5Maintenance and Inspection

Maintenance and inspection procedures

5-55

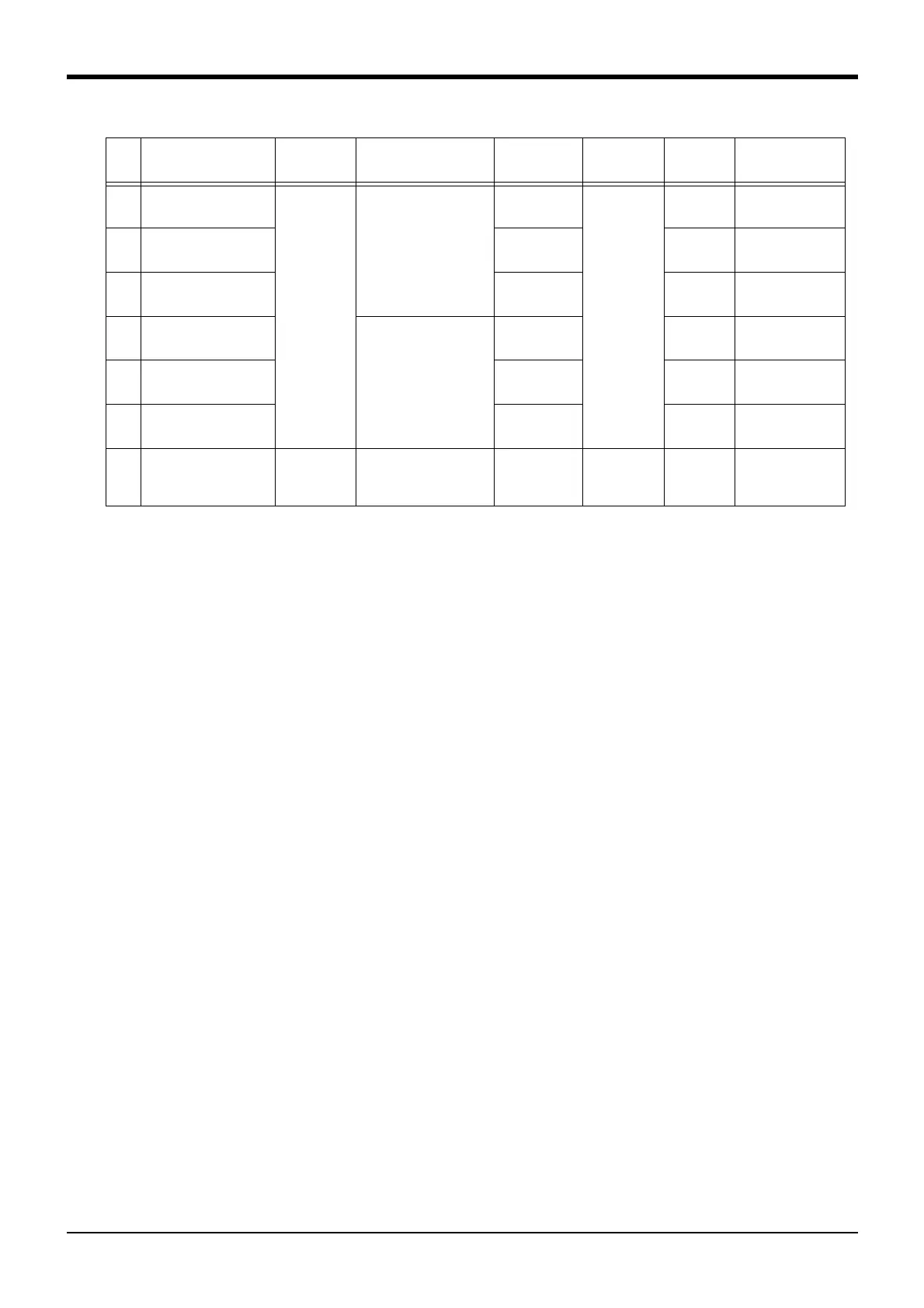

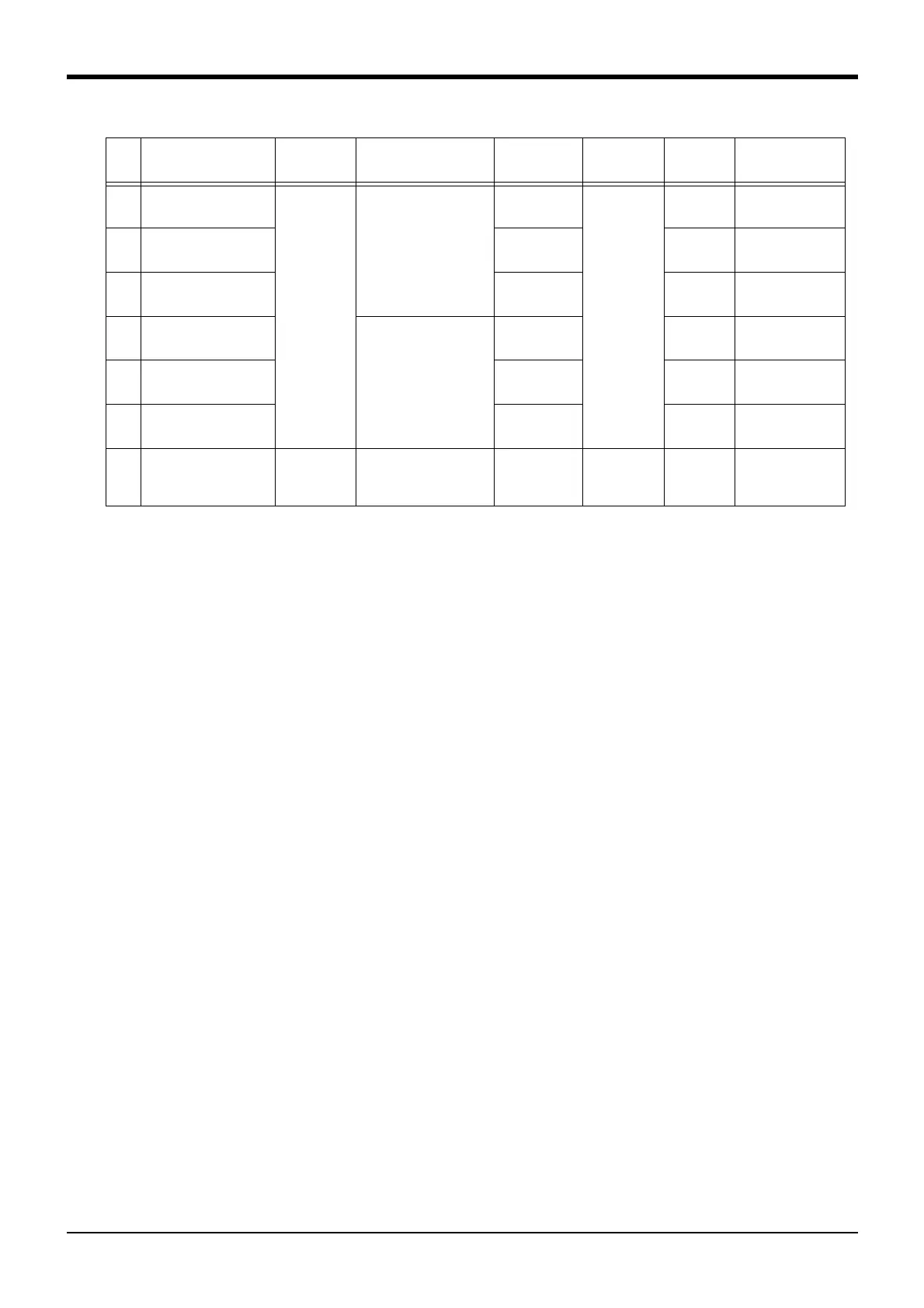

Table 5-5 : Lubrication specifications

The grease nipple position is shown in Fig. 5-9. The lubrication specifications for each place are shown in Table 5-

5.

[Caution]

・ The brands of grease given in Table 5-5 are those filled when the robot is shipped.

・The lubrication time is a cumulative value of the operation at the maximum speed. If the operation has been sus

-

pended, or if the designated speed is slow, the lubrication time can be lengthened in proportion.

(The "Lubrication interval " in Table 5-5 is usually based on the 2-year inspection. 8Hr x 20 days x 24 months =

4000Hr.)

・ Depending on the robot operation state, the lubrication time will fluctuate, so determine the time according to

the state so that the grease does not run out.

・ The numbers in the Table 5-5 correspond to the supply positions in Fig. 5-9.

No. Parts to be lubricated

Oiling

method

Lubrication oil

(maker)

Default charge

amount

Lubrication

interval

Lubrication

amount

Cover to remove

<1>J1 axis reduction gears

Grease nip

-

ple

WA-610

Grease

Harmonic grease SK-1A

(Japan Harmonic

Systems)

70g

4000Hr

2.5 g Shoulder cover (B)

<2> J2 axis reduction gears 30 g 10.5 g

<3> J3 axis reduction gears 30 g 10.5 g

<4>

J4 axis reduction gears

(6-axis type only)

Grease

Harmonic grease SK-1A

(Japan Harmonic

Systems)

17g 5.5 g

<5> J5 axis reduction gears 7g 1.5 g

<6> J6 axis reduction gears 11g 2.5 g Wrist cover (S)

<7> Spring shaft in the base Paint

Shell Alvania Grease

No.2

1g

when wear is

detected

Note1)

Note1) If wear is detected during periodical inspections, apply the grease.

1g Shoulder cover (L)

Loading...

Loading...