SET-UP AND INSTALLATION 777 OPERATOR’S MANUAL

4-80 Published 10-01-12, Control # 044-05

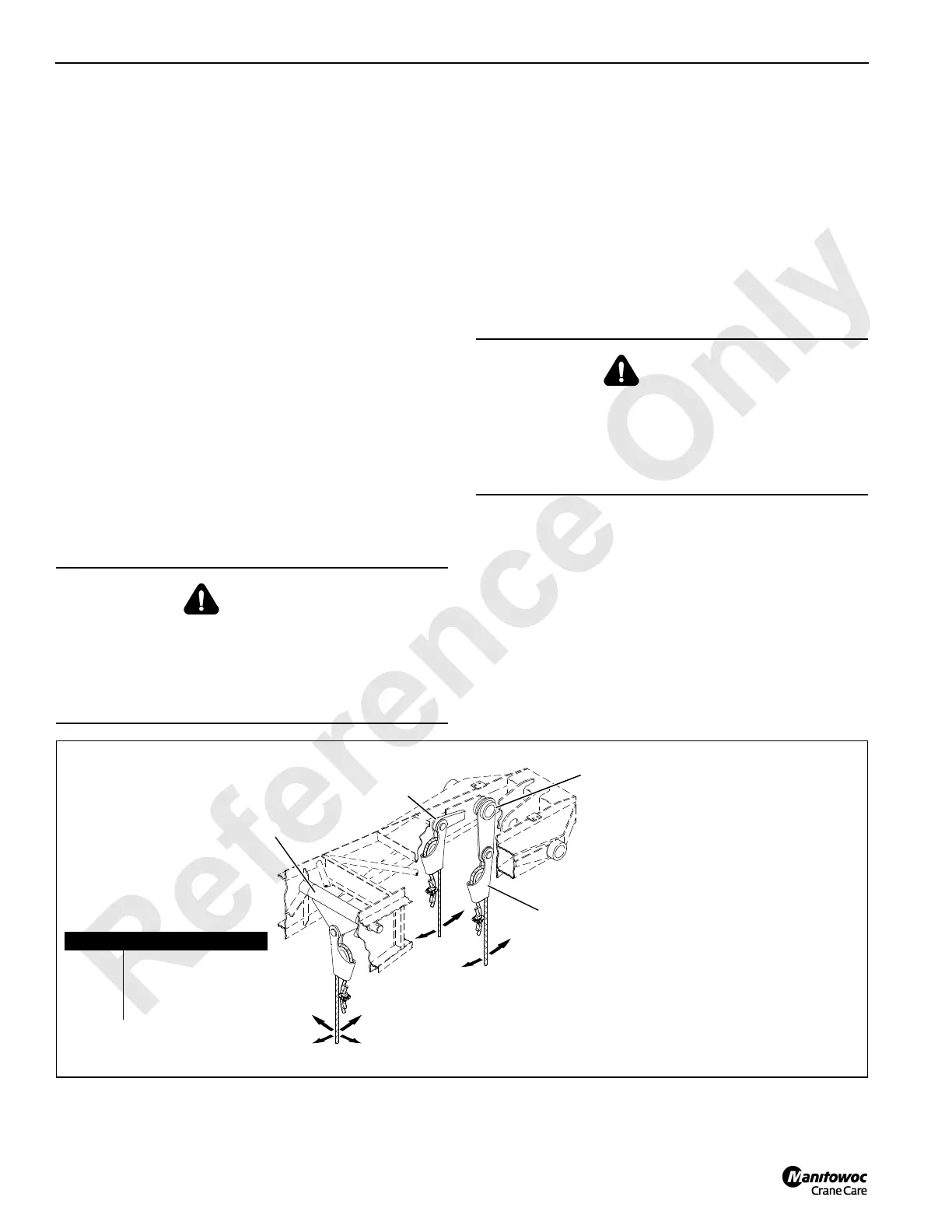

UNIVERSAL ANCHOR JOINT

The dead-end socket and wedge can be anchored to any of

the following locations in the boom and jib point, depending

on the type of operation (see Figure 4-52):

1. Link (if equipped) in boom or jib point for liftcrane

operation.

2. Lug welded inside boom or jib point directly behind

boom or jib point shaft for liftcrane operation.

3. Universal anchor joint located 30 in. (0.8 m) to 72 in. (1.8

m) behind boom or jib point. This location provides

greater separation between the load lines which reduces

twisting of the load. The universal anchor joint is used for

magnet, clamshell, grapple and liftcrane operation

requiring a 2-part load line. For container handling or

rock tray operation, a double hanger universal anchor

joint is used.

NOTE: Movement of the dead-end socket on the link or lug

(1 and 2 above) is in two directions only – forward

and back (see Figure 4-52). Movement of the

dead-end socket on the universal anchor joint (3

above) is in four directions – forward, back and

sideways (see Figure 4-52).

If the anchor link or lug in the boom or jib point has been

used for any duty-cycle work with a 2-part load line, check for

cracks due to side bending loads. Consult with factory for

repair procedure.

If the boom or jib point is not prepared for the universal

anchor joint, the boom or jib top is neither designed for nor

intended for duty-cycle work.

For liftcrane operation requiring 3-parts of load line or

greater, it is necessary to remove the universal anchor joint.

This step will prevent interference of the universal anchor

joint with the wire rope at high boom angles.

For wire rope size and maximum load of universal anchor

joint, see appropriate wire rope chart, capacity chart, or

rigging drawing.

WARNING

Falling Load Hazard!

Do not dead-end a 2-part load line to anchor link or lug in

boom or jib point for magnet, clamshell, grapple or other

operations requiring rapid swing cycles. Sideways motion

may break link or lug causing load to fall.

WARNING

Falling Load Hazard!

Do not operate as liftcrane at high boom angle with

universal anchor joint in place. Interference of wire rope

with universal anchor joint can damage wire rope causing

rope to break and load to fall.

Dead-End

Socket and

Wedge (typical)

Dead-end anchor link (1) and lug (2)

located in or behind lower boom point

provides movement in two directions only.

Forward and back for liftcrane operation

3

1

2

Universal anchor joint (3) located some distance behind lower

boom point, provides movement in four directions. Forward, back

and sideways for magnet, clamshell, grapple, liftcrane and other

operations requiring a 2-part load line (duty-cycle work).

FIGURE 4-52

Item Description

1 Anchor Link

(lower boom point)

2 Anchor Lug

3 Universal Anchor Joint

Loading...

Loading...