Maintenance

Inspection guide

The purpose of this inspection guide is to aid you in identifying the intervals, based on page count, at which

parts must be inspected (for visible physical damage), cleaned, or replaced.

If any unsafe conditions exist, find out how serious the hazard could be and if you can continue before you

correct the hazard.

As you service the machine, check for the following:

• Damaged, missing, or altered parts, especially in the area of the On/O switch and the power supply

• Damaged, missing, or altered covers, especially in the area of the top cover and the power supply cover

• Possible safety exposure from any non-Lexmark attachments

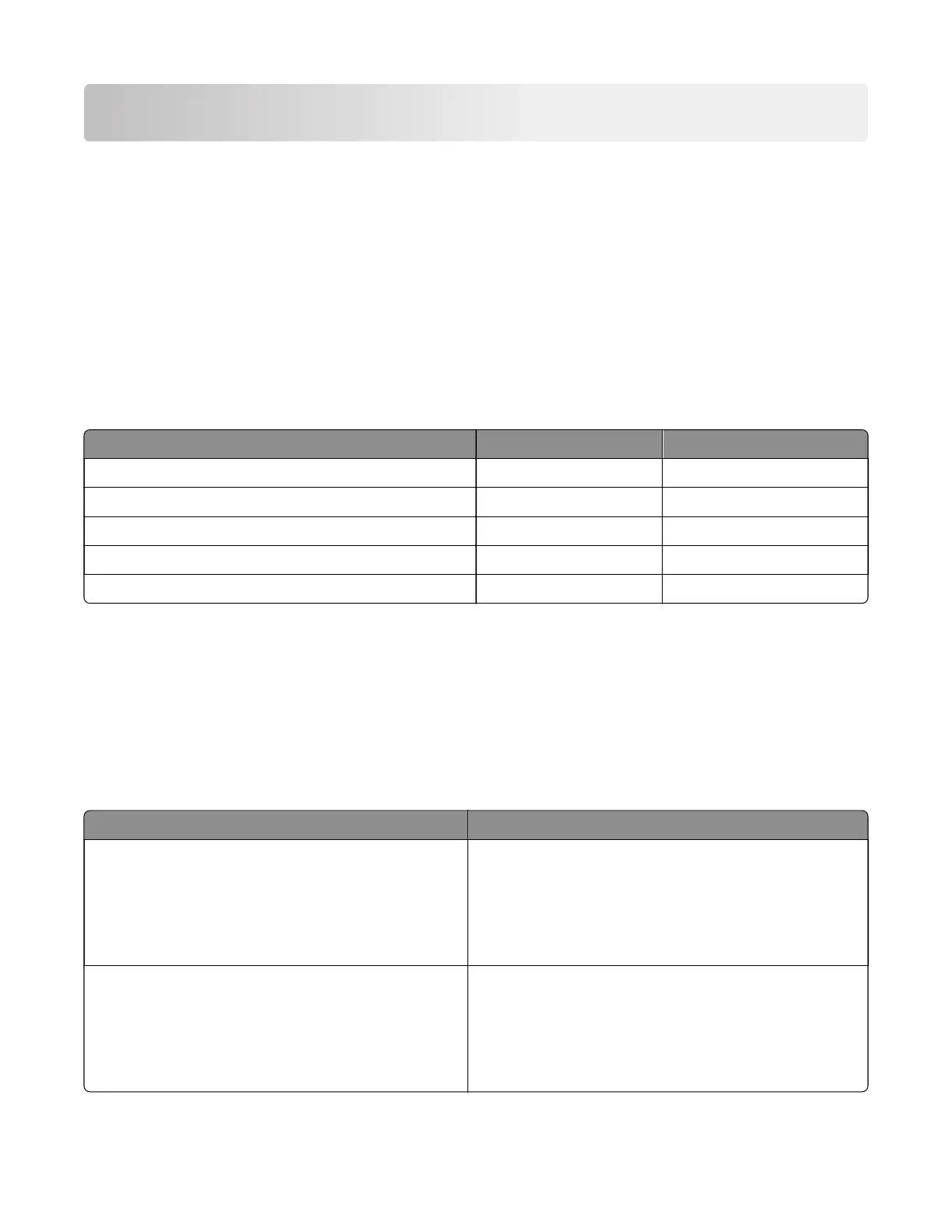

Use the following table to determine when specified parts should be inspected:

PART EVERY SERVICE CALL EVERY 200K

Fuser Inspect Replace

MPF pick roller and separator pad Inspect Replace

Pick tires Inspect Replace

Separator roller assembly Inspect Replace

Transfer roller Inspect Replace

Scheduled maintenance

The control panel displays an 80.xy error when it reaches 200K page counts. It is necessary to install the

appropriate maintenance kit to maintain the print quality and reliability of the printer. Reset the maintenance

counter after replacing the maintenance kit.

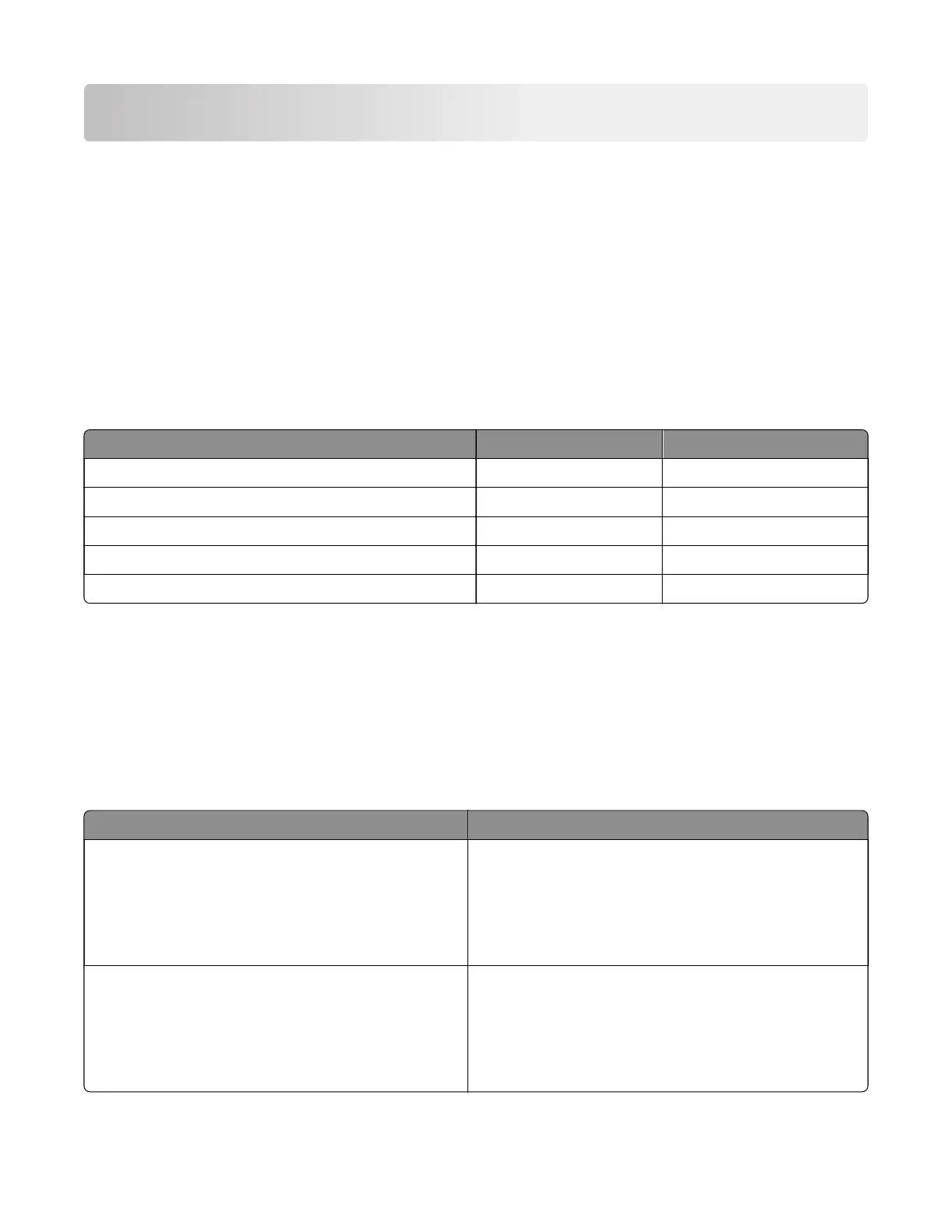

Maintenance kits

Part number and kit Contents

41X1227—Maintenance Kit (100 V)

• 41X1180—Fuser (100 V)

• 41X1197—MPF pick roller and separator pad

• 41X1198—Pick tires

• 41X1212—Separator roller assembly

• 40X8393—Transfer roller

41X1225—Maintenance Kit (110 V)

• 41X1178—Fuser (110 V)

• 41X1197—MPF pick roller and separator pad

• 41X1198—Pick tires

• 41X1212—Separator roller assembly

• 40X8393—Transfer roller

7018

Maintenance

381

Loading...

Loading...