.

MAINTENANCE

SERVICE PROCEDURE

EVERY 1000 HOURS SERVICE

Maintenance for every 50, 100, 250 and 500 hours service should be carried out at the same time.

REPLACE FUEL MAIN FILTER CARTRIDGE

WARNING

After the engine has been operated, all parts are at high temperature, so do not replace the filter immediately. Wait for all parts

to cool down before starting the operation.

High pressure is generated inside the engine fuel piping system when the engine is running.

When replacing the filter, wait for at least 30 seconds after stopping the engine to let the internal pressure go down before

replacing the filter.

Do not bring any fire or flame close.

NOTICE

Genuine Komatsu fuel filter cartridges use a special filter that has highly efficient filtering ability. When replacing the filter

cartridge, always use a genuine Komatsu part.

The common rail fuel injection system used on this machine consists of more precise parts than the conventional injection

pump and nozzle.

If any part other than a genuine Komatsu filter cartridge is used, dust or dirt may get in and cause problems with the injection

system. Always avoid using substitute parts.

When carrying out inspection or maintenance of the fuel system, pay more attention than normal to the entry of dirt. If dirt is

stuck to any part, use fuel to wash it off completely.

Prepare a filter wrench

1.

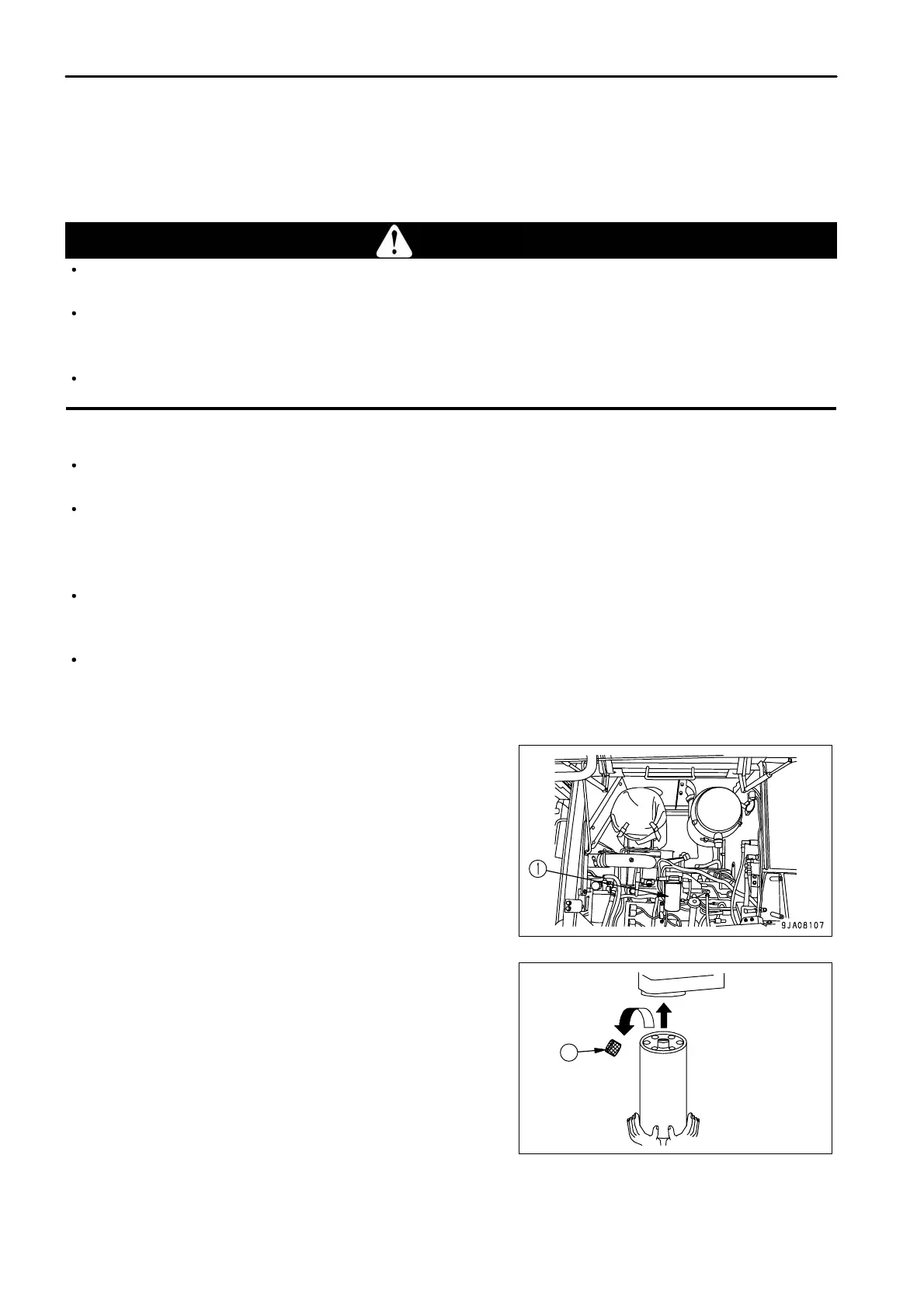

Open the engine side cover on the right side of the chassis.

2. Set the container to catch the fuel under the filter cartridge.

3.

Using a filter wrench, turn filter cartridge (1) counterclockwise

on remove it.

4. Clean the filter holder.

NOTICE

Do not fill the filter cartridge with fuel.

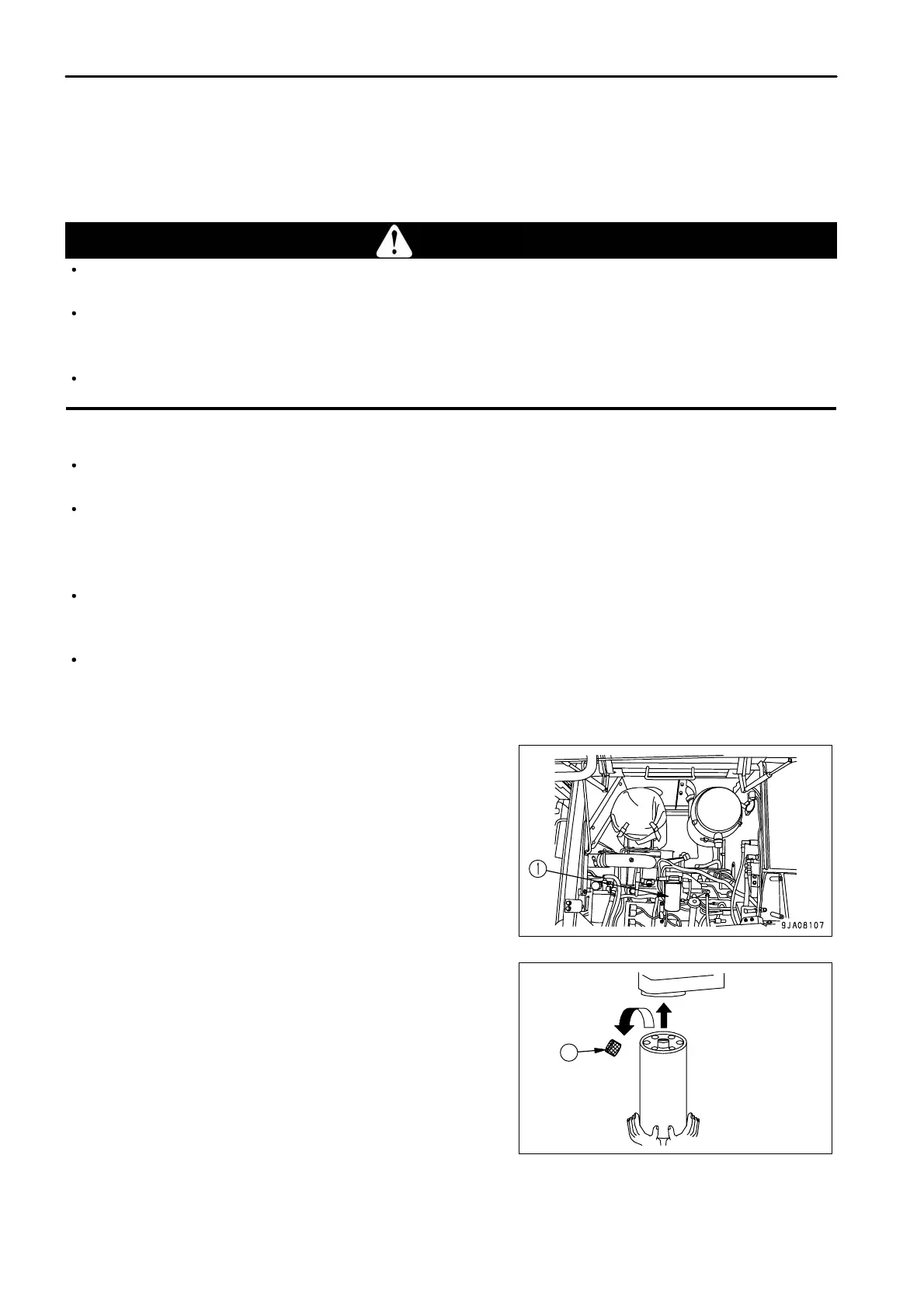

Cap (A) is installed to prevent dirt from entering the inside of the filter

cartridge.

5.

Coat the packing surface of the filter cartridge with oil.

9 J A 0 7 6 3 9

A

6. Remove filter cartridge cap (A) and install to the filter holder.

4 - 52

Loading...

Loading...