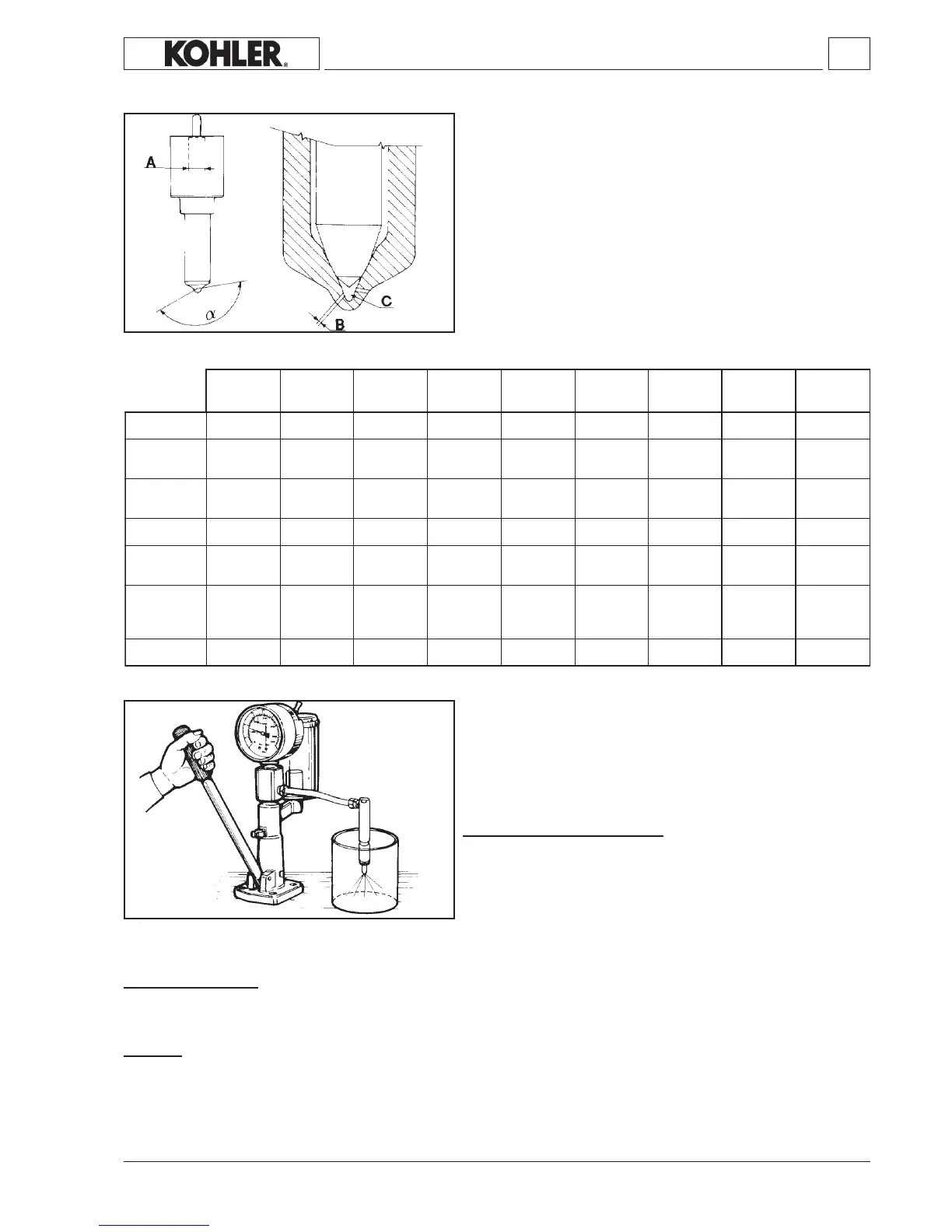

A

5,4 5,4 5,4 5,4 5,4 5,4 5,4 5,4 5,4

B

71,0x4 02,0x4 141,0x5 22,0x4 141,0x5 951,0x5 051,0x5 661,0x5 561,0x5

5,0 6,0 8,0 6,0 8,0 5,0 8,0 5,0 8,0

aa

a

aa

°061 °061 °551 °061 °541 °061 °061 °061 °551

÷01,0

51,0

÷01,0

51,0

÷571,0

522,0

÷521,0

571,0

÷571,0

522,0

÷573,0

524,0

÷573,0

524,0

÷573,0

524,0

÷573,0

524,0

C

³mm63,0 ³mm63,0 ³mm0 ³mm63,0 ³mm0 ³mm91,0 ³mm0 ³mm91,0 ³mm0

4±412 4±412 6±042 4±412 6±042 4±002 4±952 4±002 6±042

- 59 -

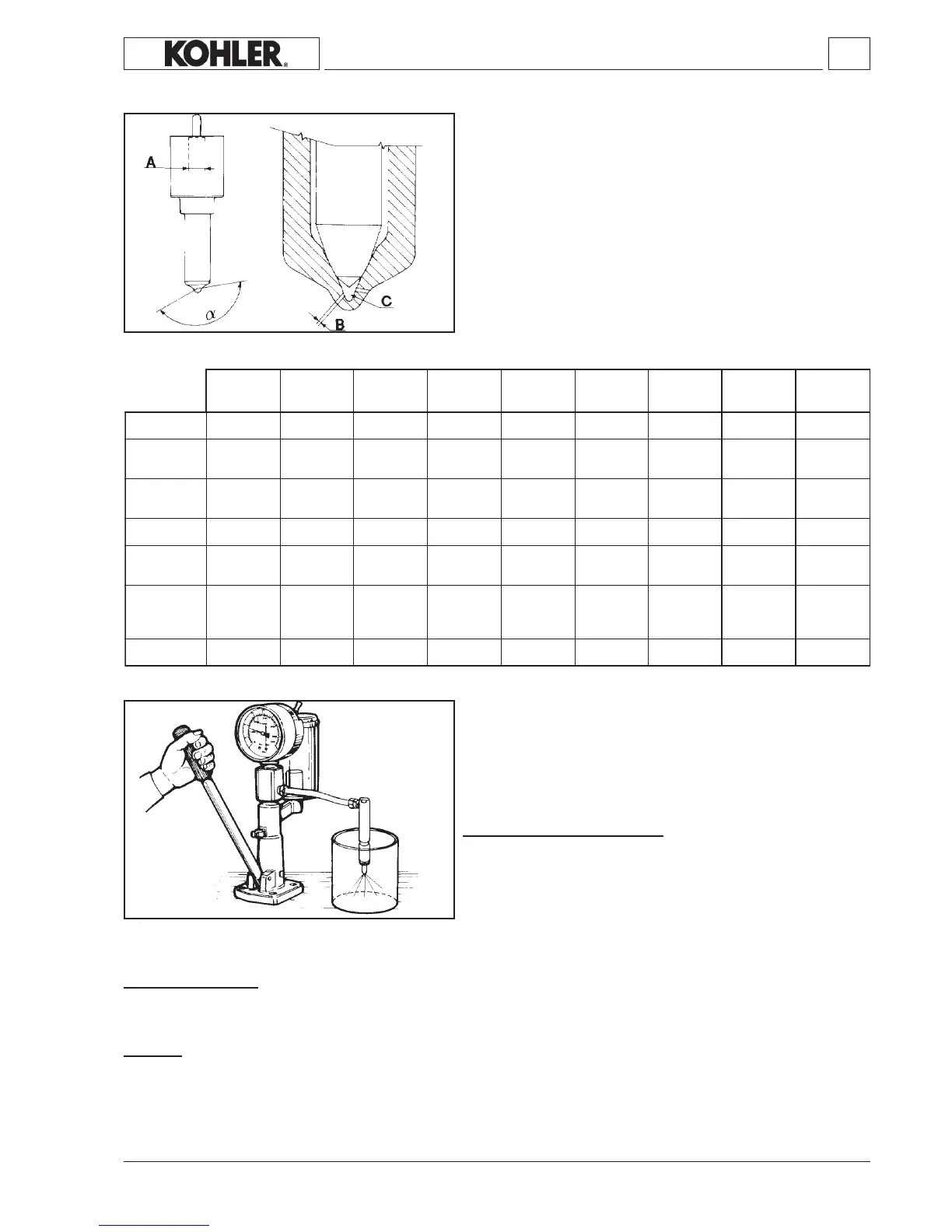

FUEL SYSTEM

Leakage time (waste)

Pressuremustdropfrom150to100barsinaspanofnotlessthan8secondsandnotmorethan30.

Seatseal

Nozzletipwet.

Pressuremustbekept20barsbelowtheopeningpressurefor10seconds.

Afterthistime, dampness onthenozzletipisacceptable,andmaybeidentied bytouchingwithadrynger.Onlya dropof

dampnessisacceptableandnotalargethickpatchwhichwouldindicatealeak.

Injector calibration

Connect the injector to a hand pump and adjust if necessary,

modifyingthethicknessabovethespring.

When the spring is replaced, calibration must be carried out at a

pressure higher than 10 bars to counterbalance adjustments while

running.

Spraying and opening pressure

With the pressure gauge closed, press hard on the hand pump at

least10times.

Open the pressure gauge and press down on the pump once every

second,whilekeepingacheckonthesprayingprocessandpressure.

The opening pressure must lie between the two values given in the

table.Jetsmustbeuniformandwelldistributed.

*Thesevaluesapplytonewinjectorandallowforlooseningofupto10%afterbreaking-inperiod

Nozzles

Theset-up betweentheneedleandtheguidemustleavetheneedle

freetofallandmerelyasaresultofitsownweight,whenlifted7mm

fromitsseatandrotatedindifferentdirections,withthenozzlekeptat

a45°angle.

Rotationoftheneedlemustbecompletelysmoothanduninhibitedby

obstaclesandmalformations.

Moreover,onbeingsqueezedagainstitsseat,itmustfallfreely,when

thenozzleisinverted.

Thetestmustbecarriedoutafterrinsingboththeneedleandnozzle

with trichloroethane and wetting with ltered SHELL CALIBRATION

FLUID“C”oil.

n°andØofholes

holelenght

pinheight

sumpvolume

pressure(bar)*

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Loading...

Loading...