47

Job Name:

Indoor Unit Model:

Outdoor Unit Model:

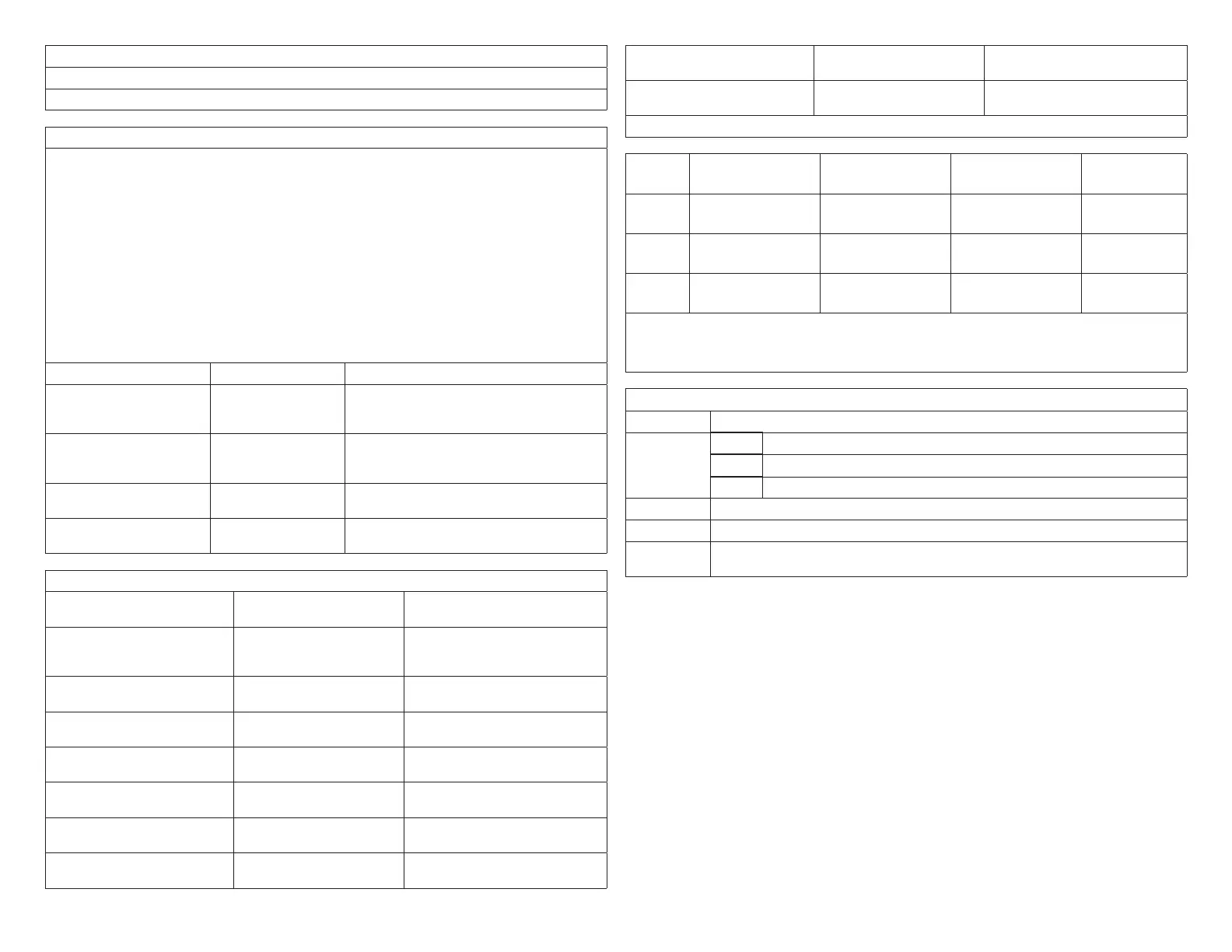

CBX25UHV (all units) and CBX32MV units prior to Revision 06 Indoor Unit Setup:

9 Remove DS to Y1 jumper”

9 No jumper between DS and Y1 on CBX25UHV

9 On the CBX32MV the wire from K20 terminal 4 to BDC3 board JP1 pin 2 must be re-routed to

establish an electrical connection between K20 terminal 4 and terminal G. Cut the wire near

JP1 pin 2.

9 Using the wire still connected to K20 terminal 4, strip the cut end and connect it to terminal G.

Tape the exposed end of the short JP1 pin 2 wire.

9 On the CBX25UHV the blue wire that goes between plug # 2 of the circuit board and one side

of the contacts on the BR relay must be removed and connected to the G pigtail. Tape off end of

wire going to the circuit board jack plug.

9 Remove any factory-installed jumpers between terminal R and W1, W2, or W3. No jumper

between R and W1 or W2 on CBX25UHV.

9 BDC3 control clip jumper settings (CBX25UHV and CBX32MV

Function Settings Condition

COOL

This setting, along with ADJUST setting,

determines maximum system CFM (see

blower tables)

ADJUST

Setting affects both heating and cooling

blower speeds (see blower tables to

determine setting)

HEAT 4

Heating blower speed selection – Ignored by

Harmony III zoning system

DELAY 4

Cooling blower ramping – Ignored by

Harmony III zoning system

Panel Setup:

9 Heating staging jumper Circle one: 85 90 100 110

120 130

Recommended 120 deg-F

9 Zone 1 PIAB 140F DAS

jumper in place

Circle one: Yes No See “1.10.4. Zone 1 PIAB

Jumpers – 140ºF DAS” on page

10.

9 Cooling staging jumper Circle one: 50 55 60 Select desired discharge air temp

during cooling

9 Cont. Air Reduction jumper Circle one: 0 25 50 75 Percentageairowreductionfor

continuous fan operation

9 Heating Air Reduction

jumper

Circle one: 0 20 40 Percentageairowreductionfor

heating mode

9 SystemConguration

jumpers

Circle one: HP GAS Set to GAS

9 Stages Circle one: 2COOL

1COOL

Set to match condenser, 1 or 2

stage

9 Stages Circle one: 2HP 1HP Ignored for gas heat, non-heat

pump application

9 E-HEAT Stages Circle one: DF 1 2 3 Ignored for gas heat, non-heat

pump application

9 Desired total system CFM

with all zones calling:

Total system CFM per

tables:

Minimum CFM:

9 CB unit “minimum” CFM ____________ (determined by unit spec listed below unit blower table)

√Zone1 Name: Desired CFM: PIAB Setting: Actual CFM:

√Zone2 Name: Desired CFM: PIAB Setting: Actual CFM:

√Zone3 Name: Desired CFM: PIAB Setting: Actual CFM:

√Zone4 Name: Desired CFM: PIAB Setting: Actual CFM:

NOTE: All of the above are recommended starting positions for DIP switches and

Harmony III zoning system jumpers. Slight variations may be required

during system start up and operation checks.

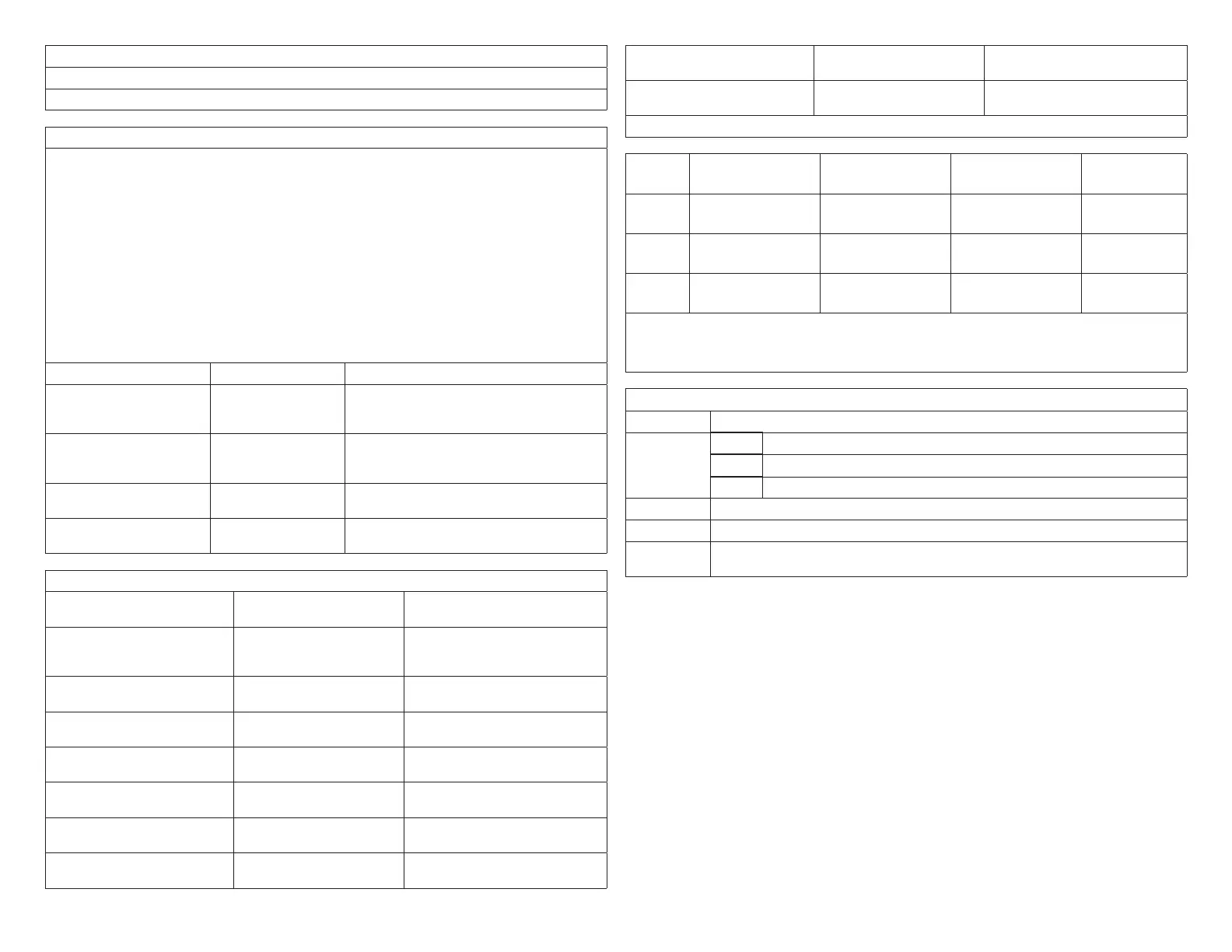

Field Wiring Checklist

√ Indoor Unit Wiring Completed:

DS on Harmony III to DS on indoor unit connected

C on indoor unit connected to Harmony III transformer C

No connection to Y1 or Y2 on indoor unit.

√ Outdoor Unit Wiring Completed

√ Thermostat and Damper Wiring Completed

√ Discharge Sensor wired to Harmony III zoning system and if a hot water coil is used,

the sensor must be located down stream of the hot water coil.

Loading...

Loading...