140-3 SERIES

11-57

STRUCTURE AND FUNCTION, MAINTENANCE STANDARD OUTLINE OF CRI SYSTEM

OUTLINE OF CRI SYSTEM

OUTLINE

The CRI system detects the condition of the engine (engine speed, accelerator angle, cooling water tempera-

ture, etc.) from various sensors, and uses a microcomputer to carry out overall control of the fuel injection

amount, fuel injection timing, and fuel injection pressure to operate the engine under the optimum conditions.

The computer also carries out self-diagnosis of the main components, and if any abnormality is found, it carries

out diagnosis and sends an alarm to inform the operator. It also has a fail-safe function to stop the engine

according to the location of the abnormality and a backup function to switch the control method to make it possi-

ble to continue operation.

STRUCTURE

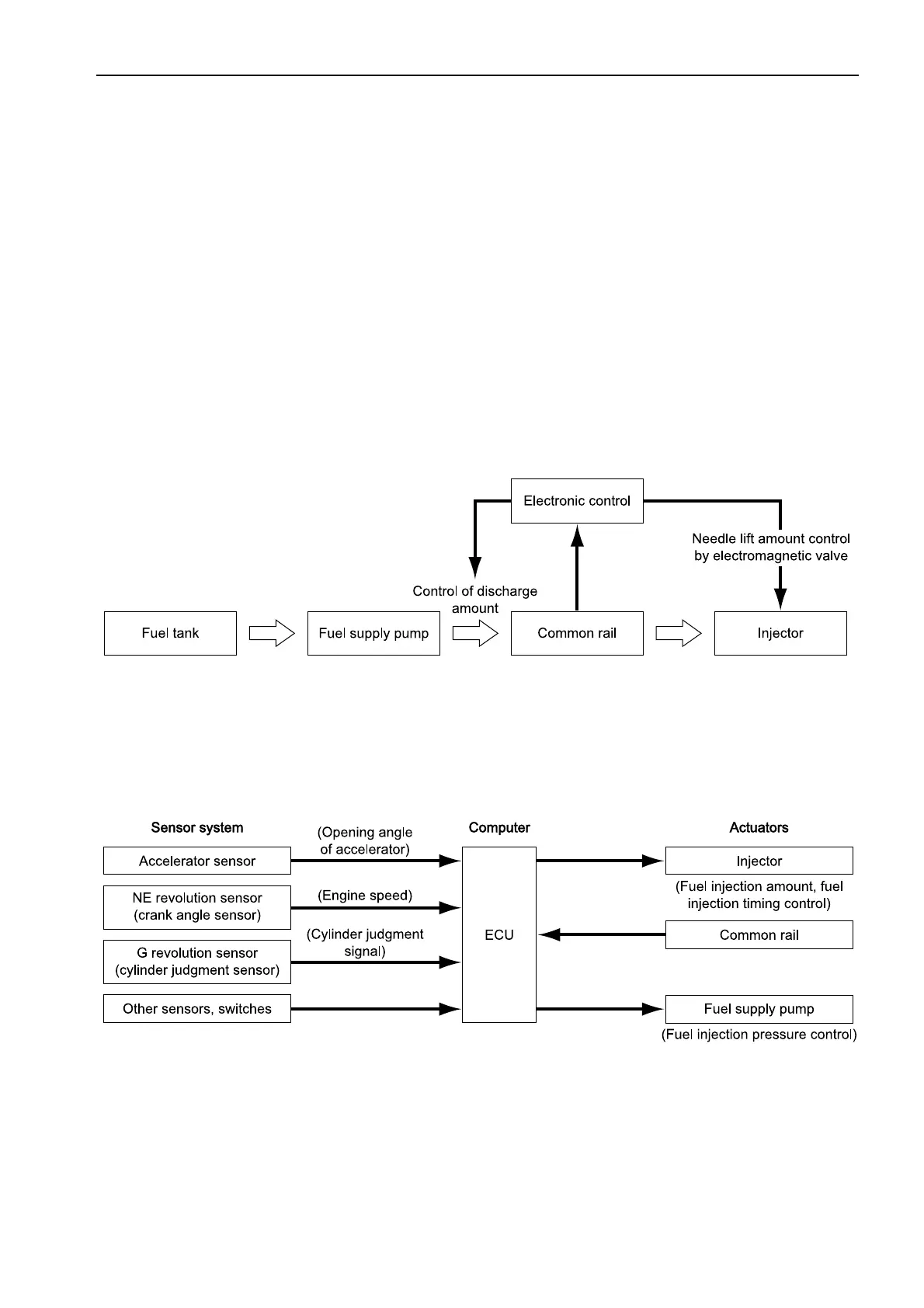

The CRI system can be divided in terms of function into the fuel system and control system.

1. Fuel system

The high-pressure fuel generated by the fuel supply pump goes from the common rail and is distributed to each

cylinder. The start and finish of injection is controlled by opening or closing the nozzle needle valve by using an

electromagnetic valve inside the injector.

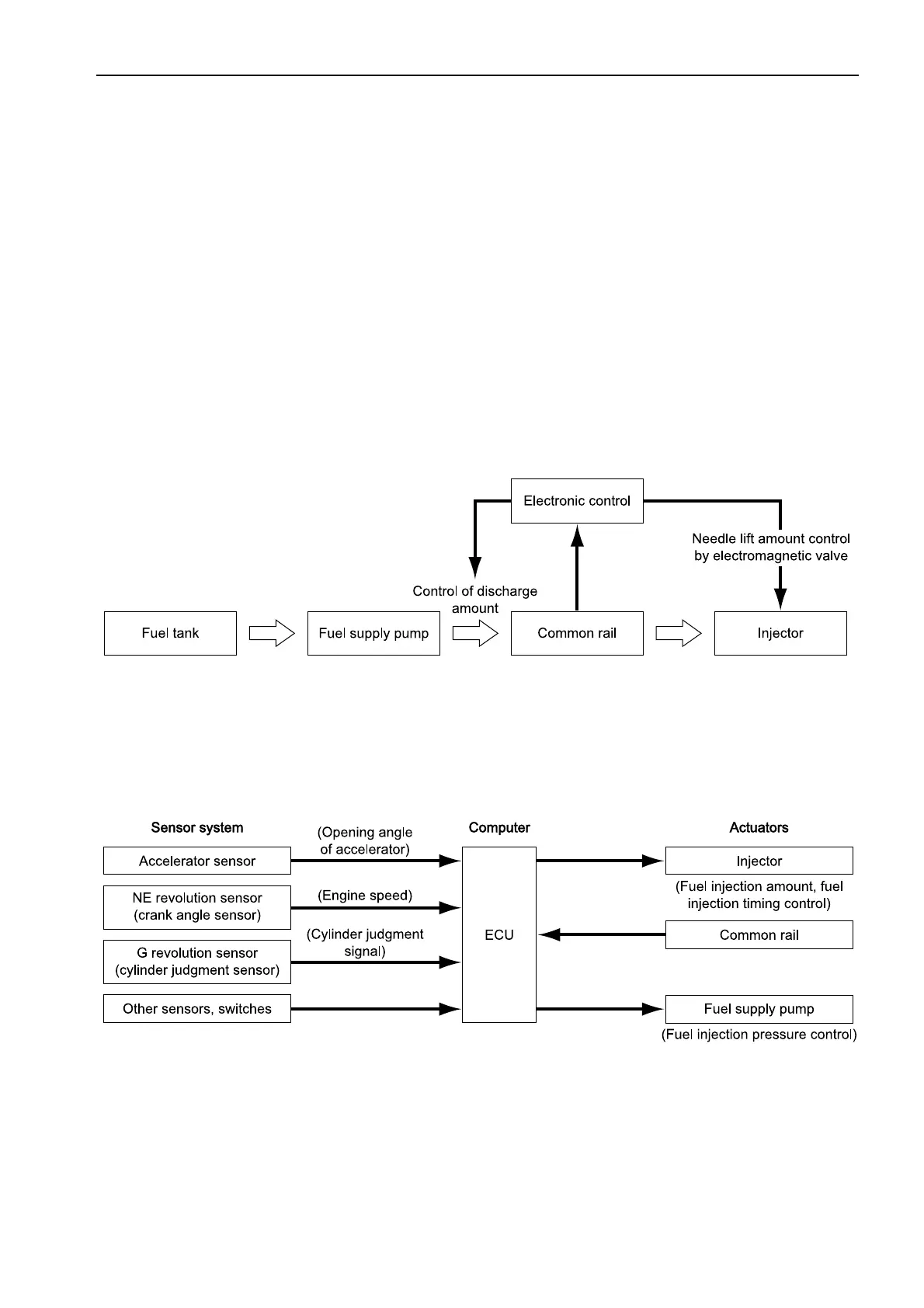

2. Control system

The ECU (Engine Control Unit) carries out control by calculating the length of time and the timing of sending

current to the injector by using the signals from the sensors installed to the engine and various parts of the

machine so that it injects a suitable amount at the suitable injection timing.

The control system and electrical components can be broadly divided into the sensors, computer, and actua-

tors.

Loading...

Loading...