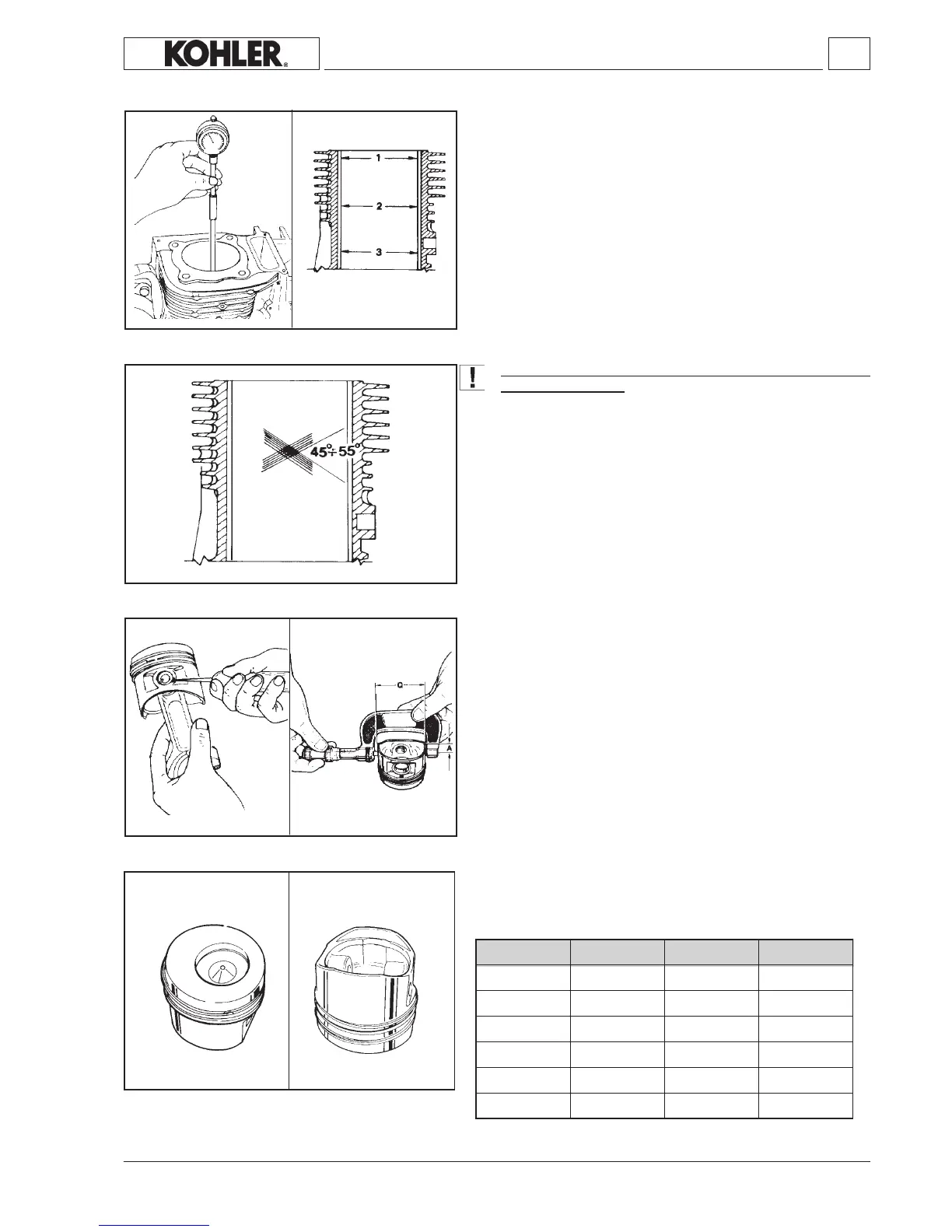

510,96÷00.96 079,86÷559,86 60.0÷30.0

51.87÷00.87 079.77÷559.77 60.0÷30.0

510.28÷00.28 079.18÷559.18 60.0÷30.0

510,28÷00,28 079,18÷559,18 60.0÷30.0

510,28÷00,28 049,18÷529,18 90.0÷60.0

510,68÷00,68 079,58÷559,58 60.0÷30.0

225

315

350 - 350EPA

400

400EPA

440 - 440EPA

ClearanceØ PistonØ Cilinders

- 31 -

DISASSEMBLY/REASSEMBLY

Cylinder

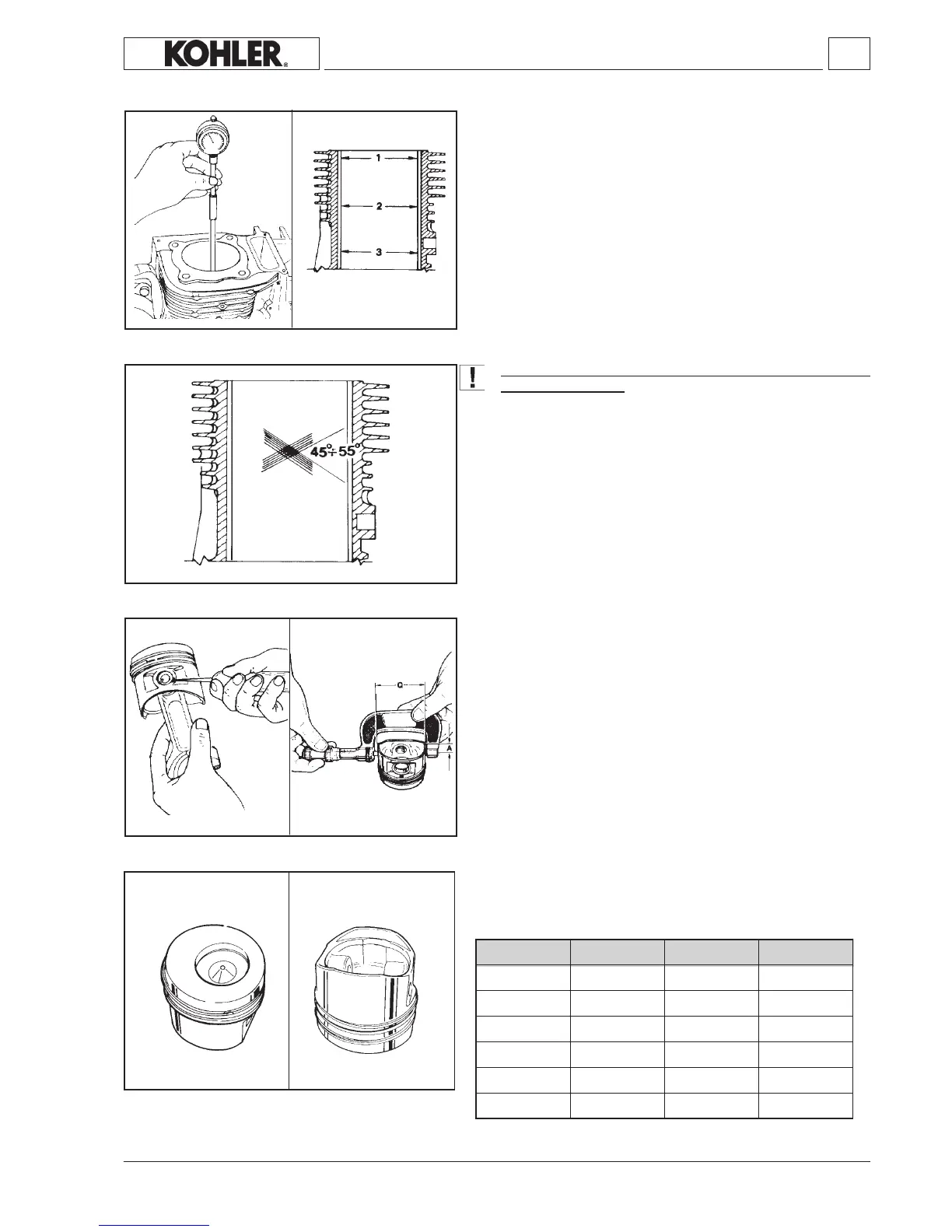

Setaboregaugetozerowithacalibratedring.

Checkdiameterat1, 2and3;repeattheoperationatthesamepoints

afterturningtheboregauge90°.

Ifwearexceedsthemax.givenvalueby0.05,borethecylinderandt

oversizepistonandrings.

Seeg.40and41forcylinderdiametervalues.

Do not manually hone the cylinder bore surfaces with emery

clothorothermeans.

Cylinder roughness

Thecross-hatchpatternshouldbeatanangleof45°-55°;linesshould

beuniformandclearinbothdirections.

Averageroughnessmustrangebetween0.5mm1µm.

Thecylindersurfacewhichcomesintocontactwithpistonringsshould

bemachinedwiththeplateaumethod.

Piston

Being of low expansion type, the piston allows small clearances

betweenpistonandcylinderand,thus,oilconsumptionisreduced.

Removecirclipsandpistonpin.

Removepistonringsandcleangrooves.

MeasurediameterQattheAdistance from the skirt bottom(A=12

mm).

Replace the piston and piston rings if wear on the diameter is 0.05

mmmorethantheminimumvaluegiven(seetableing.40-41).

Note:Oversizepistonsof0.50and1.00mmareavailable.

Dimensions of pistons and cylinders, Logo

Logo can be found inside the piston

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Loading...

Loading...