140-3 SERIES

12-11

TESTING AND ADJUSTING MEASURING COMPRESSION PRESSURE

MEASURING COMPRESSION PRESSURE

When measuring the compression pressure, be

careful not to touch the exhaust manifold or muf-

fler, or to get caught in rotating parts.

★ Measure the compression pressure with the en-

gine warmed up. (Oil temperature: 40 – 60ºC)

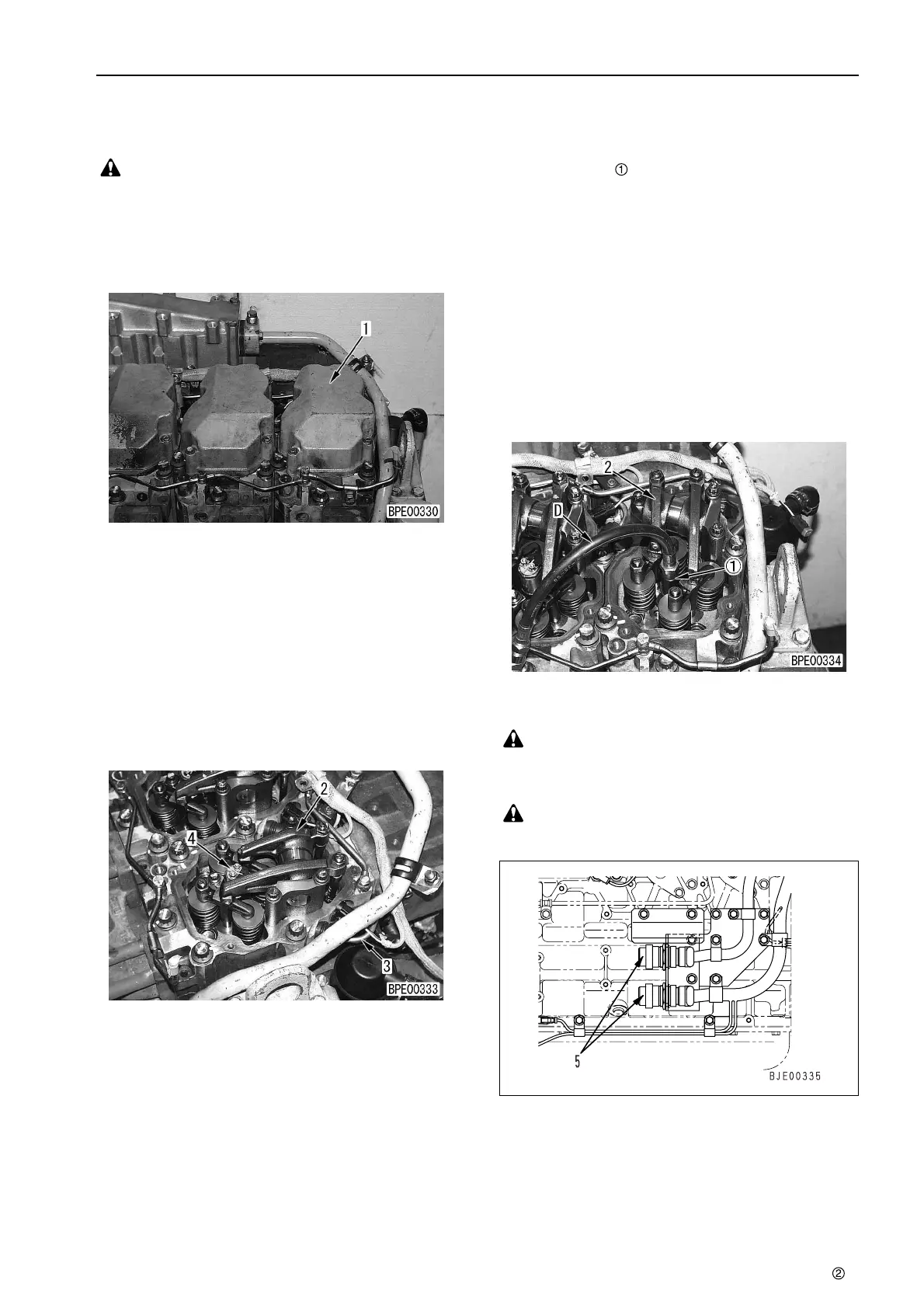

1.

Remove cylinder head cover (1).

2.

Remove rocker arm assembly (2).

3.

Disconnect fuel high-pressure tube (3), then re-

move the injector wiring harness and fuel injector

(4).

★ Disconnect the injector wiring harness from

the terminal at the injector end and the

bracket at the rocker housing end, then re-

move from the injector. (Loosen the terminal

nuts in turn.)

★ Pass a wire under the fuel passage protrud-

ing to the side, then pull up the injector (do

not twist or lever the top of the injector).

4.

Fit adapter of compression gauge

D

, then

connect to the compression gauge.

★ Coat the connection of the adapter and

gauge with a small amount of engine oil to

prevent leakage.

★ Hold the adapter in position with an injector

holder.

3

Mounting bolt:

58.8 – 73.5 Nm {6.0 – 7.5 kgm}

5.

Install rocker arm assembly (2), then adjust the

valve clearance.

3

Mounting bolt:

93 – 103 Nm {9.5 – 10.5 kgm}

★ For details, see ADJUSTING VALVE

CLEARANCE.

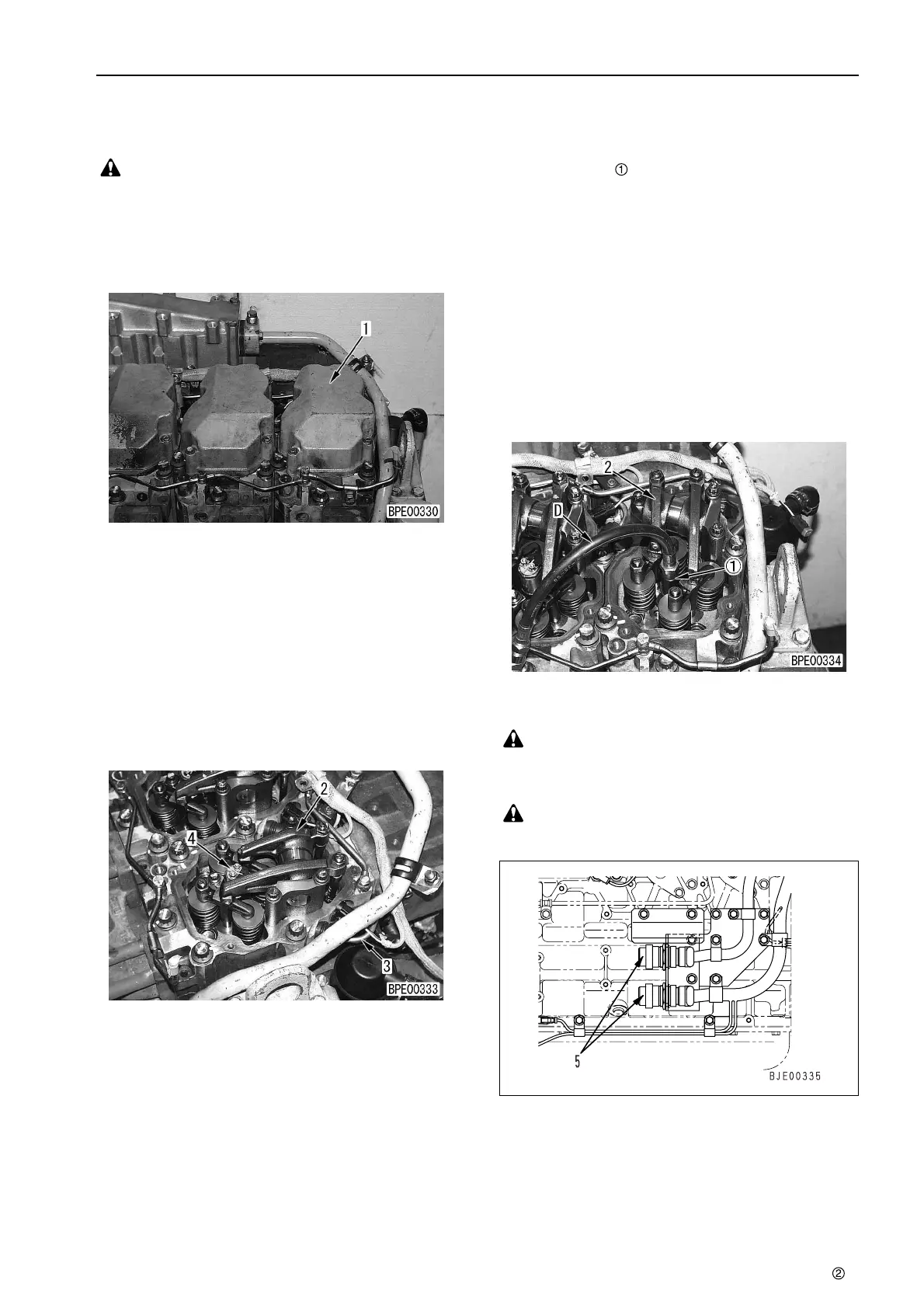

6.

Disconnect 2 engine central connectors (5).

If the connectors are not disconnected, there is

danger that the engine may start during the

measurement operation, so always be sure to

disconnect them.

Cover the connector at the controller end with

vinyl to prevent electrical leakage or short circuit

with the ground.

7.

Measure the compression pressure when the en-

gine is cranked with the starting motor.

★ Measure the compression pressure when

the gauge indicator is stable.

Loading...

Loading...