13-22

140-3 SERIES

DISASSEMBLY AND ASSEMBLY GENERAL ASSEMBLY OF ENGINE

GENERAL ASSEMBLY OF ENGINE

★ The following assembly procedures are for

SA6D140E-3 of HD325-6 specification. The

shapes, quantity, locations, etc. of some parts of

a machine assembled actually may be different

from the following explanation. Take care.

Preparation work

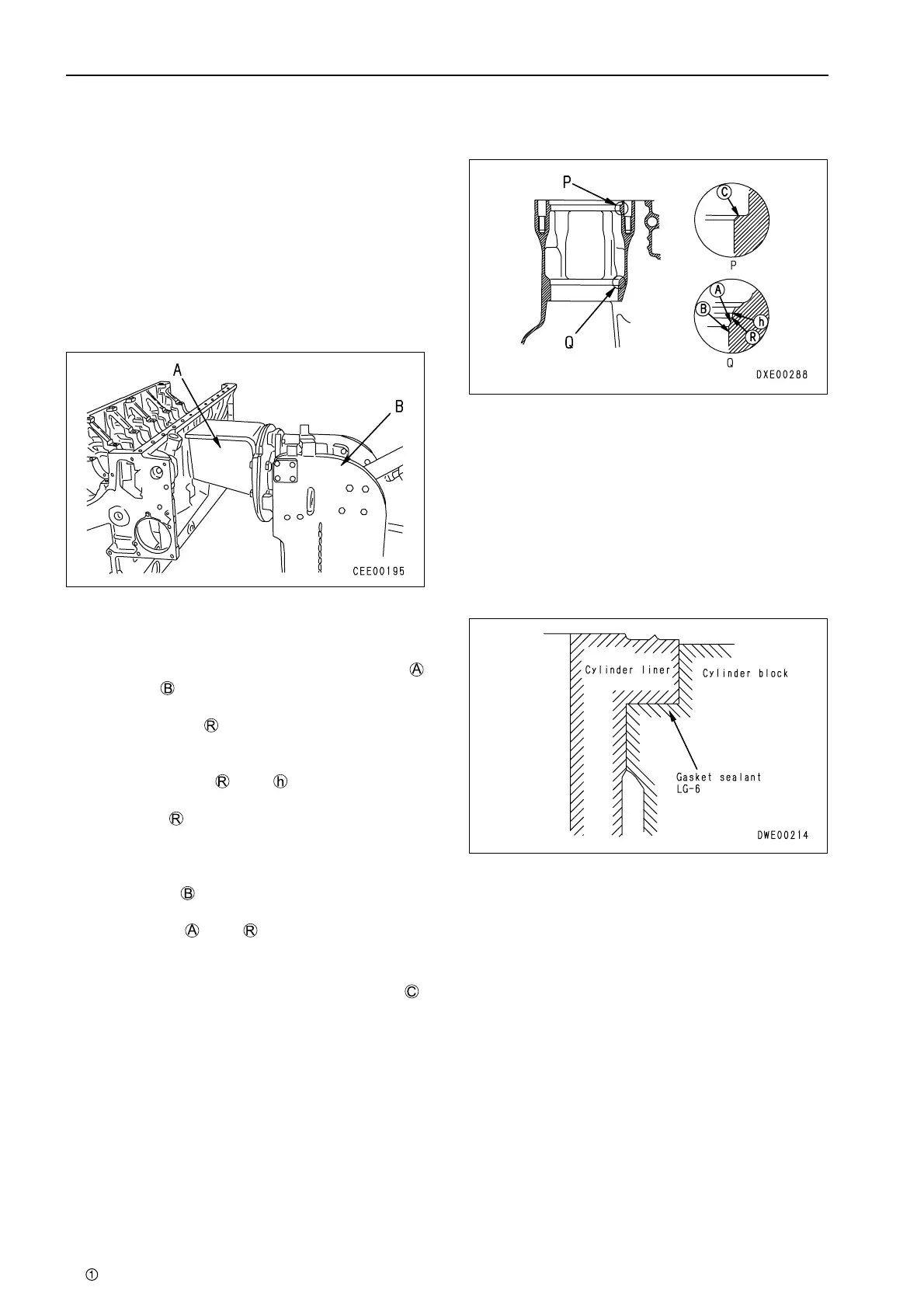

• Install adapter "

A

" to the cylinder block, then

sling the cylinder block and set it to engine over-

haul stand "

B

".

• Before inserting the cylinder liners, prepare the

cylinder block according to the following proce-

dure.

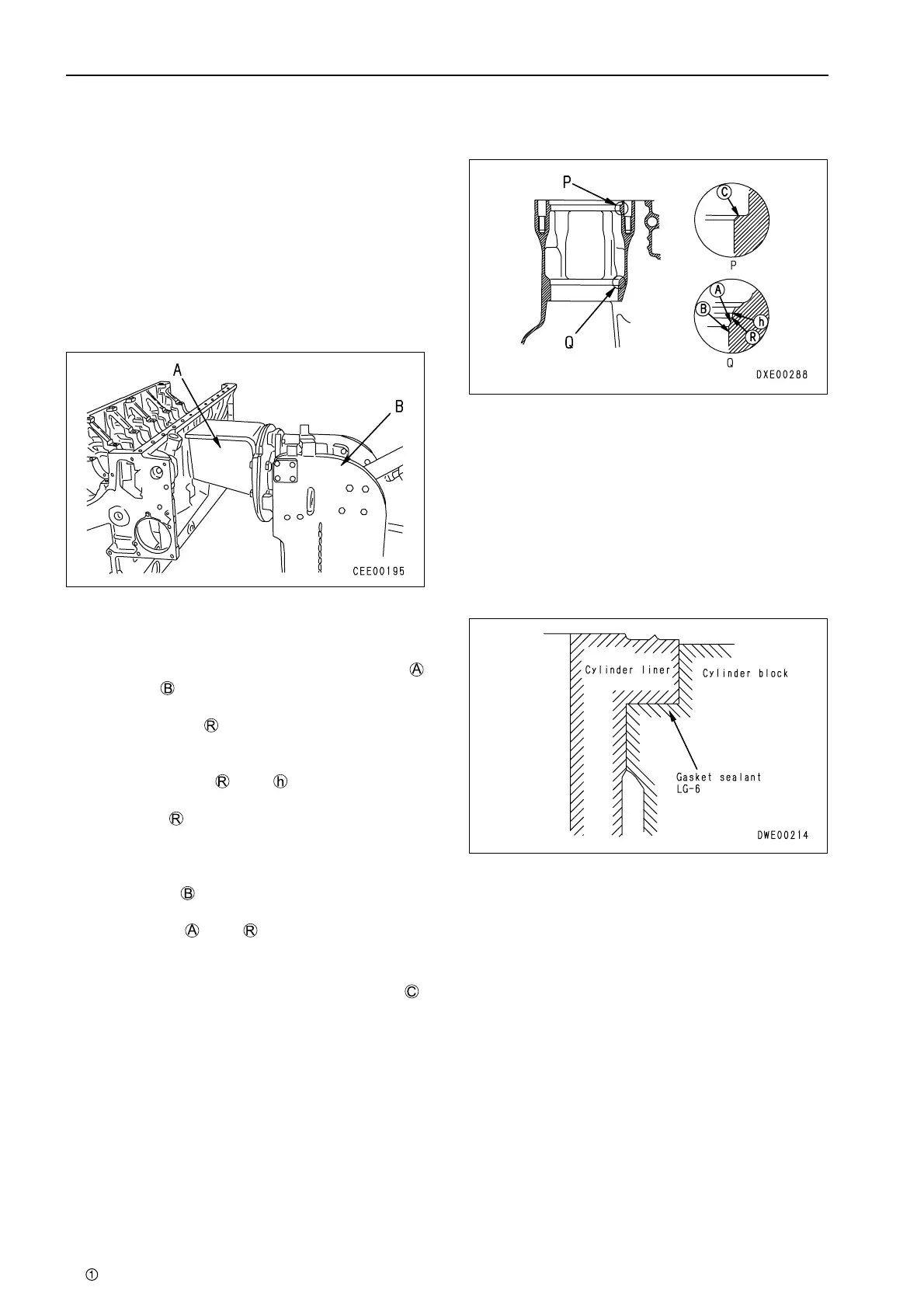

1) Remove the rust and scales from faces

and with sandpaper, etc. until the

machined surface is exposed.

2) Polish part with sandpaper of about No.

60 until it becomes a smooth rounded sur-

face.

3) Polish parts and with sandpaper of

about No. 60 until they become smooth.

If part is sharp or has burrs, finish it with

a scraper or sandpaper.

Finish this surface particularly smoothly so

that it will not damage the O-ring.

4) If face is so pitted that it cannot be

repaired, replace the cylinder block.

5) If faces and are pitted, finish them

smoothly.

6) Check the counterbored part and remove

burrs and fins. If chips or dust is on face ,

the liner does not fit and water may leak and

the liner does not project sufficiently.

★ If the counterbored part is drooping, cor-

roded, or pitted, repair it.

1. Cylinder liner

★ Replace the liner O-ring and clevis seal with new

ones just before installing the liner.

• Method of fitting liner O-ring and clevis seal

1) Make sure that the cylinder liner O-ring

groove and periphery of the liner are not

roughened because of rusting or pitting.

• If the above items are roughened be-

cause of rusting or pitting, water may

leak. Accordingly, replace the liner with

new one.

Loading...

Loading...