WARNING

If worn or damaged tires are used, they may burst and

cause serious injury or death.

To ensure safety, do not use the following tires.

Wear

• Tires with the tread groove depth of 15 % or less

of that of a new tire

• Tires with the abnormal wear such as uneven wear

or stepped wear

Damage

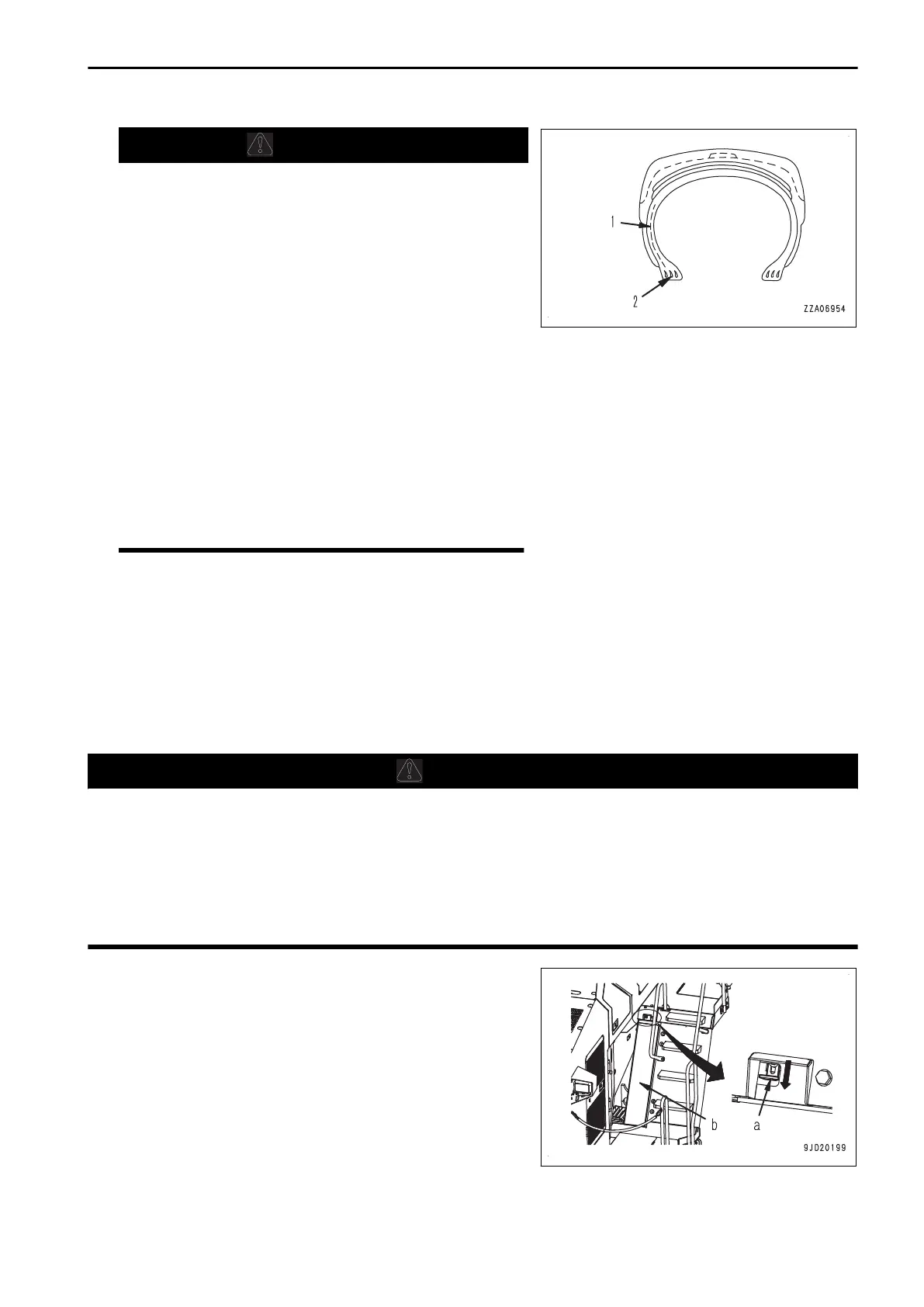

• Tires with damage that has reached cords (1), or

with cracks in the rubber

• Tires with cut or broken cords (1)

• When tires are peeled (separated)

• Tires with damaged bead (2)

• Leaking or improperly repaired tubeless tires

• Deteriorated, deformed or abnormally damaged

tires, which do not seem usable.

22.

Check the wheel rims.

Check that the wheel rims and rings are free from deformation, damage caused by corrosion, and cracks.

In particular, check the side rings, lock rings and rim flanges thoroughly.

METHOD FOR CHECKING BEFORE STARTING

Always check the items in this section before starting the engine each day.

METHOD FOR CHECKING WATER SEPARATOR, DRAINING WATER AND SEDI-

MENT

WARNING

• Immediately after the engine is stopped, all of parts are still very hot. Avoid draining water or re-

moving the transparent cup.

Wait for all of parts to cool down before starting the work.

• When the engine has run, high-pressure is generated in the engine fuel piping. When draining the

water or removing the transparent cup, wait for at least 30 seconds after stopping the engine to let

the internal pressure go down before starting the work.

• Do not bring any open flame close.

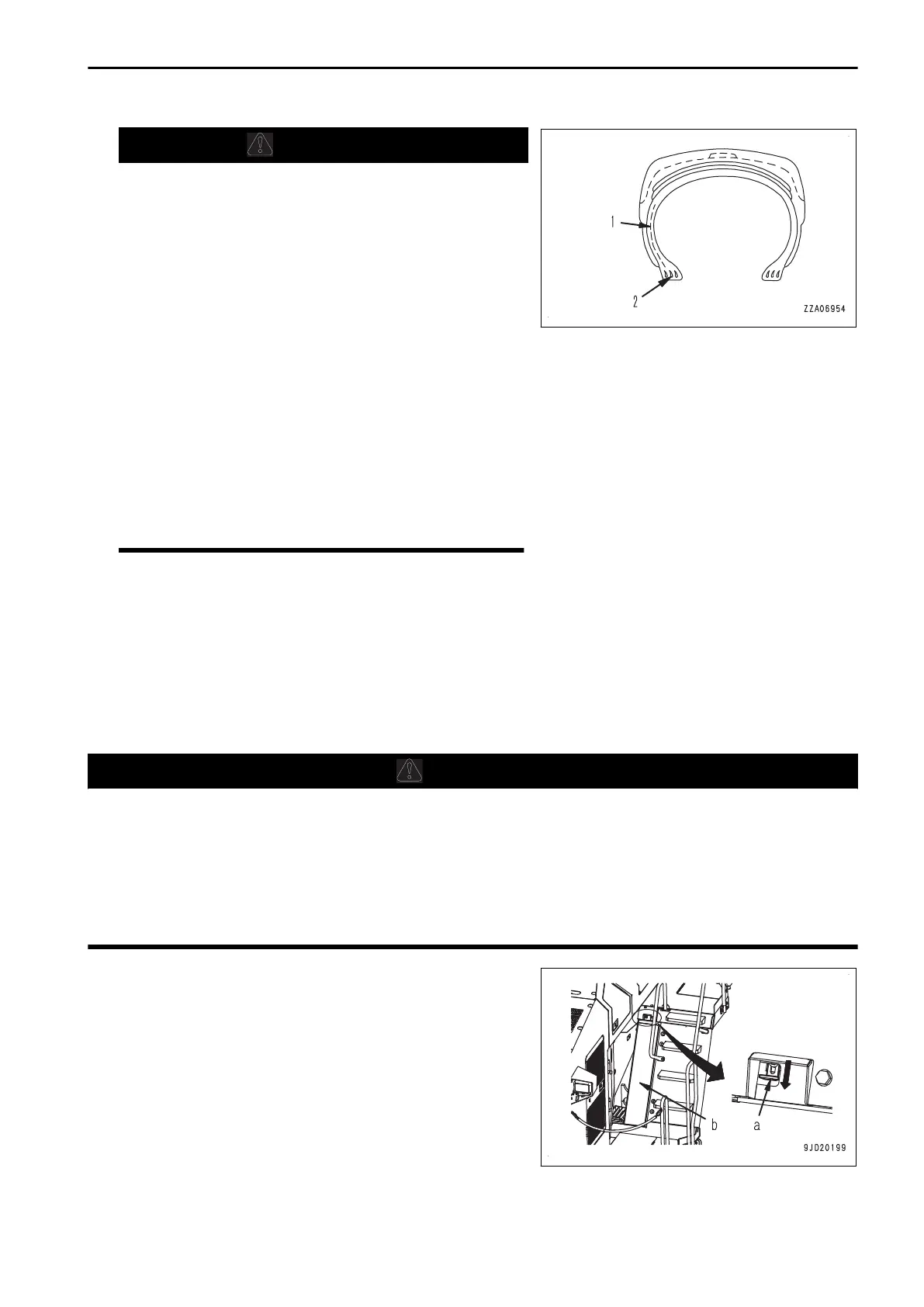

For the machine with rear fender, operate lever (a) downward,

and open cover (b) before the work.

OPERATION MACHINE OPERATIONS AND CONTROLS

3-171

Loading...

Loading...