MDS-E/EH Series Instruction Manual

1 Installation

5

IB-1501229-F

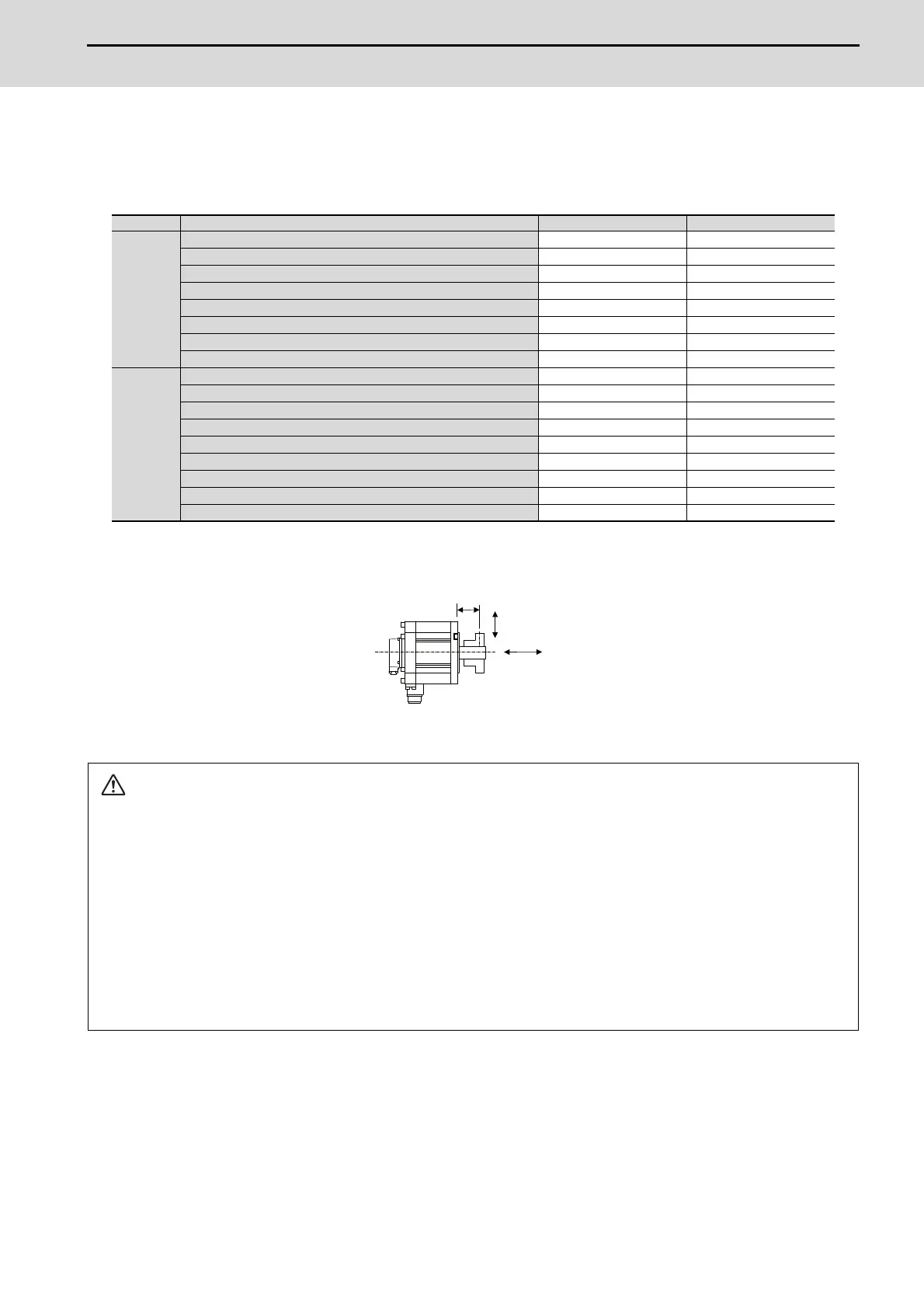

1.1.5 Shaft Characteristics

There is a limit to the load that can be applied on the motor shaft. Make sure that the load applied on the radial direction

and thrust direction, when mounted on the machine, is below the tolerable values given below. These loads may affect

the motor output torque, so consider them when designing the machine.

(Note 1) The tolerable radial load and thrust load in the above table are values applied when each motor is used

independently.

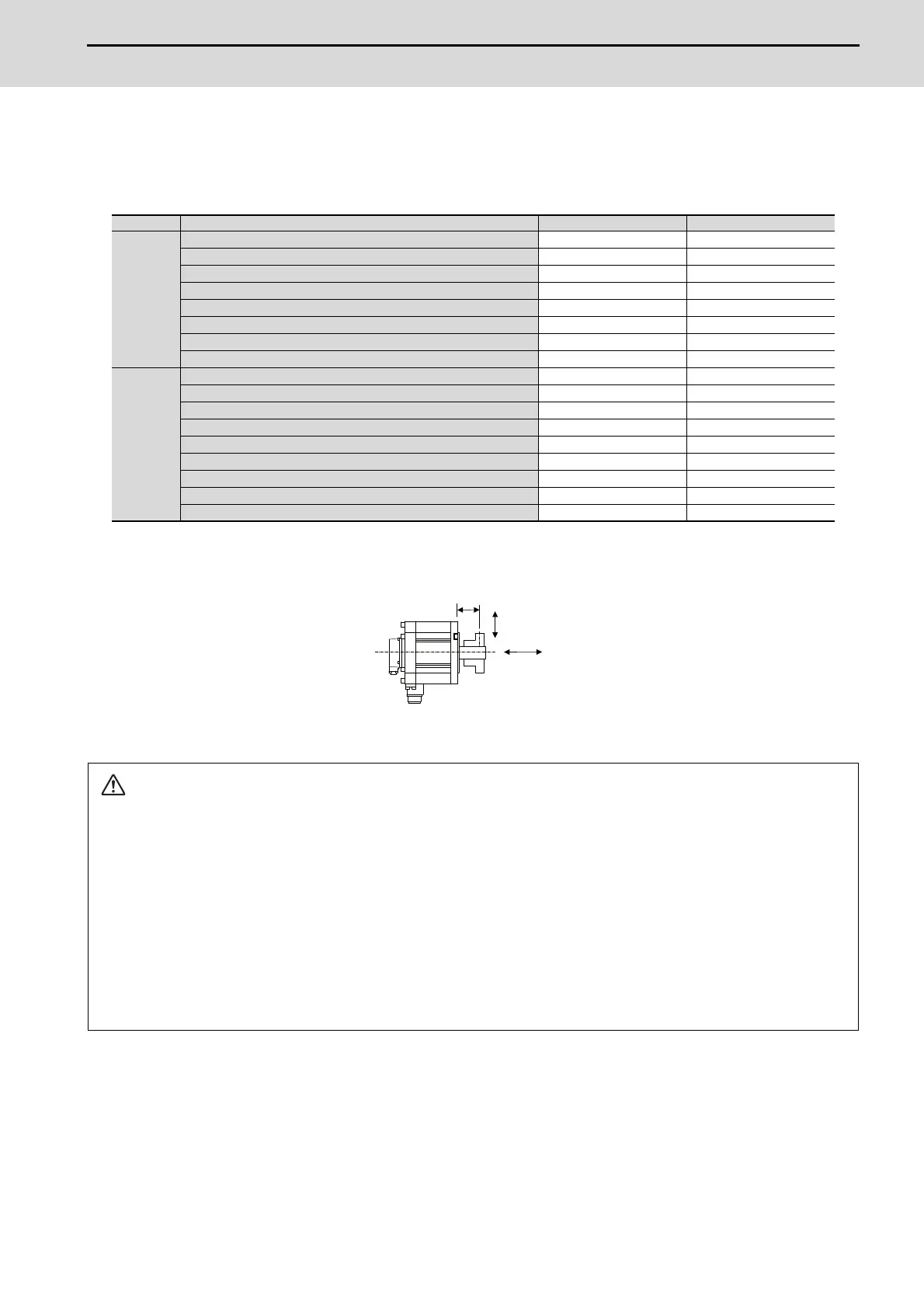

(Note 2) The symbol L in the table refers to the value of L below.

L: Length from flange installation surface to center of load mass [mm]

Series Servo motor Tolerable radial load Tolerable thrust load

200V

series

HG46S, HG56S (Straight shaft) 245N (L=30) 98N

HG96S (Straight shaft) 392N (L=40) 147N

HG75T, 105T (Taper shaft) 245N (L=33) 147N

HG75S, 105S (Straight shaft) 245N (L=33) 147N

HG54T, 104T, 154T, 224T, 123T, 223T, 142T (Taper shaft) 392N (L=58) 490N

HG54S, 104S, 154S, 224S, 123S, 223S, 142S (Straight shaft) 980N (L=55) 490N

HG204S, 354S, 303S, 453S, 703S, 302S (Straight shaft) 2058N (L=79) 980N

HG903S (Straight shaft) 2450N (L=85) 980N

400V

series

HG-H75T, 105T (Taper shaft) 245N (L=33) 147N

HG-H75S, 105S (Straight shaft) 245N (L=33) 147N

HG-H54T, 104T, 154T (Taper shaft) 392N (L=58) 490N

HG-H54S, 104S, 154S (Straight shaft) 980N (L=55) 490N

HG-H204S, 354S, 453S, 703S (Straight shaft) 2058N (L=79) 980N

HG-H903S (Straight shaft) 2450N (L=85) 980N

HG-H1502S (Straight shaft) 3234N (L=140) 1470N

HQ-H903S (Straight shaft) 2500N (L=52.7) 1100N

HQ-H1103S (Straight shaft) 2700N (L=52.7) 1500N

CAUTION

1. Use a flexible coupling when connecting with a ball screw, etc., and keep the shaft core deviation to below the tolerable

radial load of the shaft.

2. When directly installing the gear on the motor shaft, the radial load increases as the diameter of the gear decreases. This

should be carefully considered when designing the machine.

3. When directly installing the pulley on the motor shaft, carefully consider so that the radial load (double the tension)

generated from the timing belt tension is less than the values shown in the table above.

4. In machines where thrust loads such as a worm gear are applied, carefully consider providing separate bearings, etc., on

the machine side so that loads exceeding the tolerable thrust loads are not applied to the motor.

5. Do not apply the loads exceeding the tolerable level. Failure to observe this may lead to the axis or bearing damage.

Radial load

Thrust load

L

Loading...

Loading...