8

11

9 10

A

8

- 22 -

DISASSEMBLY/REASSEMBLY

Never clean the ltering element 6 using solvents with a low

ashpoint.Thiscouldcauseanexplosion!

Makesurethattheretentionrings4 - 5 areinagoodcondition

andreplacethemiftheyaredamaged.

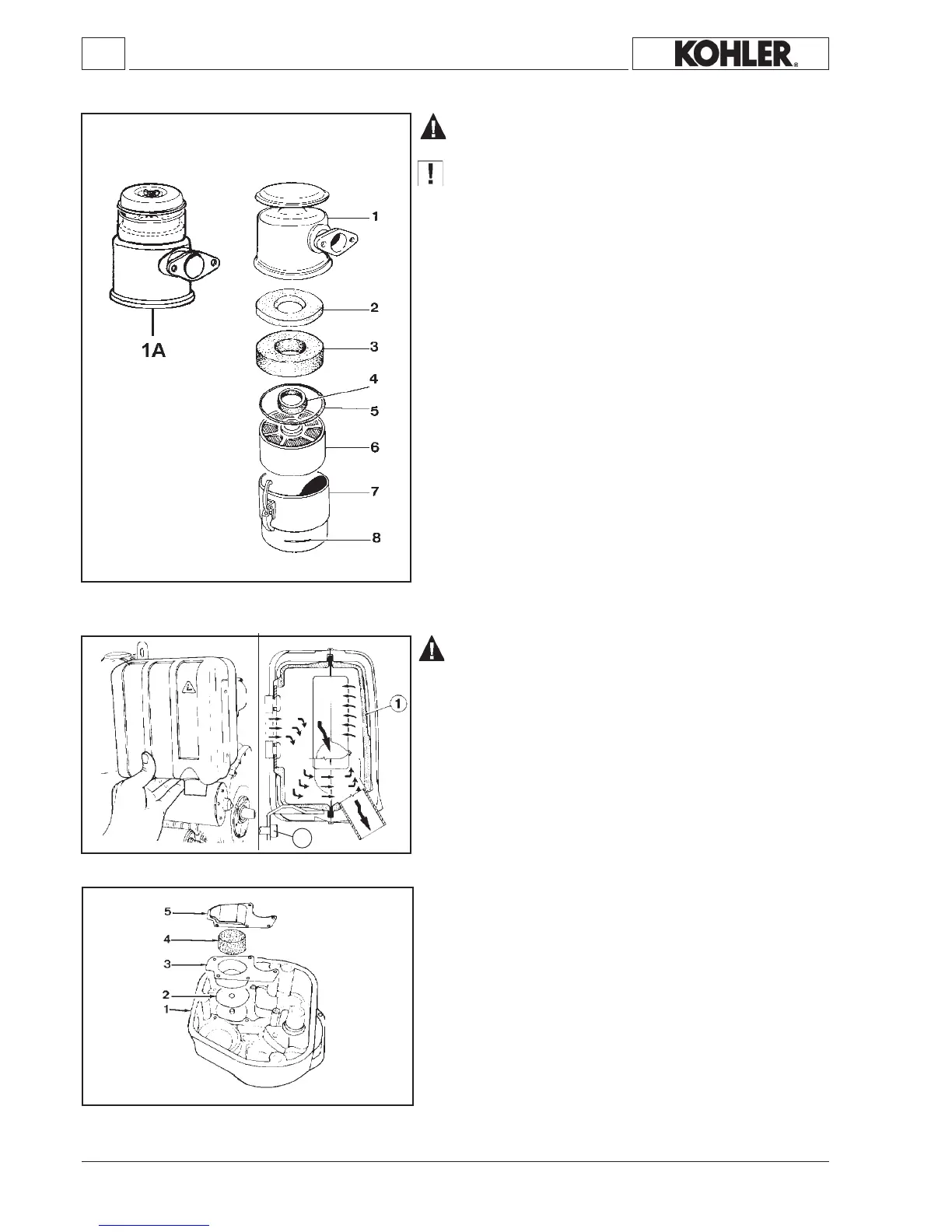

Oil-bath air cleaner (optional)

Components:

1 Uppershell

1AUpperunitwithseparatorpre-lter

2 Secondarylterelement

3Primarypolyurethane

4Internalsealring

5Externalrubbergasket

6 Lowermetallterelement

7 Lowercup

8Oillevelgauge

Characteristics of lter element 2:

madeofViledonsyntheticfabric,porosity120gr/m

2

,resin-covered.

Characteristics of lter element 3:

open-celledpolyurethanefoam;porosity45P.P.I..

Bothlterelementscanbewashedwithsoapandwaterforamaxi-

mumof10times.

Washthemetallter6 withDieselfuelBlowoutexcessfuelwithcom-

pressed air. See pages 14 and 15 for periodic maintenance details

andoilreplacement.

Allowtheexhaustmanifoldtocoolbeforedemountingitinorder

topreventscorchingandburns.

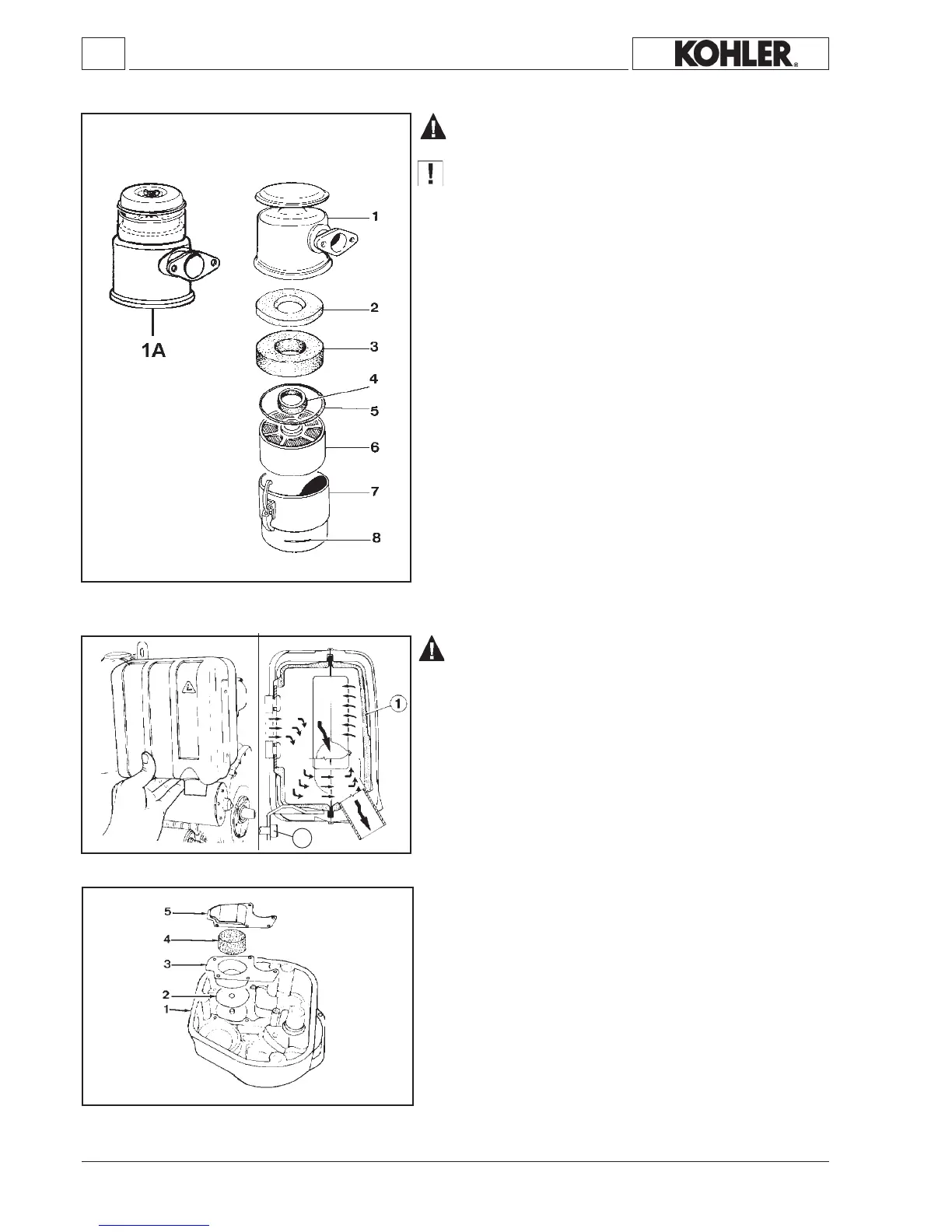

Mufer

Whenreassemblingreplacetheexhaustmanifoldgaskets.

Tightennutsto25Nm.

Themuferdesignincludesinternalsoundabsorbingpanels.

TightenthebearingnutsandscrewAtoa25Nmtorquevalue.

Rocker arm cover breather system

Thecrankcasebreathersystemislocatedinsidetherockerarmcover.

Checkthatdiaphragm 2isintact;washwithDieseloilandblowthrou-

ghthesmallmeshelement 4withcompressedair.

Whenreassemblingxbox3withLoctite"Form-a-gasketNo.6"and

screwplate5.Alsoseebelow.

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

Loading...

Loading...