18

SCREENGUARD

™

INSTALLATION AND USER MANUAL

INITIAL OPERATION

Preparations

Before activating the filter for the first time, go through the following check-list

carefully (No special training is required to carry out these activities).

Check that the filter is mounted in the correct flow direction.

Check that all nuts and bolts are firmly tighten.

Check that all the command tubes are connected properly and that

all connections are tight (see page 12).

Ensure the filter is well supported an stable.

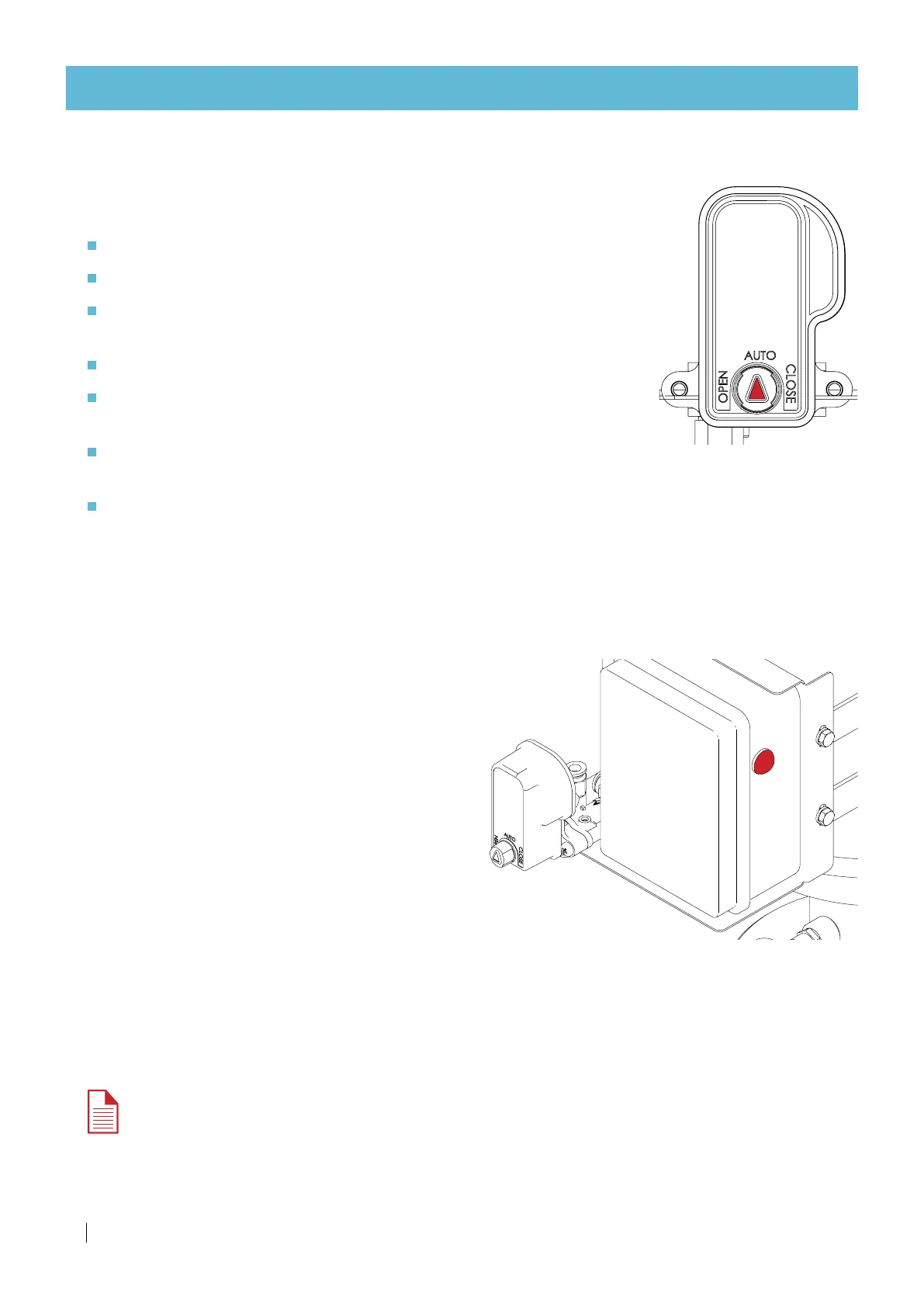

Check that the Aquative operator (solenoid) selector is turned to

the AUTO position.

Make sure that the flush pipe is installed in comformity with the

specifications (see Hydraulic installation, page 14).

Make sure the controller is active by initiating a manual flush (The solenoid should click).

(To initiate a manual flush hold the MANUAL button on the flush controller pressed for 5 seconds or use

the START command in the application.)

First operation

After completing the preparation check-list above, perform the following steps:

1.

Slowly open the isolation valve at the filter inlet.

Water will flow into the filter.

2.

Check for leaks and repair if necessary.

3.

Slowly open the isolation valve at the outlet of

the filter.

4.

Ensure the flow through the filter does not exceed

the filter's maximum flow rate (see page 6).

5.

Start a manual flushing cycle.

(To initiate a manual flush hold the MANUAL button

on the flush controller pressed for 5 seconds or use

the START command in the application.)

6.

Check the upstream pressure

during the flushing cycle

,

it should not drop below 2.0 bar (30 PSI).

8.

Perform 2 additional consecutive manual flushing cycles to evacuate air from the system.

9.

Monitor the upstream pressure

during the flushing cycles

,

it should not drop below 2.0 bar (30 PSI). If this cannot be ensured, consult Netafim™.

NOTE

The filter flushes in two, separate consecutive flushing cycles with a few seconds pause between

them (During the pause the filter does not flush).