Grove Published 07-06-2017, Control # 406-03 6-13

CD5520/YB5520 OPERATOR MANUAL MAINTENANCE

size of the sheave groove. Rough edges, narrow or worn

grooves will cause damage to the wire rope. Replace

any worn or damaged sheaves.

NOTE: As a sheave wears, the groove for the wire rope

becomes smaller. The tracks on the sheave are

caused by the wire rope. Yet, the wire rope will

continue to engage these tracks, for example like a

chain engages a sprocket. As the wire rope turns

and twists on the sheave, the wire rope will move

out of the worn track. This will cause increased

wear on the wire rope.

Grease Fittings

Lubricate all points indicated under the heading Lubrication

Points, page 6-6.

Internal Cable Sheave Lubrication

The lubrication points on the sheaves are not equipped with

grease fittings (zerks) and will require a grease gun adapter

to accomplish the task.

Special Tools:

Nozzle or needle grease gun fitting:

• 6.35 mm (0.25 inch) diameter nozzle grease gun tip

(Grove P/N 955045). Contact Manitowoc Crane Care to

obtain this tip.

• Observation through the sheave case for the extend

sheaves and the hoist mount for retract sheaves.

NOTE: To determine the amount of grease required,

visually inspect the sheaves. From the front of the

boom, look back through the sheave case at the

extend sheaves. From the back of the boom, look

up through the hoist mount at the retract sheaves.

A small amount of grease extrusion around the pin

is adequate.

The extend sheaves are located on the boom tip end of the

extend cylinder, and the retract sheaves are located on the

inside rear of the 2

nd

section. Lubrication is as follows:

1. Extend boom until grease access hole becomes visible

on side of 2

nd

section.

2. Check alignment between the 2

nd

section access hole

and the 3

rd

section access holes. When these holes

become aligned, the end of the extend cable sheave pin

is visible and accessible for lubrication.

3. This boom position also aligns the access holes at the

rear of the 1

st

section for lubrication of the retract

sheaves.

Inner Boom Pad Lubrication

1. With the boom fully retracted, apply grease to the wear

pads on the top of second boom section with a small

paint brush or a grease gun.

2. Extend boom to position the wear pad access holes

directly above the wear pads on the third boom section,

apply grease to the pads using the brush or gun.

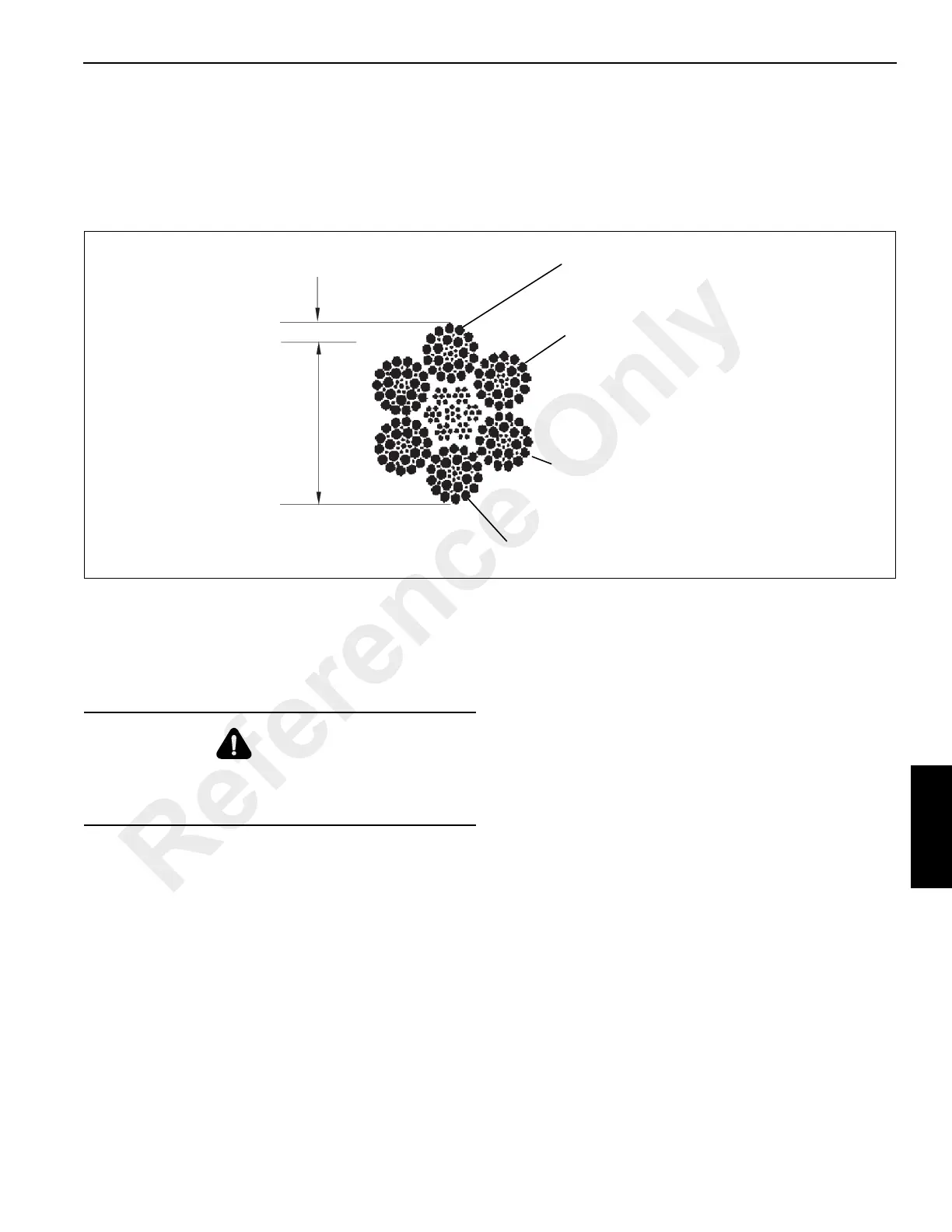

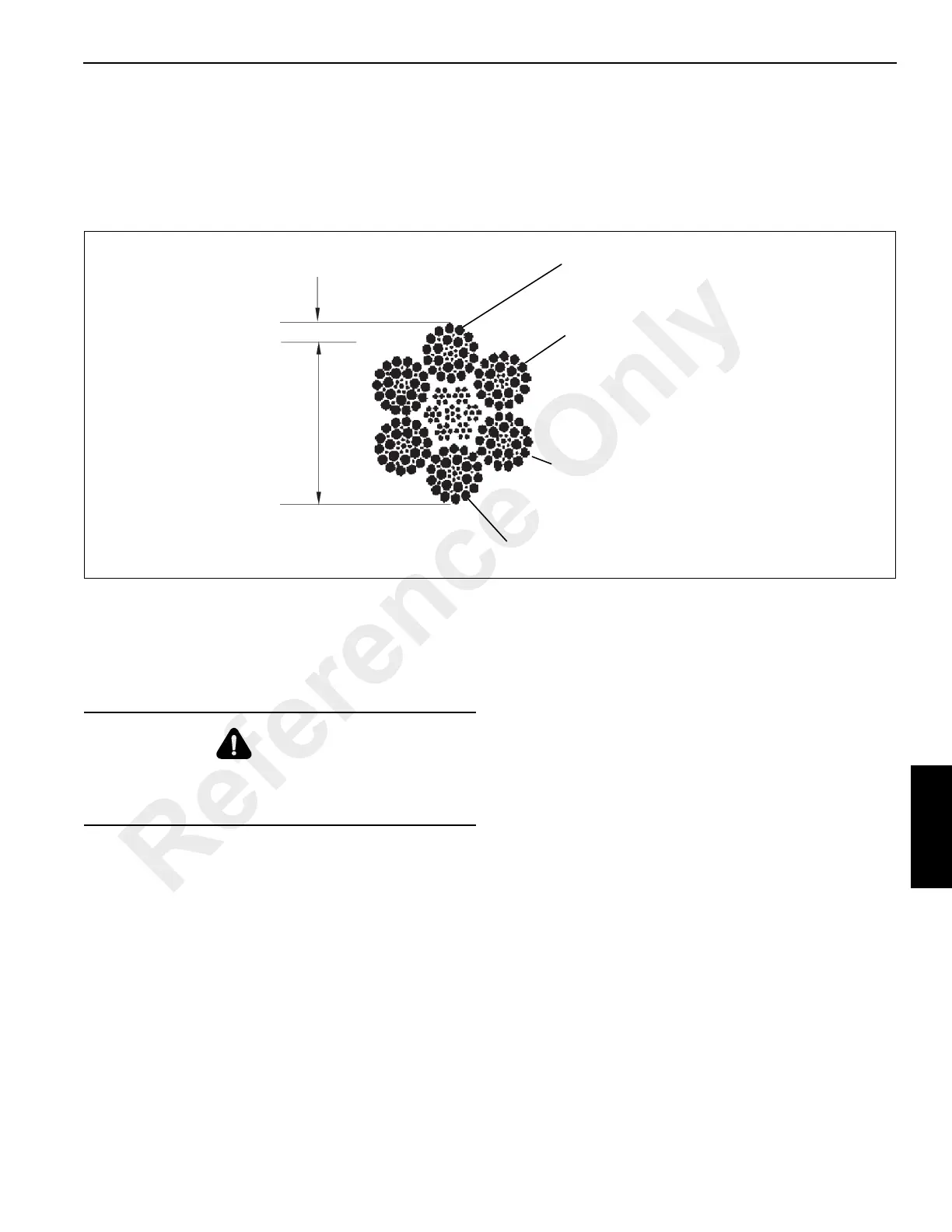

FIGURE 6-23

a0590

Wear greater than 1/3 diameter of

outside individual wires

Reduction from normal diameter of 14

mm (9/16”) of more than 0.8 mm (1/32”)

More than 1 broken wire at a dead-end

connection

6 broken wires in any one lay or 3 broken

wires in one strand in any lay

Kinking, crushing, or distortion of rope

structure

Evidence of heat damage from any

cause

DANGER

Do not, under any circumstances, work at an elevated

height without using proper fall protection as required by

local, state or federal regulations

Reference Only

Loading...

Loading...