57

5.3.6.2. Dual Fuel - SLP98 Variable Capacity and Heat Pump

Job Name:

Indoor Unit Model:

Outdoor Unit Model:

Miscellaneous Items:

9 Install Pressure Switch in the outdoor unit per this instructions (27W13 for R410A or 21J18 for

R22)

9 Install Balance Point Sensor (10Z23) as illustrated in the kit installation instruction. Set to

desired outdoor lock out temperature for HP

9 Install Optional Defrost Tempering Sensor 67M41 (if used) per installation instructions. NOTE:

MUST be located in coil delta plate between furnace and coil

9 Install Discharge Air Sensor per installation instructions. The location of the sensor is CRITICAL

for proper system operation

Indoor Unit Setup:

9 Cut on-board link W914 DEHUM OR HARMONY (R to DS) on furnace IFC control (if not cut,

fuse will blow in Harmony III zoning system control board)

9 W2 connection from Harmony III to SLP98 is optional.

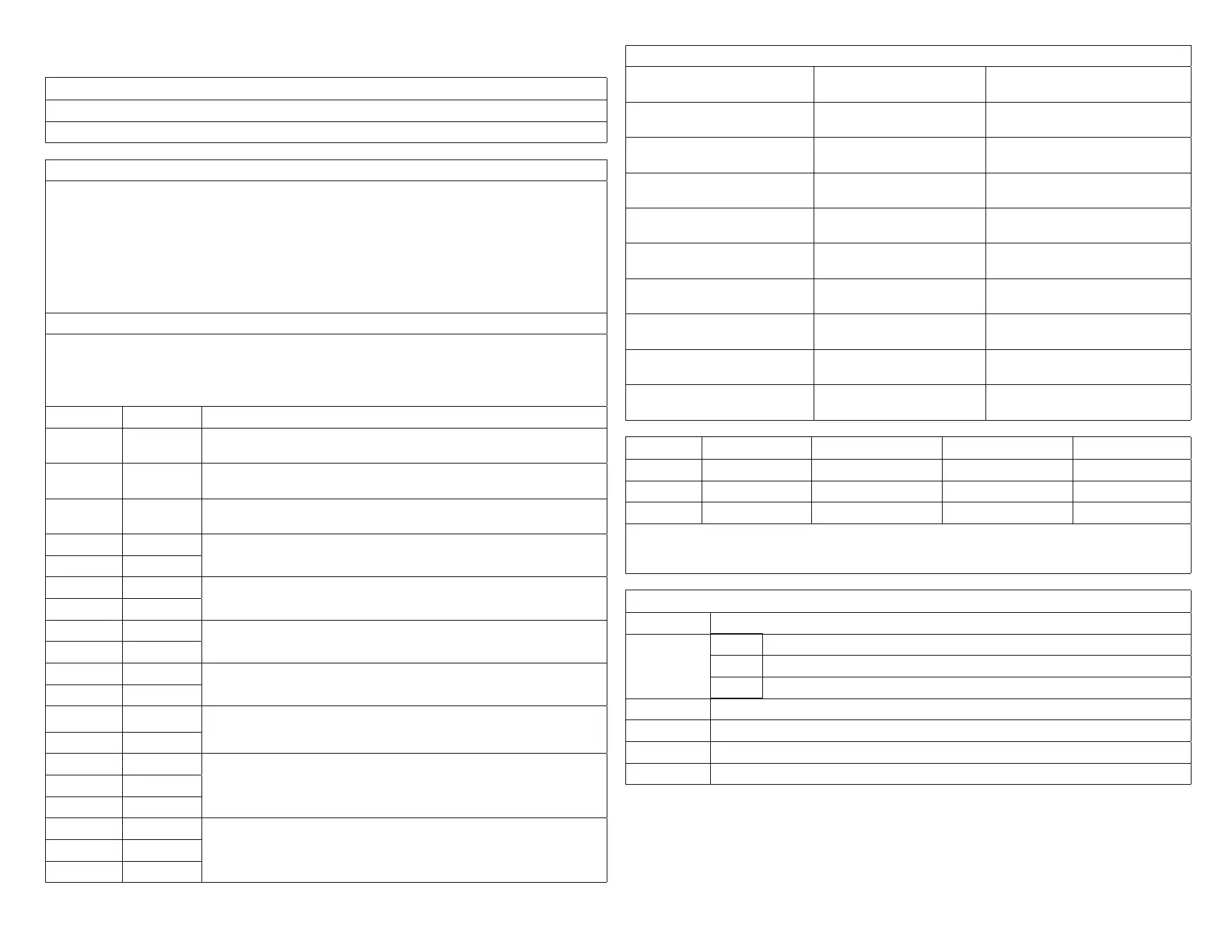

9 DIP switch settings (ON or OFF):

DIPSwitch ON or OFF Condition

1 OFF

DIP switch 1 – leave at factory setting – ignored by Harmony III zoning

system

2 OFF

DIP switch 2 – leave at factory setting – ignored by Harmony III zoning

system

3 OFF

DIP switch 3 – leave at factory setting – ignored by Harmony III zoning

system

4 ON

DIP switches 4 and 5 determine heating blower “off” delay –

recommended 180 seconds

5 ON

6 OFF

DIP switches 6 and 7 – leave at factory setting – ignored by Harmony

III zoning system

7 OFF

8

DIP switches 8 and 9 – cooling blower speed – determines maximum

system CFM – see furnace blower tables

9

10

DIP switches 10 and 11–cooling blower adjust–determines maximum

system CFM – see furnace blower tables

11

12 OFF

DIP switches 12 and 13 – leave at factory setting – ignored by

Harmony III zoning system

13 OFF

14 OFF

DIPswitches14,15,and16–setslowre,minimumcapacity,ring

rate - default setting shown and is recommended starting point.

15 OFF

16 OFF

17 OFF

DIPswitches17,18and19–setshighre,100%capacity,ringrate-

default setting shown and is recommended starting point

18 OFF

19 OFF

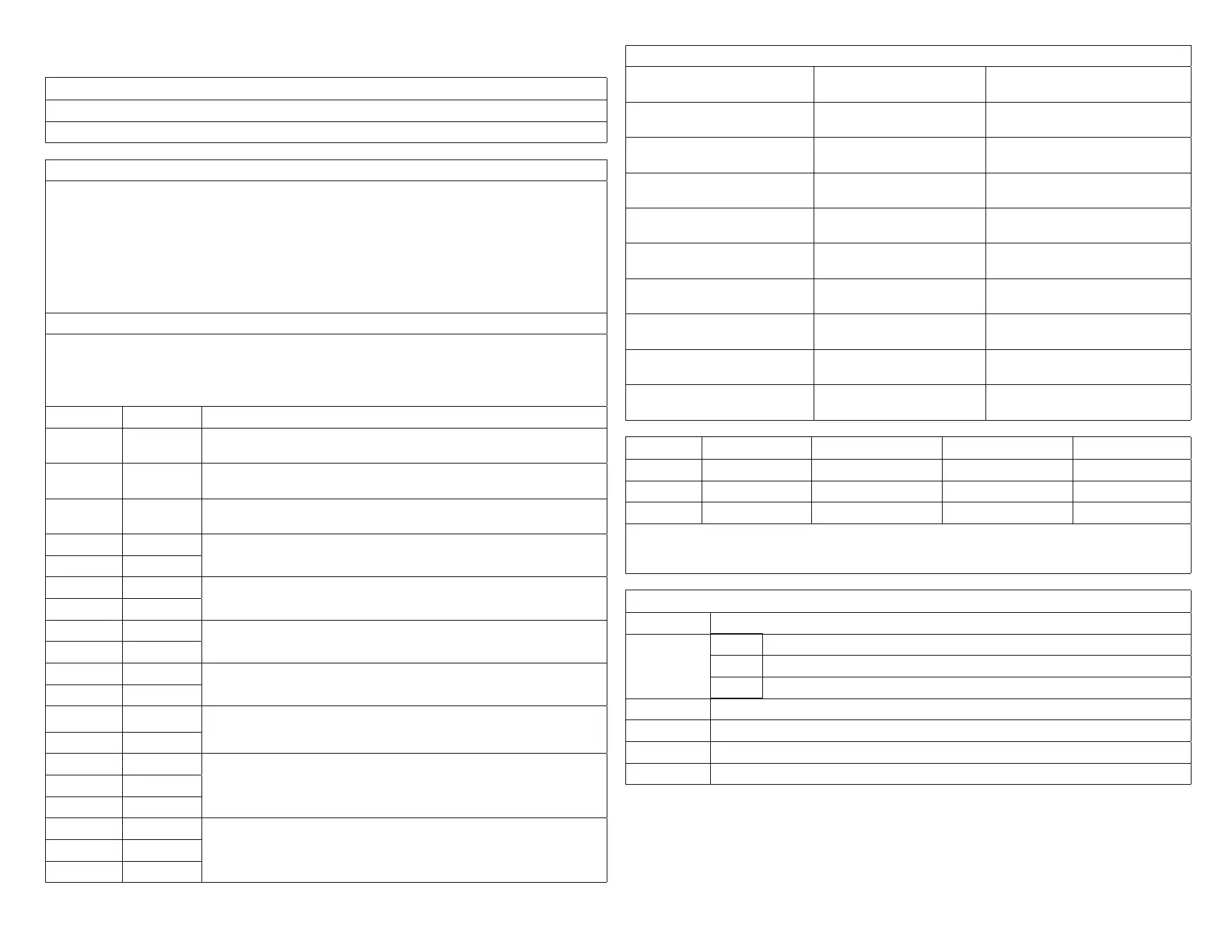

Panel Setup:

9 Heating staging jumper Circle one: 85 90 100 110

120 130

Recommended 120 deg-F

9 Zone 1 PIAB 140F DAS

jumper in place

Circle one: Yes No See “1.10.4. Zone 1 PIAB Jumpers

– 140ºF DAS” on page 10.

9 Cooling staging jumper Circle one: 50 55 60 Select desired discharge air temp

during cooling

9 Cont. Air Reduction jumper Circle one: 0 25 50 75 Percentageairowreductionfor

continuous fan operation

9 Heating Air Reduction

jumper

Circle one: 0 20 40 Percentageairowreductionfor

heating mode

9 SystemConguration

jumpers

Circle one: HP GAS Set to GAS

9 Stages Circle one: 2COOL

1COOL

Set to match condenser, 1 or 2

stage

9 Stages Circle one: 2HP 1HP Ignored for gas heat, non-heat

pump application

9 E-HEAT Stages Circle one: DF 1 2 3 Ignored for gas heat, non-heat

pump application

9 Desired total system CFM

with all zones calling:

Total system CFM per

tables:

Minimum CFM:

9 Zone 1 Name: Desired CFM: PIAB Setting: Actual CFM:

9 Zone 2 Name: Desired CFM: PIAB Setting: Actual CFM:

9 Zone 3 Name: Desired CFM: PIAB Setting: Actual CFM:

9 Zone 4 Name: Desired CFM: PIAB Setting: Actual CFM:

NOTE: All of the above are recommended “starting” positions for the furnace DIP switches and

Harmony III jumpers. Slight variations may be required during system start up and operation

checks.

Field Wiring Checklist

√ Indoor Unit Wiring Completed:

DS on Harmony III to DS on indoor unit connected

C on indoor unit connected to Harmony III transformer C

No connection to Y1 or Y2 on indoor unit.

√ Outdoor Unit Wiring Completed

√ Thermostat and Damper Wiring Completed

√ Discharge Sensor wired to Harmony III zoning system

√ Heat Pump Pressure Switch wired to Harmony III zoning system

Loading...

Loading...