11

PIAB = [(Required CFM - Minimum CFM) / (Maximum CFM - Minimum CFM)] * 100

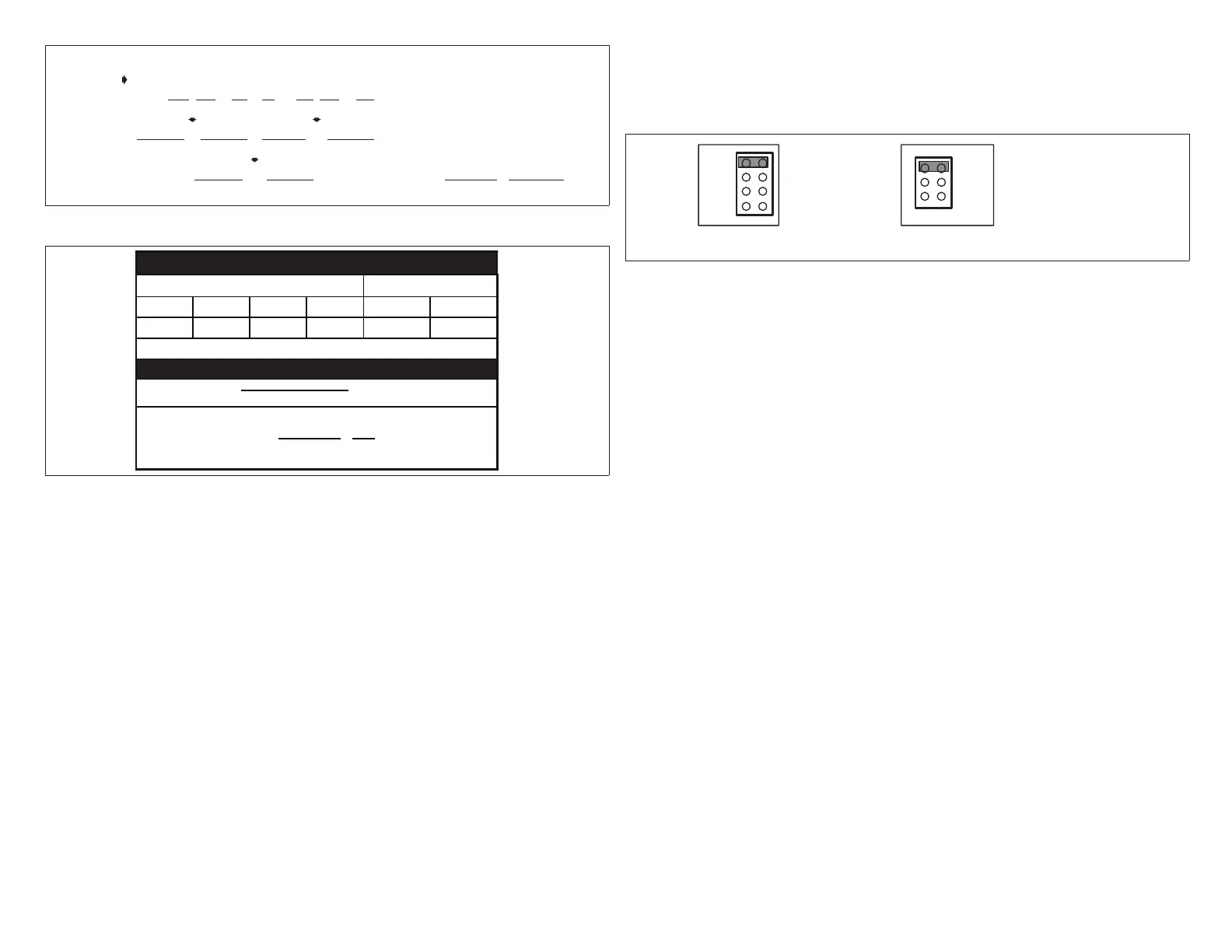

Sample CFM

RequiredMinimum Maximum Minimum

Sample PIAB = ([___920 -450 ] / [ 2000 -450 ]) x 100

==

Sample PIAB =([ 470 ] / [1550]) x 100

=

Sample PIAB =[0.303] x 100 = 30 %

Figure 10. PIAB Calculation Example

example

CFM

values

Require

d

CF

M

CFM

Zon

e

1

Zone

2

Zone

3

Zone

4

Min.

Max.

1020

1500

720

OFF

720

2200*

*High cool jumper settin

g

PIA

B

formula

100

(R

e

q’

d

CFM

−

min. C

FM

)

(Max. CFM

−

min. CFM

)

x

U

s

i

ng e

x

a

m

p

l

e v

a

lue

s

abo

v

e,

fi

nd

PIAB

f

o

r

Zone 1

:

PIA

B

(

1

02

0

-

7

2

0

)

= 30

0

=.20

.

.

.

.

..

.

..

.

.

.

..

.

.

.

.

.

...

.

..

.

..

.

(2220 - 720) =150

0

.

.

.

.

..

.

..

.

.

.

..

.

.

.

.

.

.

.

.

.

PIAB Jumper setting

%

.20 x 10

0

20%

.

.

.

.

..

.

.

.

..

.

.

...

.

..

.

Figure 11. Determine PIAB Jumper Settings

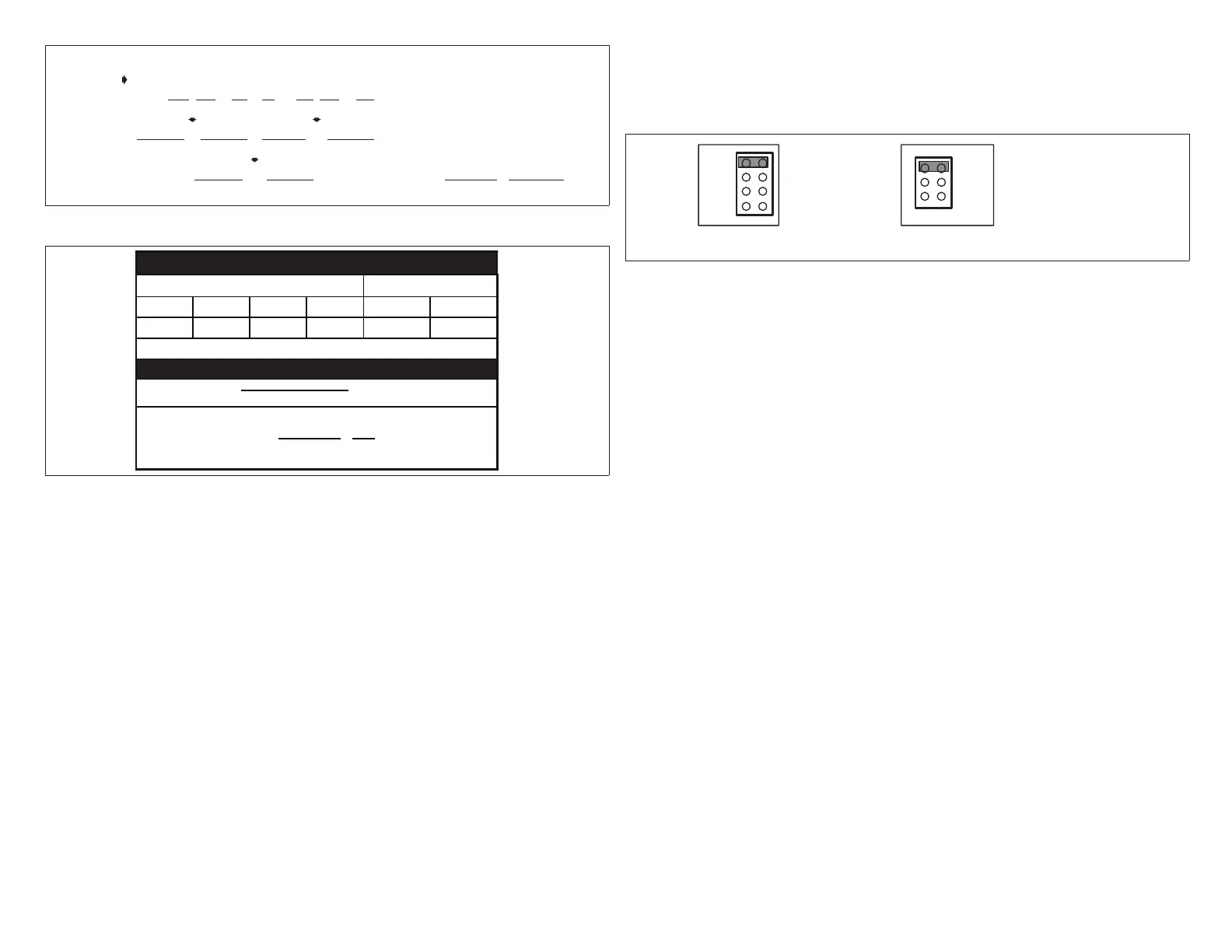

1.10.6. Continuous Air Reduction Jumpers

During continuous fan mode without either a heating or cooling demand, the blower

runs at the total percentage of the CFM jumper settings of the zones calling for

continuous fan (not to exceed 100% of blower capacity). A continuous air reduction

jumper allows the blower speed to be reduced by a percentage during continuous

fan mode.

The selections are 75%, 50%, 25% and 0%. At the factory, the jumper is set on

0%. Set the jumper to the position equal to the amount of continuous air reduction

desired.

NOTE: If the calculations using a reduction percentage indicated a resulting CFM

lower than the blower’s minimum CFM rating, the blower will deliver its

minimum CFM

1.10.7. Heating Air Reduction Jumpers

NOTE: For heat pump applications, ALWAYS set the jumper on 0%. High head

pressures may result if air is reduced during heating mode.

NOTE: For use in warm-climate areas where units have high cooling capacity with

low heat capacity, ALWAYS set the jumper on 0%.

The heating air reduction jumper enables the blower speed, during heating only, to

run at a reduced rate compared to the cooling blower speed.

The selections are 40%, 20% and 0%. Jumpers are set to 0% from the factory.

Set the jumper to the position equal to the amount of heating air reduction desired.

CONTINUOUSHEATING

0%

20%

40%

75%

50%

0%

25%

factory

settings

shown

heating jumper

Must be set on 0%

for heat pump

application

Figure 12. Heating Air Reduction Jumpers

1.10.8. Heat/Cool Staging

Heating/Cooling staging jumpers prevent any rapid staging of the equipment. This

section shows the recommended settings for heating/cooling staging temperatures

andexplainsthetemperaturedifferentialsfordifferentequipmentcongurations.

In the diagrams, sine waves indicate which stage operates during the rise and

fall of discharge air temperature for the different heating/cooling staging jumpers.

Recommended jumper settings are shown in bold type.

1.10.8.1. Heating Staging Temperature Jumper

Heating Staging temperature jumpers are used to set the temperature at which the

secondstageheatingequipmentcomesON.Itsselectionsrangefrom85-130(°F).

Thesettinghasabuilt-indifferentialof20°F(exceptasdescribedwhen140DAS

jumper is used). During operation, when the discharge air temperature falls below

the jumper setpoint, 2nd-stage heating begins. If the discharge air temperature

reaches the differential temperature, 2nd-stage operation ceases and 1st-stage

heating resumes until the temperature again falls below the jumper set point.

NOTE: For SLP98 furnaces only, the furnace ignition control will automatically

adjust ring rate without a second stage heat demand to match the blower

airow (CFM) requested by the Harmony III zoning system.

HeatPump(range:85-110°F,recommended:90).Themaximumdischargeair

temperatureatwhichtheheatpump/electricheatisallowedtorunisxedat135°F.

Loading...

Loading...