.

MAINTENANCE

SERVICE PROCEDURE

LUBRICATING

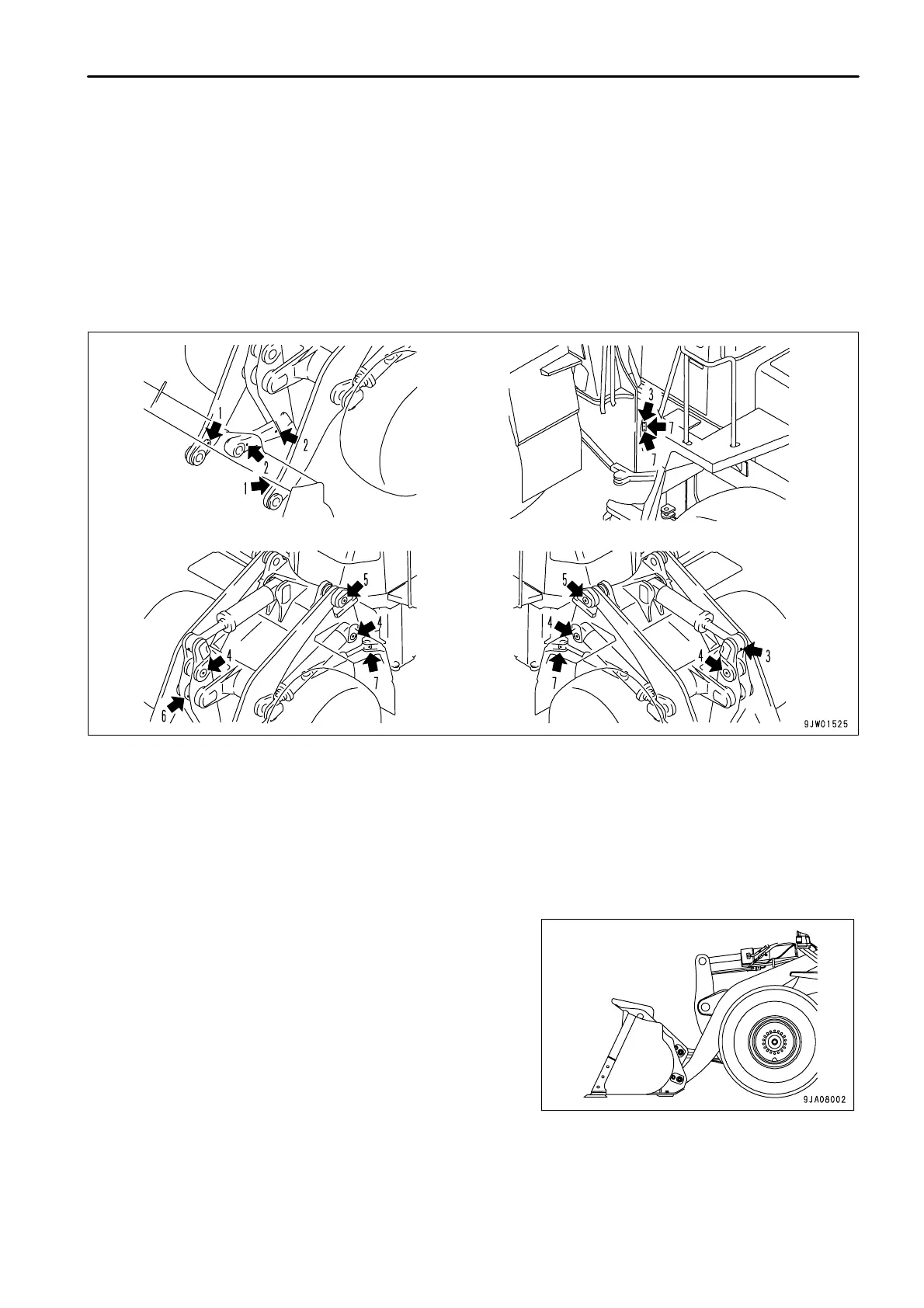

1.

Using a grease pump, pump in grease through the grease fittings marked by the arrows.

2.

After greasing, wipe off any old grease that was pushed out.

NOTICE

When working on jobsites where heavy-duty operations are frequent or when working continuously for more than eight hours,

shorten the lubrication interval and carry out lubrication more frequently.

For the initial 50 hours, carry out lubrication every 10 hours.

(1)

(2)

(3)

(4)

Bucket pin (2 places)

Bucket link pin (2 places)

Dump cylinder pin (2 places)

Lift cylinder pin (4 places)

(5)

(6)

(7)

Lift arm pivot pin (2 places)

Bell crank pin (1 place)

Steering cylinder pin (4 places)

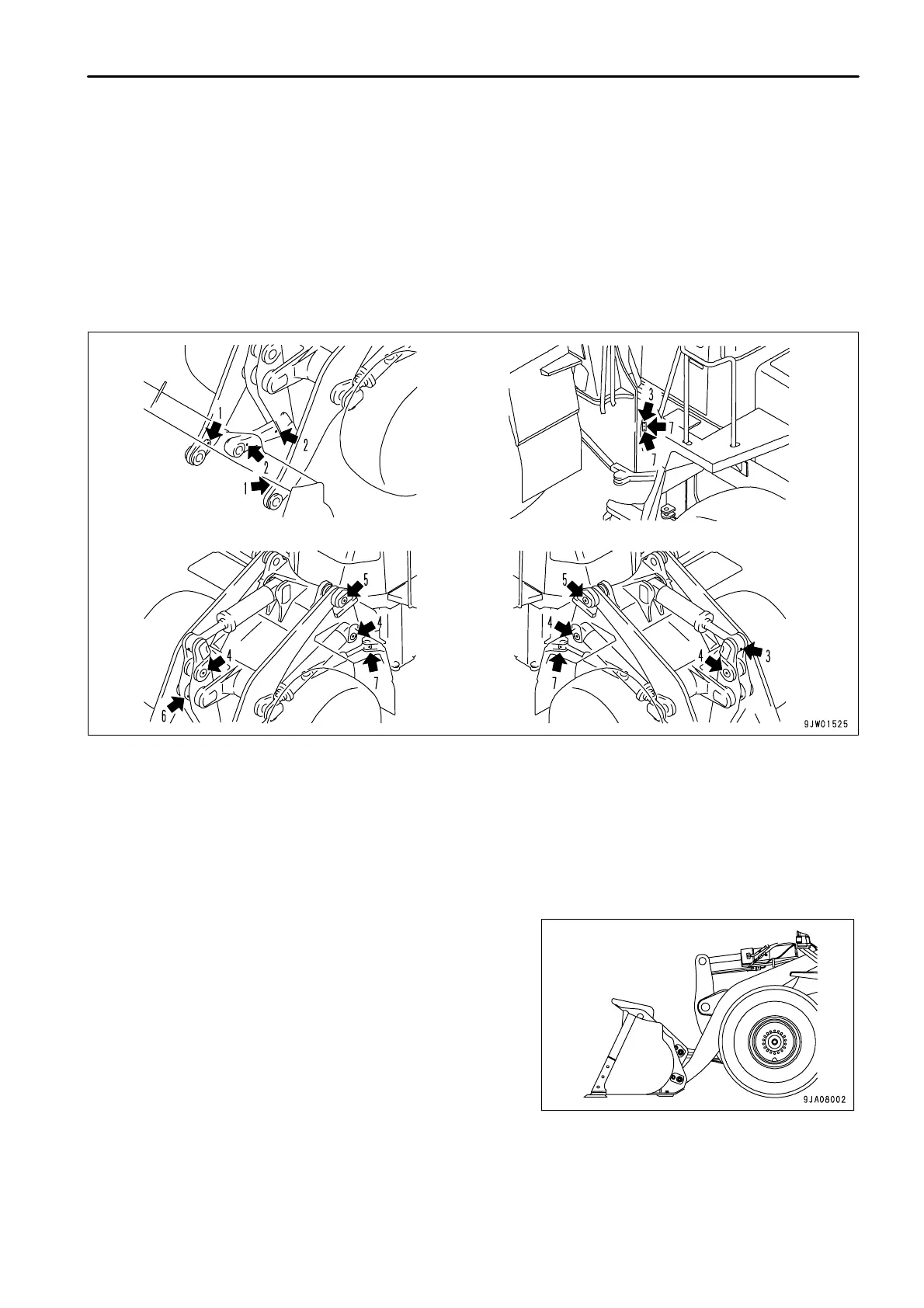

When carrying out greasing of bucket pin (1), lift arm pivot pin (5), and bell crank pin (6), set the work equipment to

the following posture.

Lower the bucket to the ground and set it horizontally.

4 - 47

Loading...

Loading...