1-S46

F2880, F3680, RCK72-F36, RCK72R-F36, RCK60-F36, RCK60R-F36, WSM

ENGINE

(3) Piston and Connecting Rod

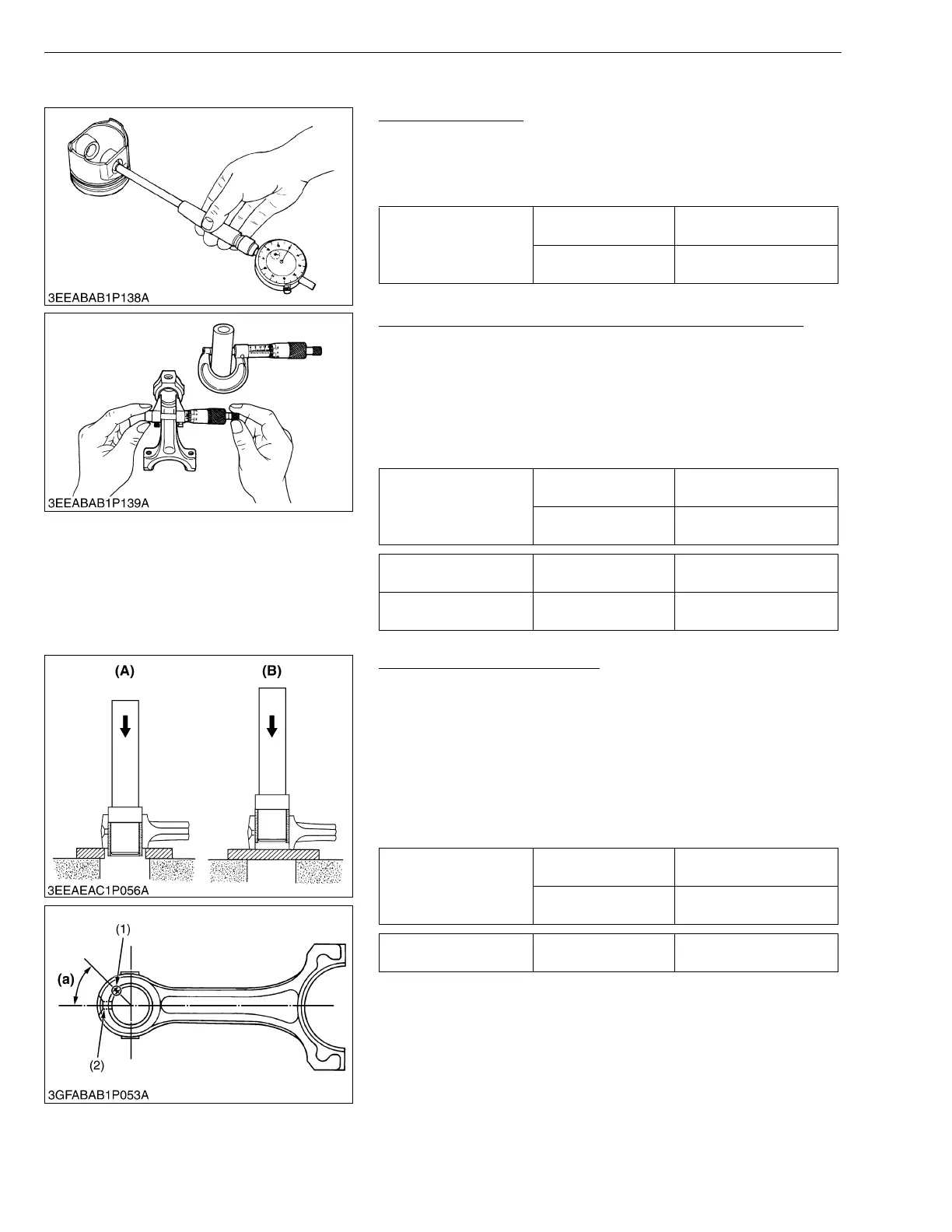

Piston Pin Bore I.D.

1. Measure the piston pin bore I.D. in both the horizontal and

vertical directions with a cylinder gauge.

2. If the measurement exceeds the allowable limit, replace the

piston.

W10304770

Oil Clearance between Piston Pin and Small End Bushing

1. Measure the piston pin O.D. where it contacts the bushing with

an outside micrometer.

2. Measure the small end bushing I.D. with an inside micrometer,

and calculate the oil clearance.

3. If the oil clearance exceeds the allowable limit, replace the

bushing. If it still exceeds the allowable limit, replace the piston

pin.

W10305740

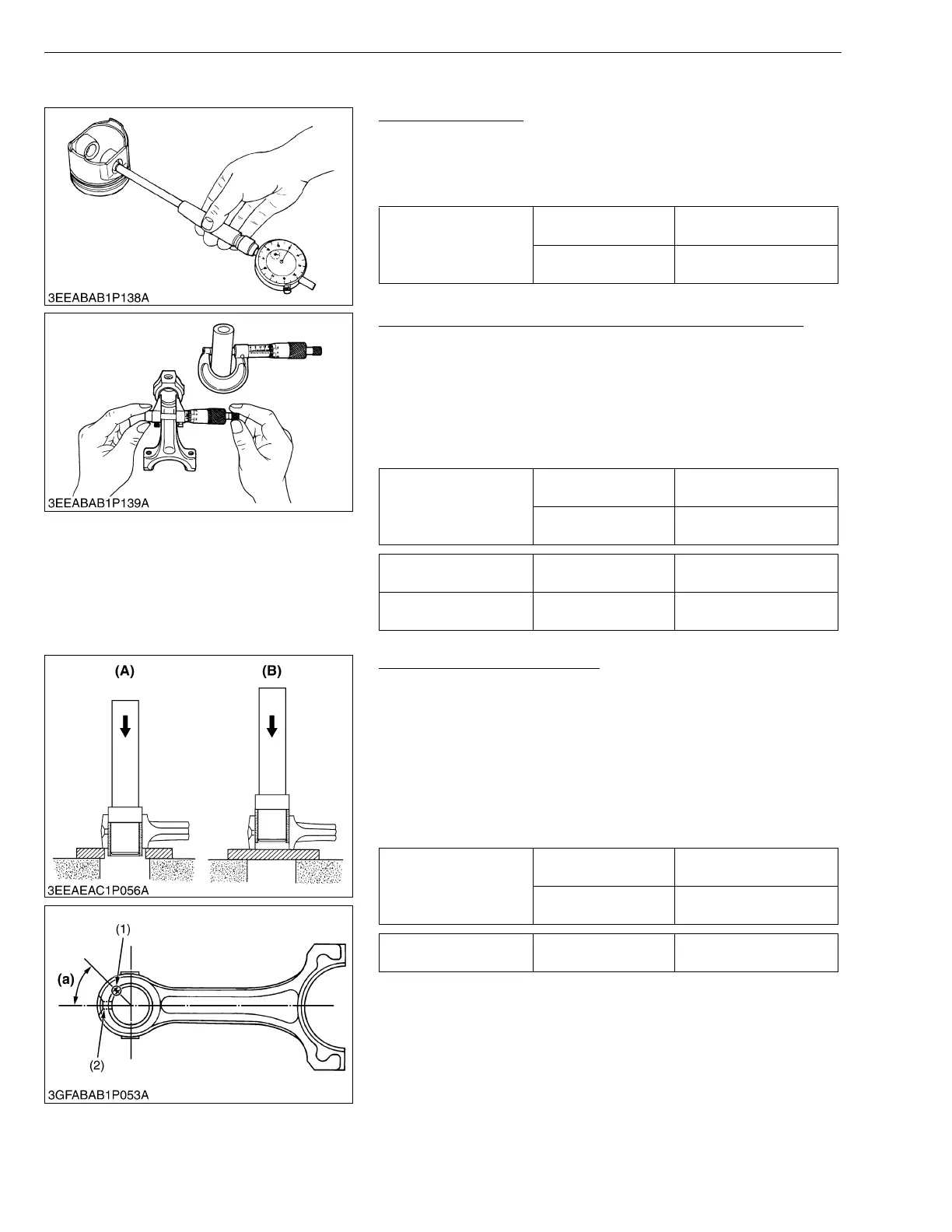

Replacing Small End Bushing

(When removing)

1. Press out the used bushing using a small end bushing replacing

tool. (See page “SPECIAL TOOLS”.)

(When installing)

1. Clean a new small end bushing and bore, and apply engine oil to

them.

2. Using a small end bushing replacing tool, press in a new bushing

(service parts) taking care to see that the connecting rod oil hole

matches the bushing hole.

W10307120

Piston pin bore I.D.

Factory spec.

22.000 to 22.013 mm

0.8661 to 0.8667 in.

Allowable limit

22.03 mm

0.8673 in.

Oil clearance between

piston pin and small end

bushing

Factory spec.

0.014 to 0.038 mm

0.00055 to 0.00150 in.

Allowable limit

0.15 mm

0.0059 in.

Piston pin O.D. Factory spec.

22.002 to 22.011 mm

0.8662 to 0.8666 in.

Small end bushing I.D. Factory spec.

22.025 to 22.040 mm

0.8671 to 0.8677 in.

Oil clearance between

piston pin and small end

bushing (Spare parts)

Factory spec.

0.015 to 0.075 mm

0.00059 to 0.00295 in.

Allowable limit

0.15 mm

0.0059 in.

Small end bushing I.D.

(Spare parts)

Factory spec.

22.026 to 22.077 mm

0.7885 to 0.7904 in.

(1) Seam

(2) Oil Hole

(A) When Removing

(B) When Installing

(a) 0.785 rad (45 °)

Loading...

Loading...