12-18

140-3 SERIES

TESTING AND ADJUSTING TESTING AND ADJUSTING ALTERNATOR BELT TENSION

ADJUSTING SPEED SENSOR

ADJUSTING SPEED SENSOR

★ The G revolution sensor and NE revolution sen-

sor for the common rail type fuel injection system

cannot be adjusted.

★ Adjust the speed sensor as follows for the type

which uses an electronic system on the machine

and detects the signal from the flywheel ring

gear.

1.

Screw in sensor (1) until the tip contacts the tip of

the tooth of flywheel ring gear (2).

★ Check that there is no damage or metal pow-

der on the tip of the sensor when installing.

2

Thread:

Hydraulic sealant

2.

Turn sensor (1) back 1/2 – 2/3 turns.

★ This makes a clearance of 0.75 – 1.00 mm

between the tip of the sensor and the tip of

the gear tooth.

3.

Hold sensor (1) in position with nut (3).

3

Nut:

69 – 74 Nm {7.0 – 7.5 kgm}

TESTING AND ADJUSTING

ALTERNATOR BELT TENSION

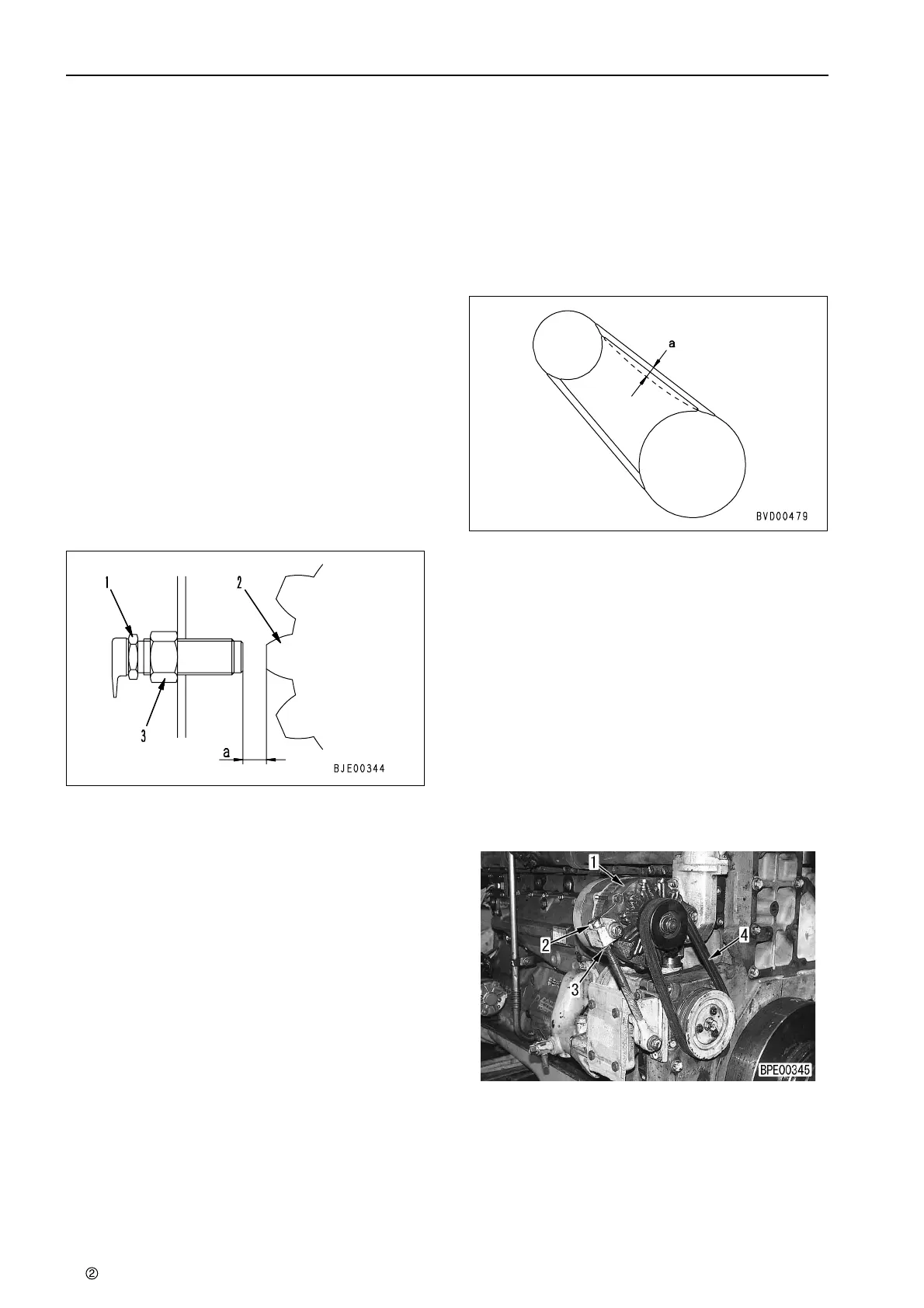

1. Inspecting

Measure deflection

a

when the belt is pressed

with a finger at a point midway between the

alternator pulley and drive pulley.

★ Pushing force: Approx.98 Nm {approx.10 kg}

★ Deflection (one belt): 13 – 16 mm

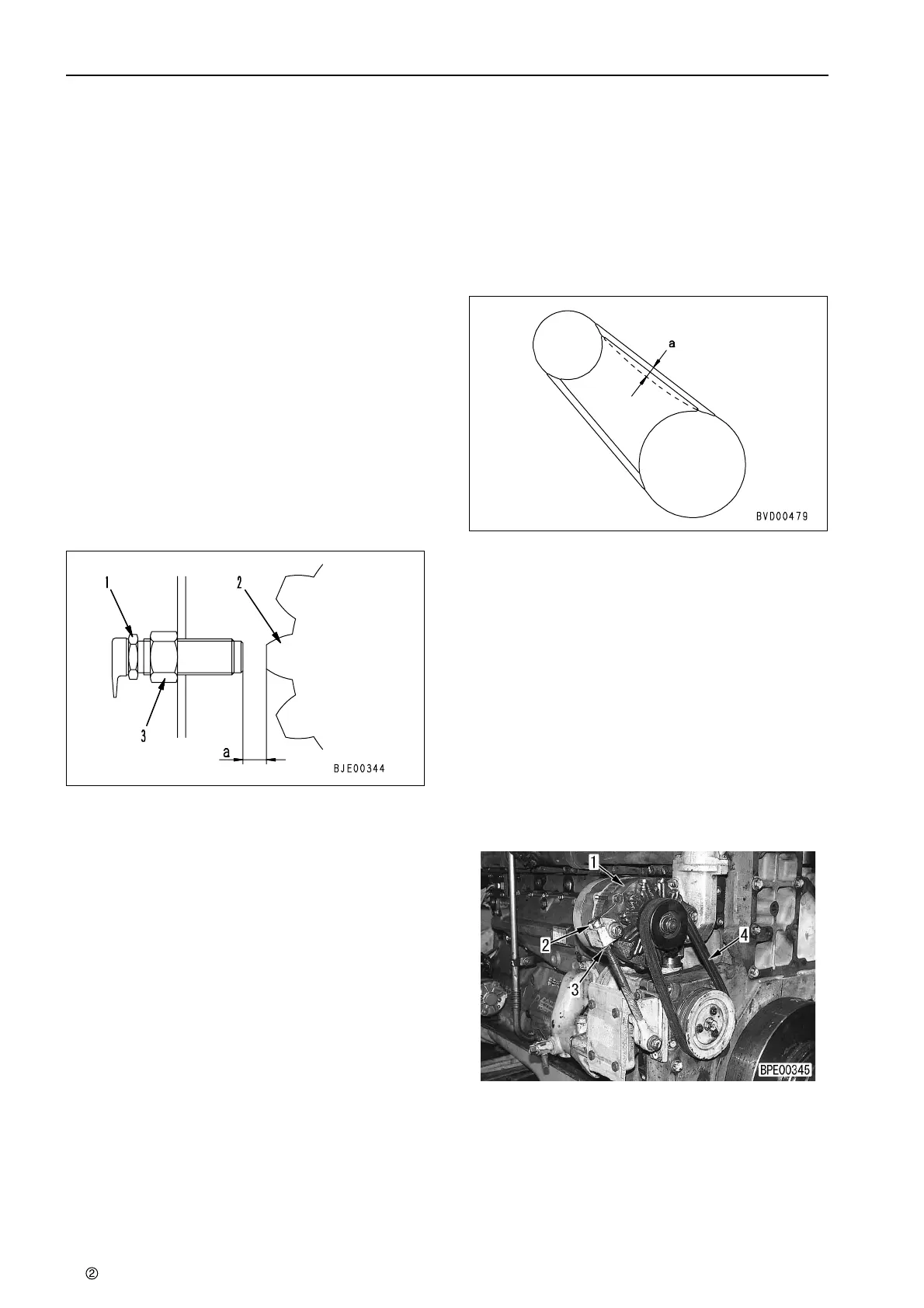

2. Adjusting

★ This makes a clearance of 0.75 – 1.00 mm

between the tip of the sensor and the tip of

the gear tooth.

★ If the deflection is not within the specified

range, adjust as follows.

1) Loosen 2 mounting bolts of alternator (1)

and 1 lock bolt of the bar.

2) Loosen locknut (2), move alternator (1) with

adjustment nut (3), and adjust the tension of

belt (4).

★ Deflection (one belt): 13 – 16 mm

3) Tighten locknut (2).

4) Tighten 2 mounting bolts of alternator (1)

and 1 lock bolt of the bar.

★ After adjusting, check the belt tension again.

Loading...

Loading...