SET-UP AND INSTALLATION 777 OPERATOR’S MANUAL

4-12 Published 10-01-12, Control # 044-05

Install Counterweights

The crane rotating bed must be in-line with carriage while

installing upper counterweight (360° swing is permitted while

assembling counterweights and installing carbody

counterweights).

1. Check that both counterweight limit switches are

properly installed at rear of crane and operational. Test

both limit switches as instructed in Counterweight Limit

Switch Adjustment in Crane Service Manual.

2. Assemble upper counterweights as shown in Figure 4-8,

Views A and B:

a. Lift lower tray onto ground and level it with blocking.

Lift at four lifting lugs on lower tray (Figure 4-8, View

A or B).

NOTE: Rollers on lower tray must face crane.

b. Lift side boxes into position and pin to lower tray

(Figure 4-8, View A-A) — lift at connecting pins

c. Lift remaining side boxes into position and pin to

each other (Figure 4-8, View A-A).

d. On current production cranes using Model 888 or

999 side boxes, be sure to pin steel plates to both

top side boxes (Figure Figure 4-8, View B).

WARNING

Tipping Crane Hazard!

Prevent crane from tipping while assembling

counterweights:

• Do not exceed 26 ft (7.9 m) radius.

• Do not lift more than 40,000 lb (18 144 kg). Tipping or

structural damage may occur.

• Install Series-2 counterweight in exact sequence

given in this procedure and shown in Figure 4-9,

View A.

Avoid dropping counterweights during assembly:

• Do not lift lower tray and side boxes as a unit. Lifting

lugs may break.

• Do not lift more than two side boxes at a time. Lifting

lugs may break.

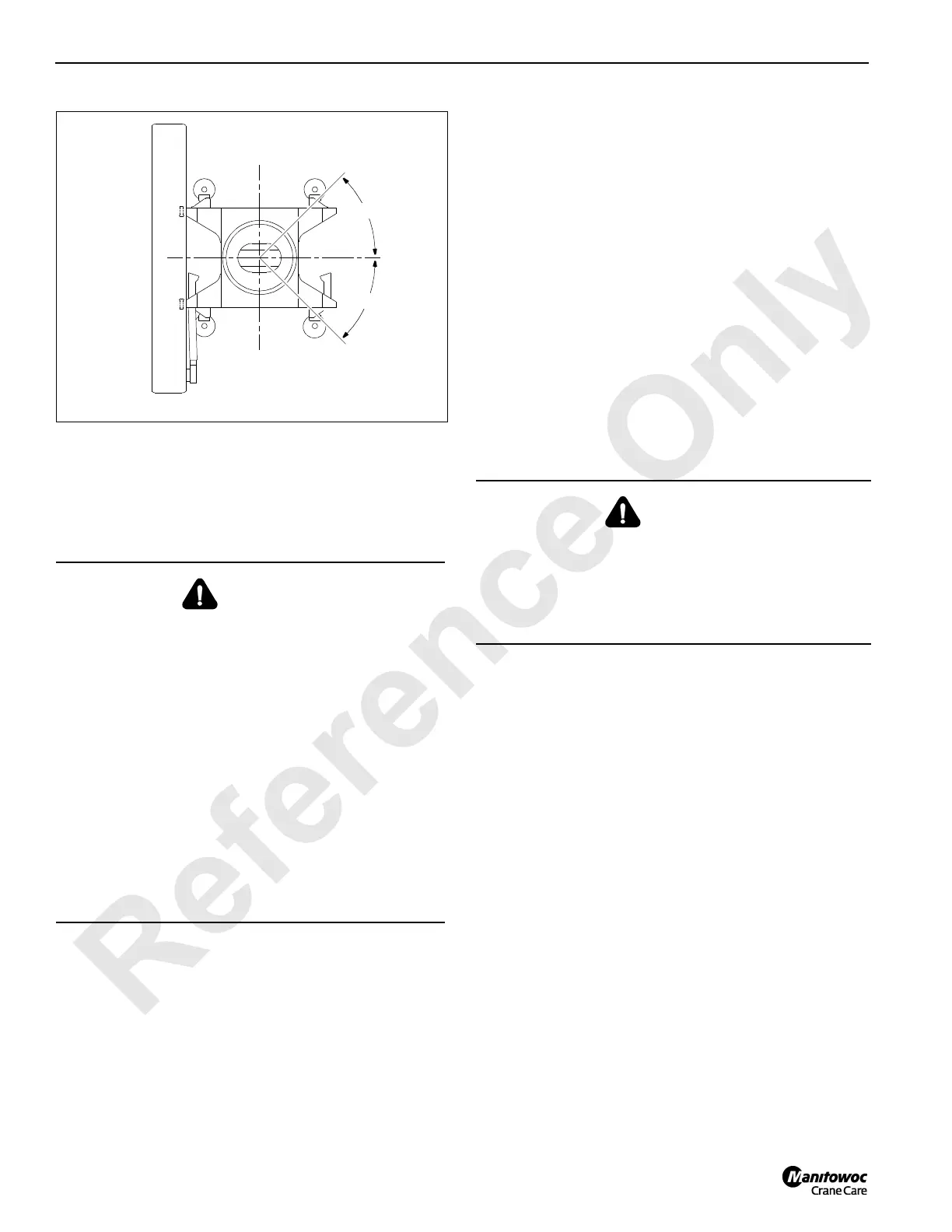

da0102.ai

45°

45°

FIGURE 4-7

WARNING

Tipping Crane Hazard!

Prevent crane from tipping on current production cranes

using Model 888 or 999 side boxes:

• Pin steel plates to both top side boxes as shown in

Figure Figure 4-8, View B.

Loading...

Loading...