6

SCREENGUARD

™

INSTALLATION AND USER MANUAL

DESCRIPTION

Automatic horizontal screen filter selection

Netafim™ offers a selection of ScreenGuard™ automatic, horizontal screen filters to fit any filtration requirement:

NOTE

All horizontal filter models are available with BSTD, ANSI, ISO10 or ISO16 flanges.

All filter models are available with 100, 130 or 200 micron (150, 115 or 80 mesh) filtration grade.

(Other filtration grades are available upon request).

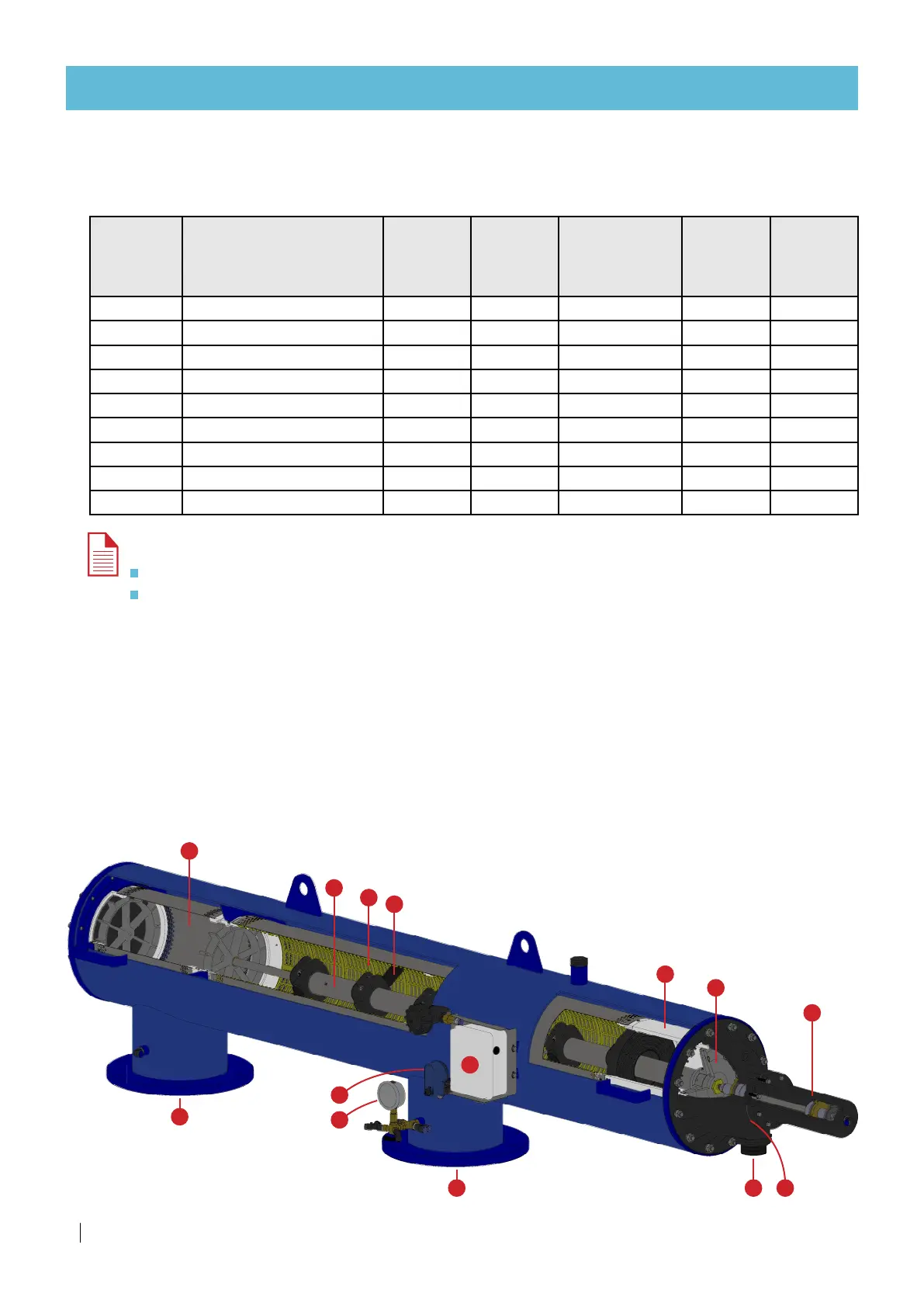

Components and structure

A ScreenGuard™ automatic horizontal screen filter is comprised of the following components:

1.

Inlet

2.

Outlet

3.

Hydraulic piston

4.

Hydraulic flushing turbine chamber

5.

Hydraulic flushing turbine

6.

Fine screen assembly

7.

Strainer

8.

Flush controller

9.

Aquative operator (solenoid)

10.

Suction assembly

11.

Suction nozzle

12.

Pressure gauge

13.

Drain port

14.

Flushing valve

1

2

3

4

5

6

7

8

9

11

10

12

1413

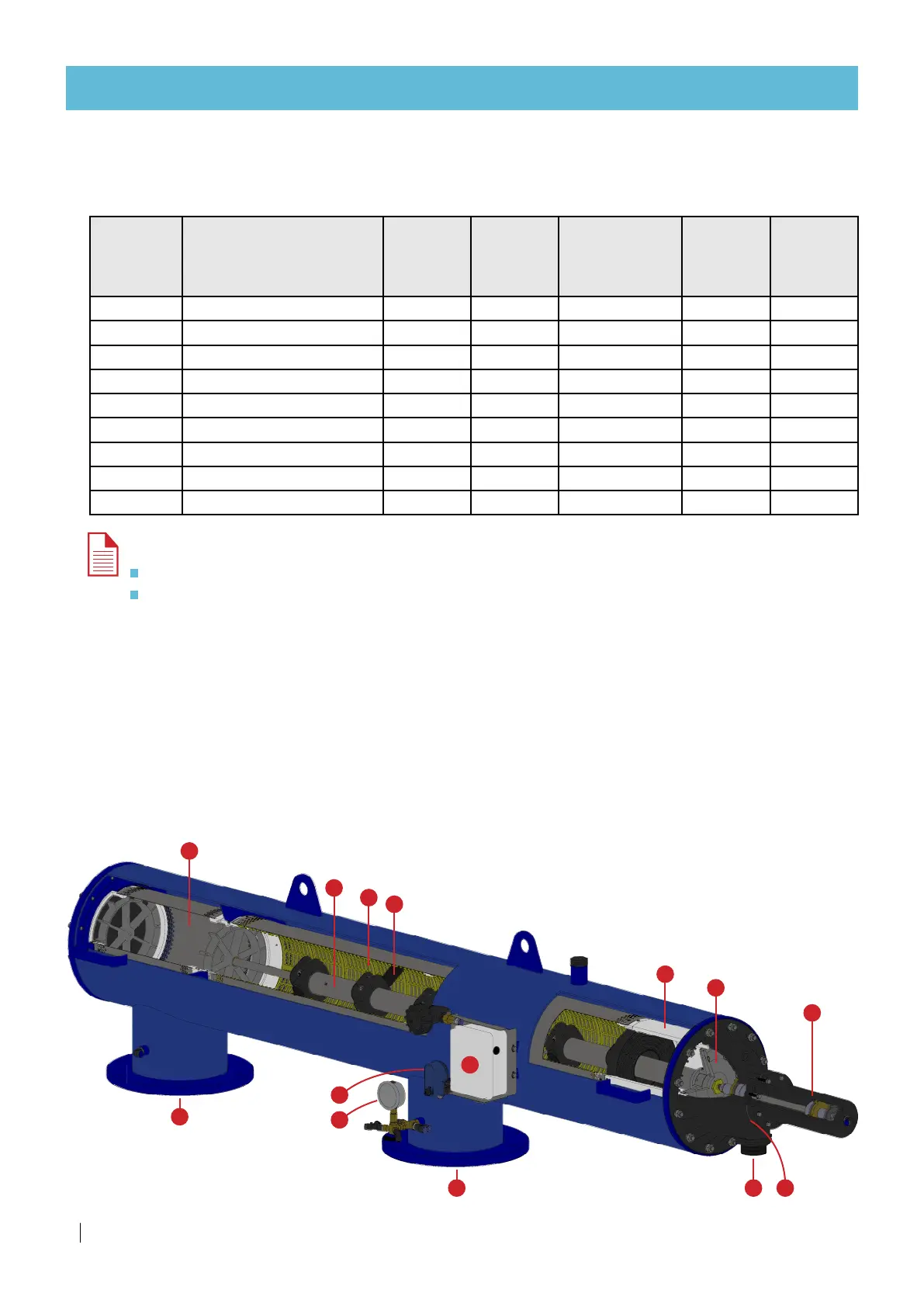

Model Description

Filtration

area (cm

2

)

Max.

Operating

pressure

(bar/PSI)

Max.

recommended

flow rate (m

3

/h)

Min.

bacKflush

pressure

(bar/PSI)

BacKflush

flow rate

(m

3

/h)

SG H 4" F 4" flanged 5,300 10/150 100 2/30 24

SG H 4" JF 4" jumbo, flanged 7,900 10/150 100 2/30 34

SG H 6" F 6" flanged 5,300 10/150 150 2/30 24

SG H 6" JF 6" jumbo, flanged 7,900 10/150 150 2/30 34

SG H 8" F 8" flanged 7,900 10/150 250 2/30 34

SG H 10" F 10" flanged 7,900 10/150 300 2/30 34

SG H 210 F

System, 2 units, 10" flanged

15,800 10/150 500 2/30 34

SG H 312 F

System, 3 units, 12" flanged

23,700 10/150 750 2/30 34

SG H 414 F

System, 4 units, 14" flanged

31,600 10/150 1000 2/30 34

Loading...

Loading...