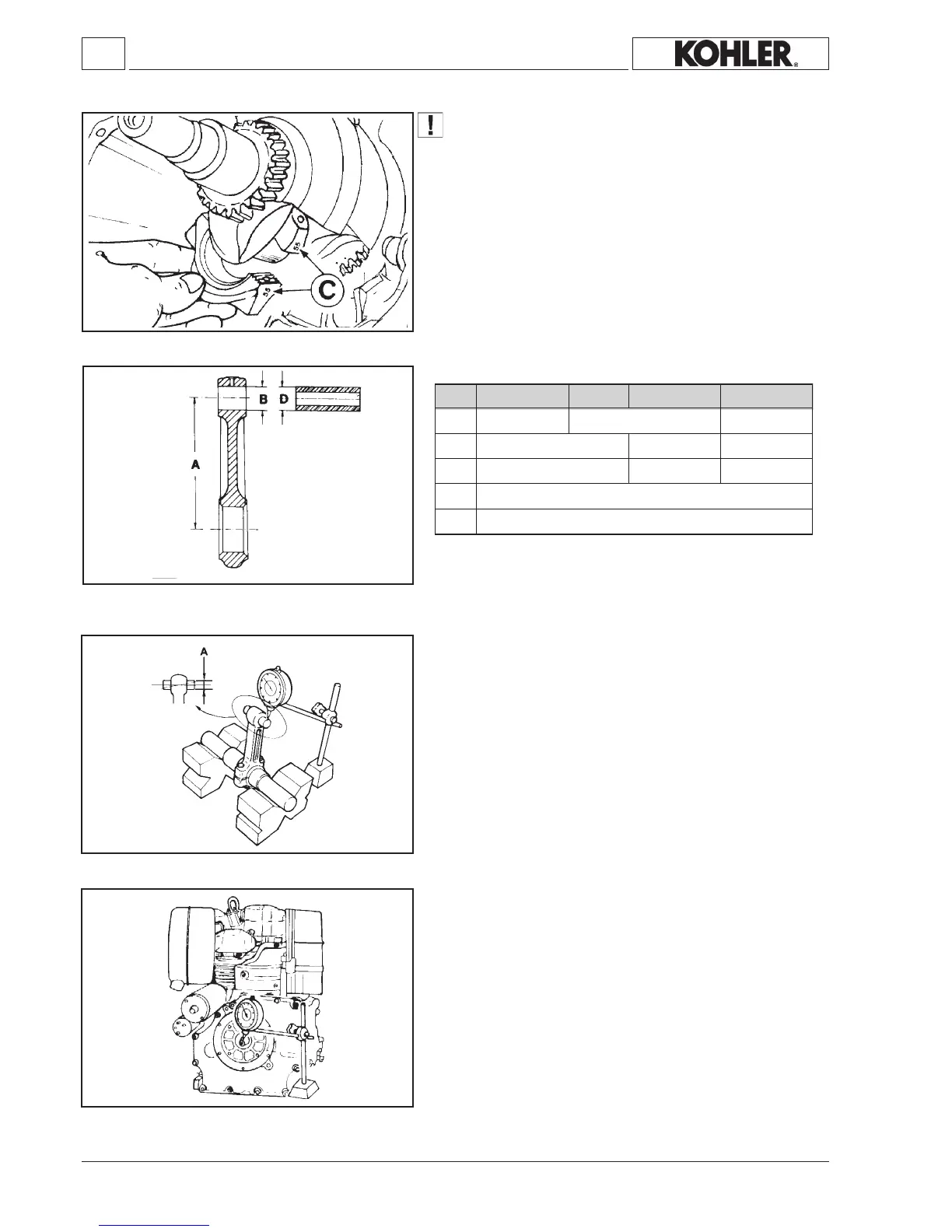

A

30,001÷079,99 30,011÷079,901 30,521÷79,421

B

020,02÷010,02 020,22÷010,22 020,32÷010,32

D

000,02÷599,91 000,22÷599,12 000,32÷599,22

)D-B(

520,0÷010,0

)D-B(

50,0

225 315 350

400-440

- 36 -

DISASSEMBLY/REASSEMBLY

Clearance

Limit

KD 225_315_350_400_440 Workshop Manual_cod. ED0053029330_1° ed_ rev.00

When remounting the big-end bearings, remember to thorou-

ghlycleanthepartsandgenerouslylubricatethemtoprevent

seizurewhentheengineisstartedupforthersttime

Connecting rod

Demount the connecting rod and proceed with the following inspec-

tions.

Thebig-endcapandbig-endbearthesamenumbers.

Whenremounting,mountthecapfromthesamesideasinCofthe

gure.

TightentheKD225boltstoa23Nmtorquevalue.

Tightentheboltstoa30NmtorquevalueforKD315-350-400-440.

Connecting rod, piston pin

Note: The connecting rod has no insert bearings. See g. 62 for

connectingrodbigenddiameter.

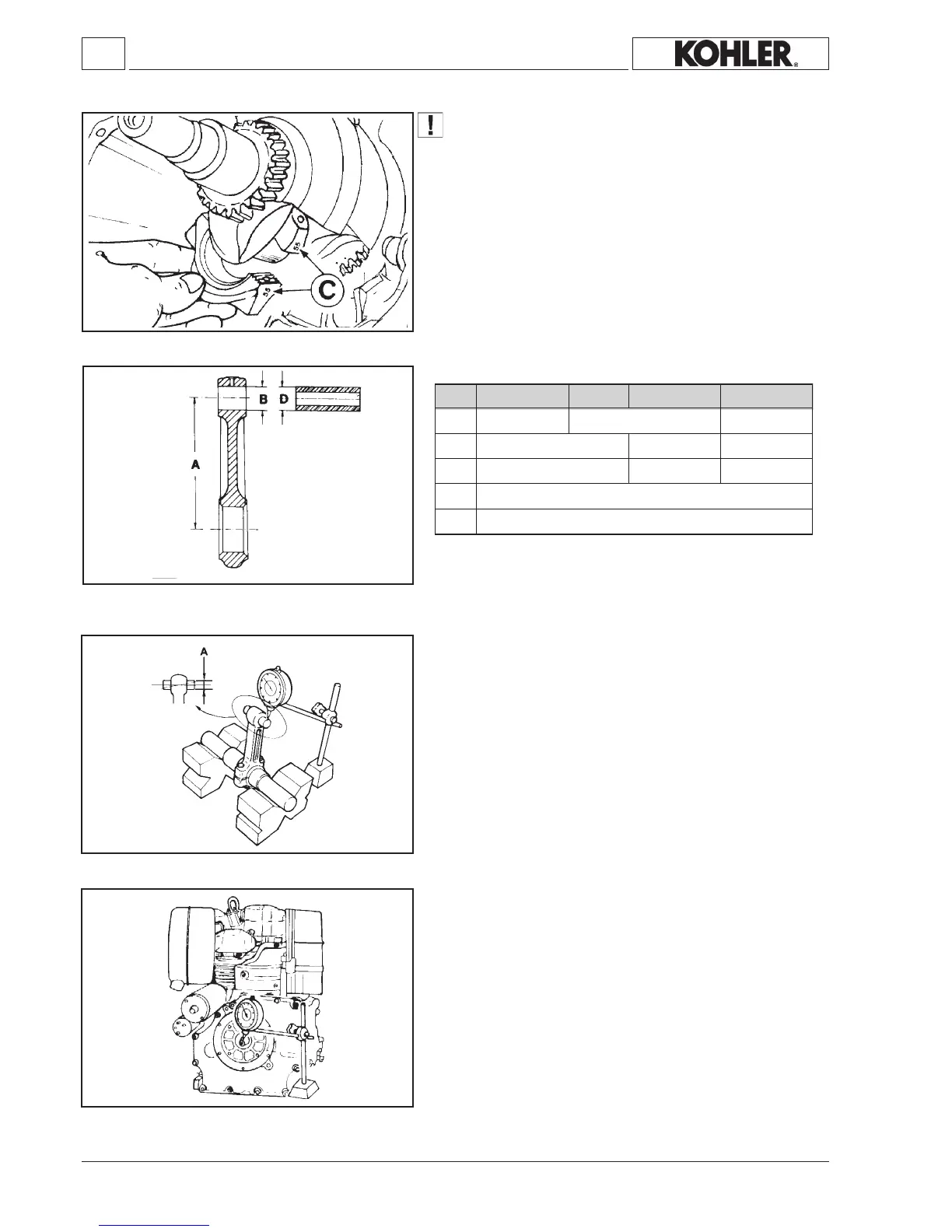

Connecting rod alignement

Useadialgaugeasshowninthegure.

Checkthataxes arealignedusingthepistonpin;axialmisalignment

A=0.015;limit0.03mm.

Crankshaft end play

Securetheenginetoametalbaseortable.Useadialindicatorwith

columnandmagneticbaseplate.Placethestylusonthecrankshaft.

Movethedrivingshaftbackandforthontheywheelside.

Endplayshouldbe0.05-0.25mm;itisnotadjustable.

Loading...

Loading...