Troubleshooting and fault elimination

9-5

BA9300SU EN 2.1

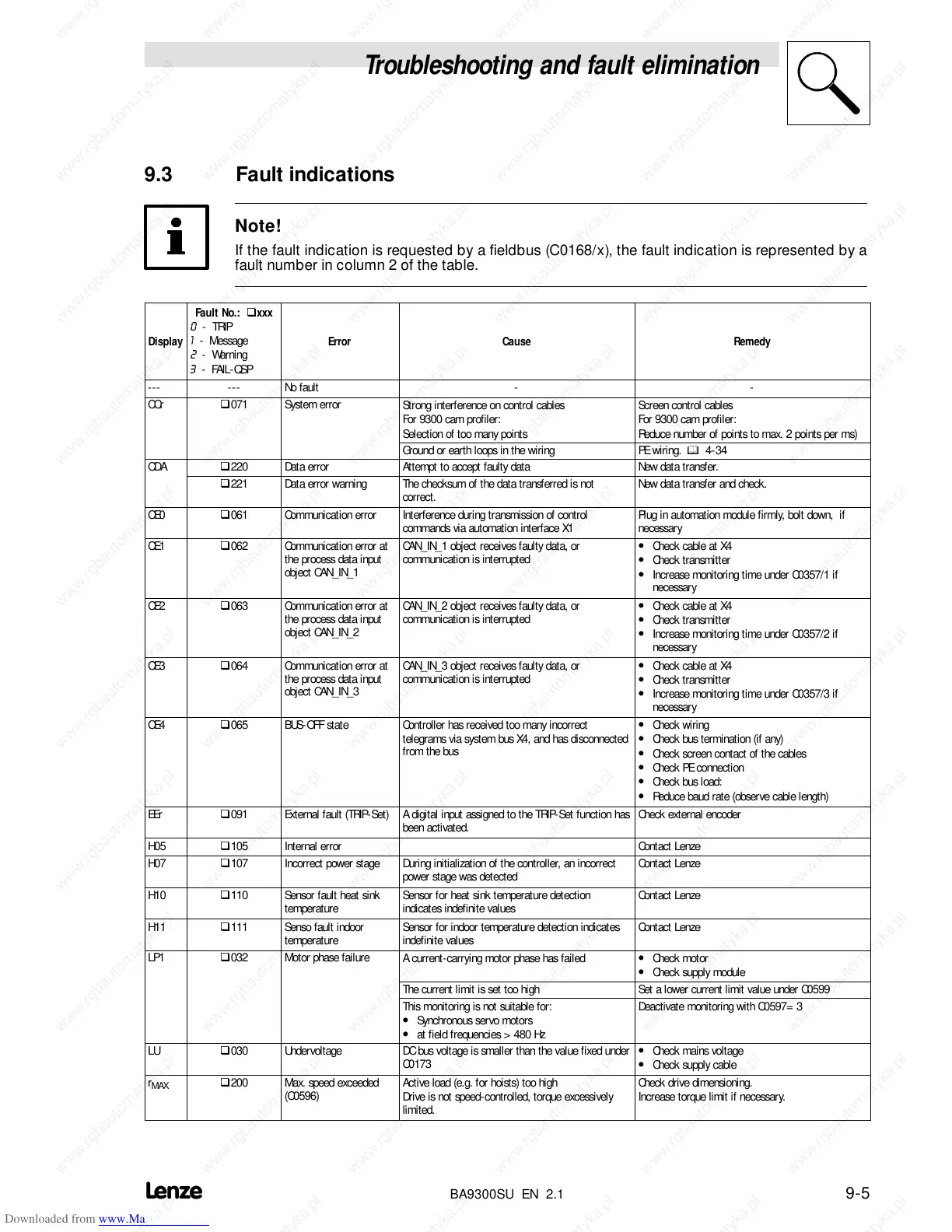

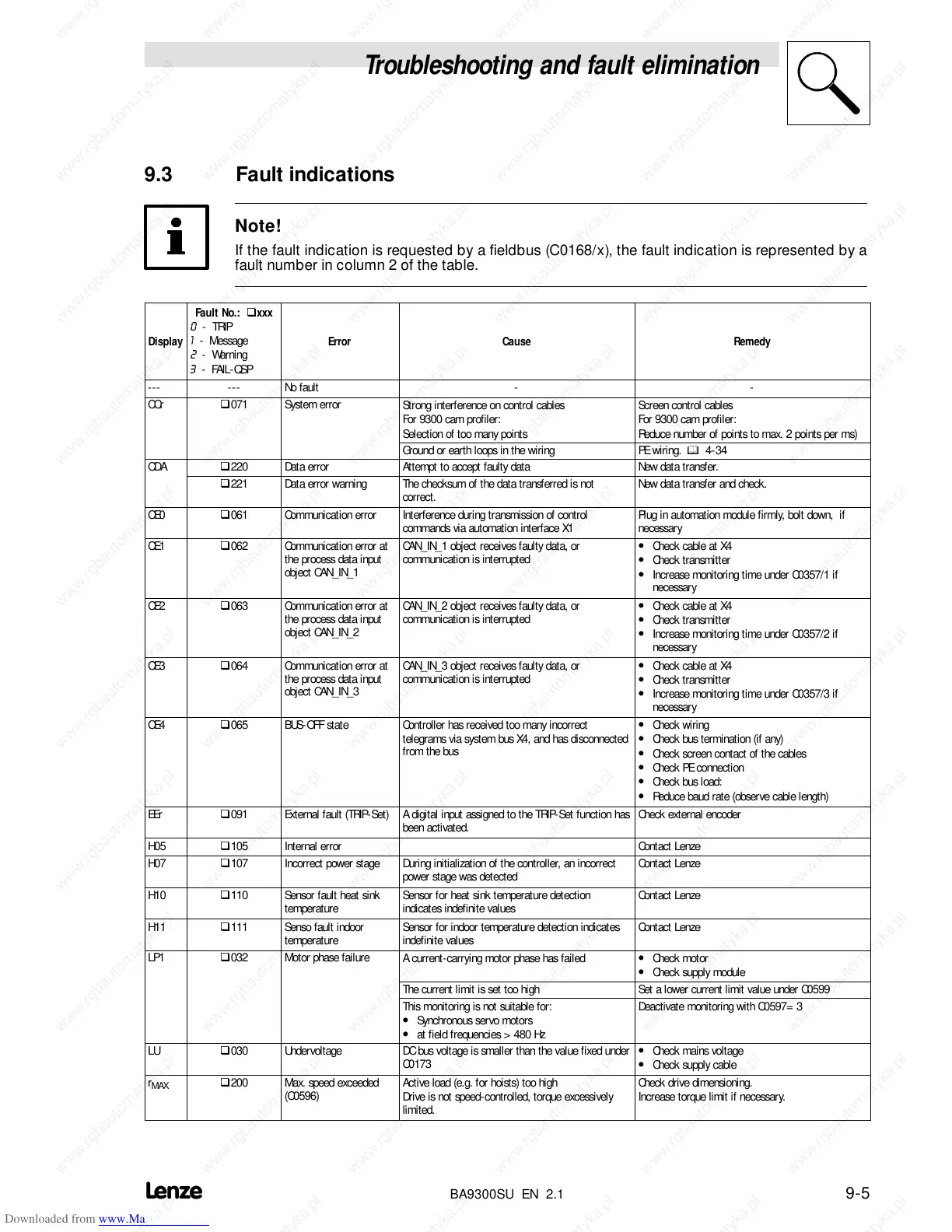

9.3 Fault indications

Note!

If the fault indication is requested by a fieldbus (C0168/x), the fault indication is represented by a

fault number in column 2 of the table.

Display

Fault No.:

q

xxx

-TRIP

- Message

- Warning

-FAIL-QSP

Error Cause Remedy

--- --- No fault - -

CCr

q

071 System error

Strong interference on control cables

For 9300 cam profiler:

Selection of too many points

Screen control cables

For 9300 cam profiler:

Reduce number of points to max. 2 points per ms)

Ground or earth loops in the wiring PE wiring.

^

4-34

CDA

q

220 Data error Attempt to accept faulty data New data transfer.

q

221 Data error warning The checksum of the data transferred is not

correct.

New data transfer and check.

CE0

q

061 Communication error Interference during transmission of control

commands via automation interface X1

Plug in automation module firmly, bolt down, if

necessary

CE1

q

062 Communication error at

the process data input

object CAN_IN_1

CAN_IN_1 object receives faulty data, or

communication is interrupted

• Check cable at X4

• Check transmitter

• Increase monitoring time under C0357/1 if

necessary

CE2

q

063 Communication error at

the process data input

object CAN_IN_2

CAN_IN_2 object receives faulty data, or

communication is interrupted

• Check cable at X4

• Check transmitter

• Increase monitoring time under C0357/2 if

necessary

CE3

q

064 Communication error at

the process data input

object CAN_IN_3

CAN_IN_3 object receives faulty data, or

communication is interrupted

• Check cable at X4

• Check transmitter

• Increase monitoring time under C0357/3 if

necessary

CE4

q

065 BUS-OFF state Controller has received too many incorrect

telegrams via system bus X4, and has disconnected

from the bus

• Check wiring

• Check bus termination (if any)

• Check screen contact of the cables

• Check PE connection

• Check bus load:

• Reduce baud rate (observe cable length)

EEr

q

091 External fault (TRIP-Set) A digital input assigned to the TRIP-Set function has

been activated.

Check external encoder

H05

q

105 Internal error Contact Lenze

H07

q

107 Incorrect power stage During initialization of the controller, an incorrect

power stage was detected

Contact Lenze

H10

q

110 Sensor fault heat sink

temperature

Sensor for heat sink temperature detection

indicates indefinite values

Contact Lenze

H11

q

111 Senso fault indoor

temperature

Sensor for indoor temperature detection indicates

indefinite values

Contact Lenze

LP1

q

032 Motor phase failure

A current-carrying motor phase has failed • Check motor

• Check supply module

The current limit is set too high Set a lower current limit value under C0599

This monitoring is not suitable for:

• Synchronous servo motors

• at field frequencies > 480 Hz

Deactivate monitoring with C0597= 3

LU

q

030 Undervoltage DC bus voltage is smaller than the value fixed under

C0173

• Check mains voltage

• Check supply cable

r

MAX

q

200 Max. speed exceeded

(C0596)

Active load (e.g. for hoists) too high

Drive is not speed-controlled, torque excessively

limited.

Check drive dimensioning.

Increase torque limit if necessary.

Loading...

Loading...