223

8 CO/O

2

Control

Deactivating CO control depending on the O

2

value

For a description, see chapter Optimising the CO Control

NOTICE

This function is only available via CMS Remote Software.

8.10.6 Checking the Combustion-related Limit Values

NOTICE

With O

2

trim is it essential to ensure that the burner burns safely and stably at maximum cor-

rectional intervention (0 % and 100 %), taking into account all environmental influences and

in every burner firing-rate range.

To do this, transverse the correction value both to 0 % and to 100 % at different firing-rate val-

ues (for CMS Remote Software see chapter Testing the Correction Effect).

8.10.7 Set and Optimise the CO Response Threshold on LT3-F

The basis for CO regulation is a digital signal CO greater/less than threshold value.

This signal is formed in the LT3-F and transferred to the burner controller via the LAMTEC

SYSTEM BUS (LSB).

1. Run the burner to a firing-rate between base fire and half fire.

2. Change the electronic ratio towards less air and/or more fuel (correction values 100%)

until the CO edge is detected; if necessary, increase the correctional range again.

Alternatively, you can keep it regulated at the CO edge. You must not change the firing-

rate for this purpose (MANUAL burner firing-rate controller). On the display of the CMS,

the signal dynamics must rise continuously.

NOTICE

If this display value of CMS reaches -32 in case of air reduction (display of Item 2 = – and Item

4 = 32) and +52 or +54 ( in case of air increase (display of Item 2 = + and Item 4 = 52 or 54),

the CO regulation has detected the CO edge and the optimisation point is saved.

Repeat at another firing-rate point.

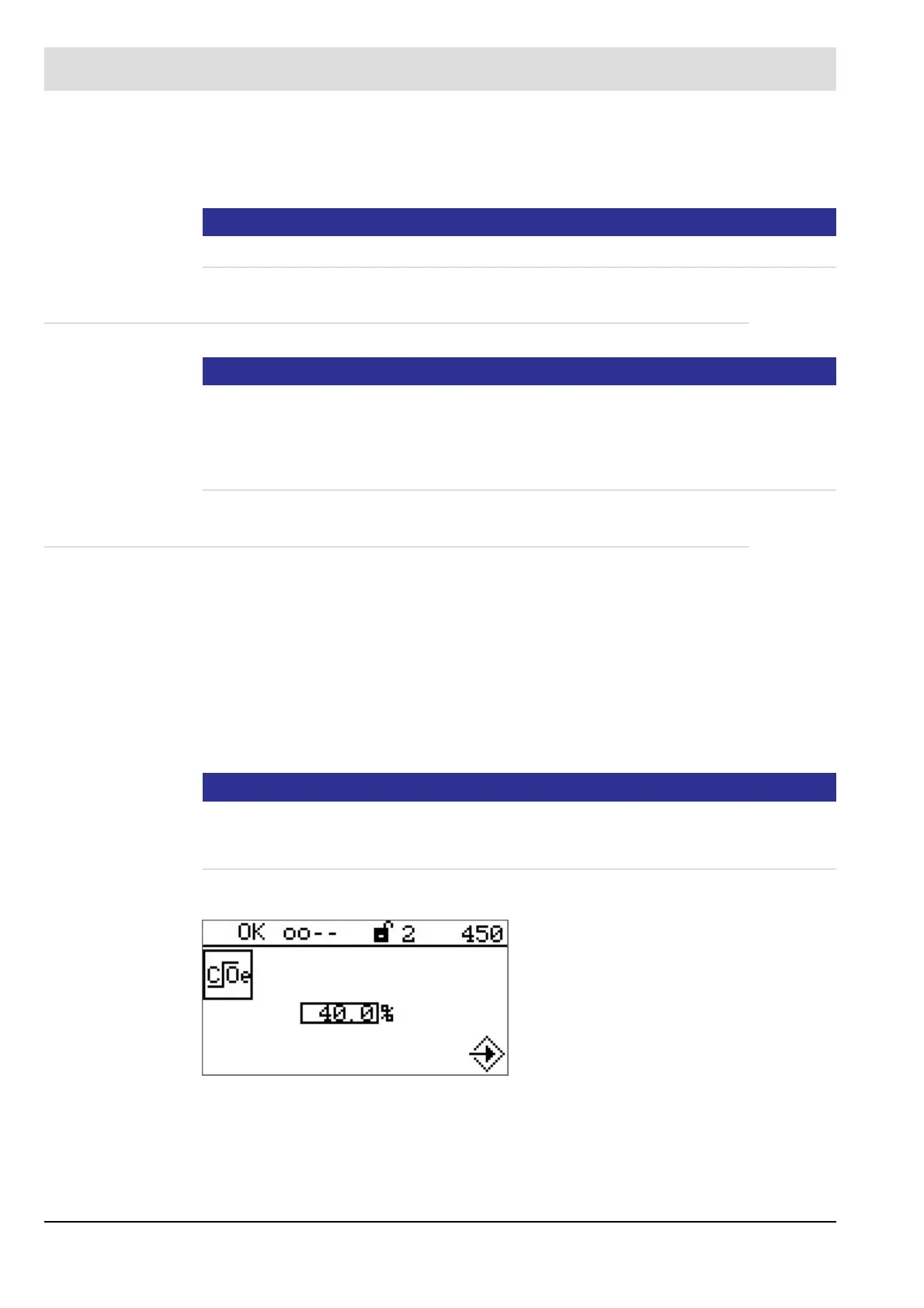

Fig. 8-14 ’Settings’ menu in the LT3-F

Can only be set in access level 2!

CO

e

trigger threshold. Switching threshold of

the CO

e

detection for LAMTEC CO/O

2

regu-

lation. Evaluation of the signal dynamics.

Settable in a range from 0 ... 100 %.

Factory setting: 40 %

< 40% trim becomes more sensitive

> 40% trim becomes less sensitive

Loading...

Loading...