SECTION 4 -- LUBRICATION AND MAINTENANCE

4--31

GENERAL MAINTENANCE

BLEEDING THE FUEL SYSTEM

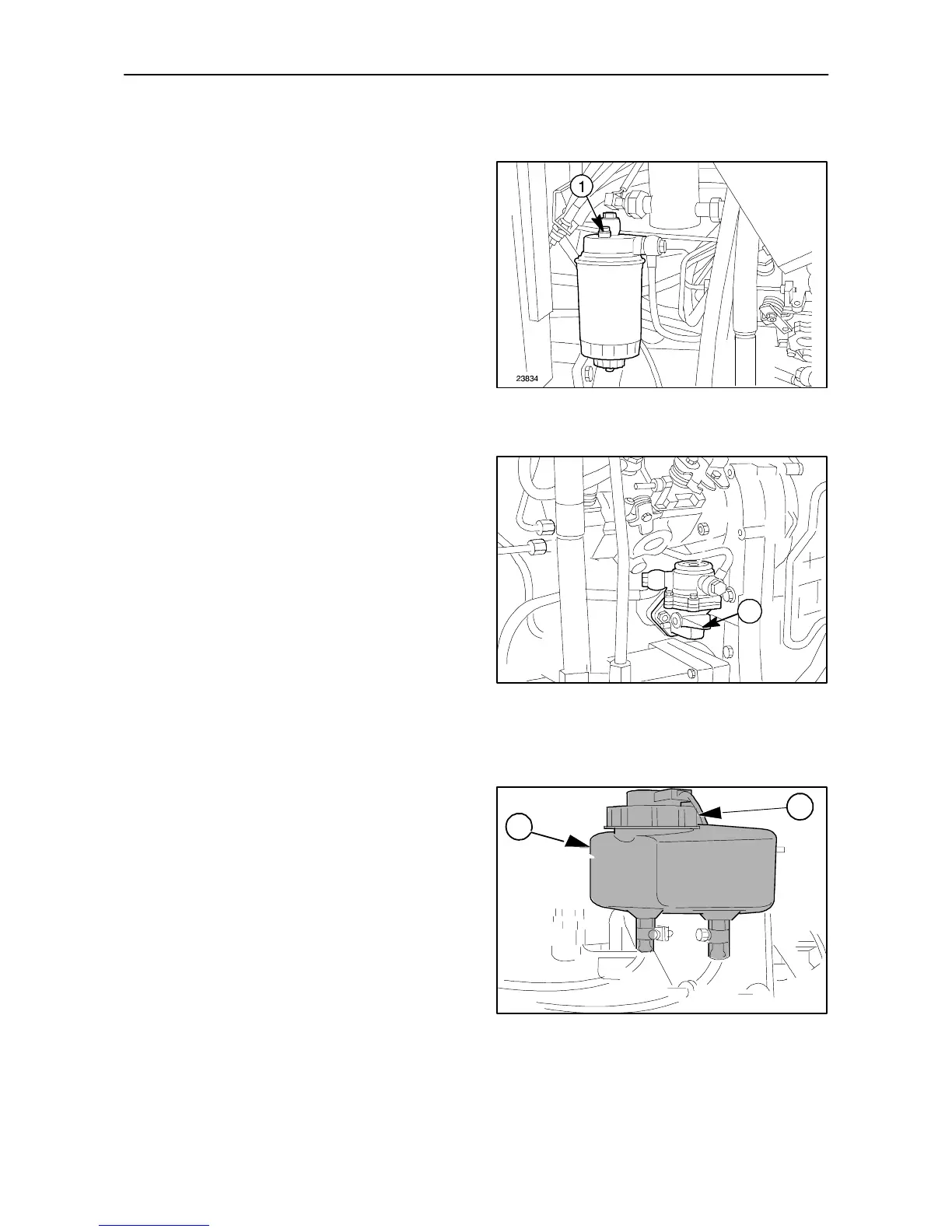

Bleeding procedure -- Figs. 68 and 69

During long periods when the tractor is not used,

when the filter and fuel lines are removed or when

there is no fuel in the tractor, air may enter the fuel

system.

The presence of air makes it difficult to start the

engine and it therefore needs to be bled as follows

when the fuel tank is refilled:

1. Unscrew the bleed plug (1) fig. 68 by

approximately two turns.

2. Actuate lever (1) fig. 69 until fuel without air

bubbles spurts from the bleed hole.

3. Tighten plug (1) fig. 68.

4. After tightening the bleed plug (1) fig. 68, actuate

lever(1)fig69afewtimes.

5. Turn the ignition key to position C, as shown in

Section 2, fig. 18, page 2--11. As soon as the

engine starts, release the key.

NOTE: Y our engine is fitted with a rotary injection

pump, whose internal components must be

protected from rusting if not used for over a month.

Therefore, before stopping the tractor, mix PROT 10

W/M oil with the fuel in the tank in a proportion of

10% and run the engine for approximately half an

hour.

68

23731A

1

69

BLEEDING THE HYDRAULIC BRAKE

SYSTEM

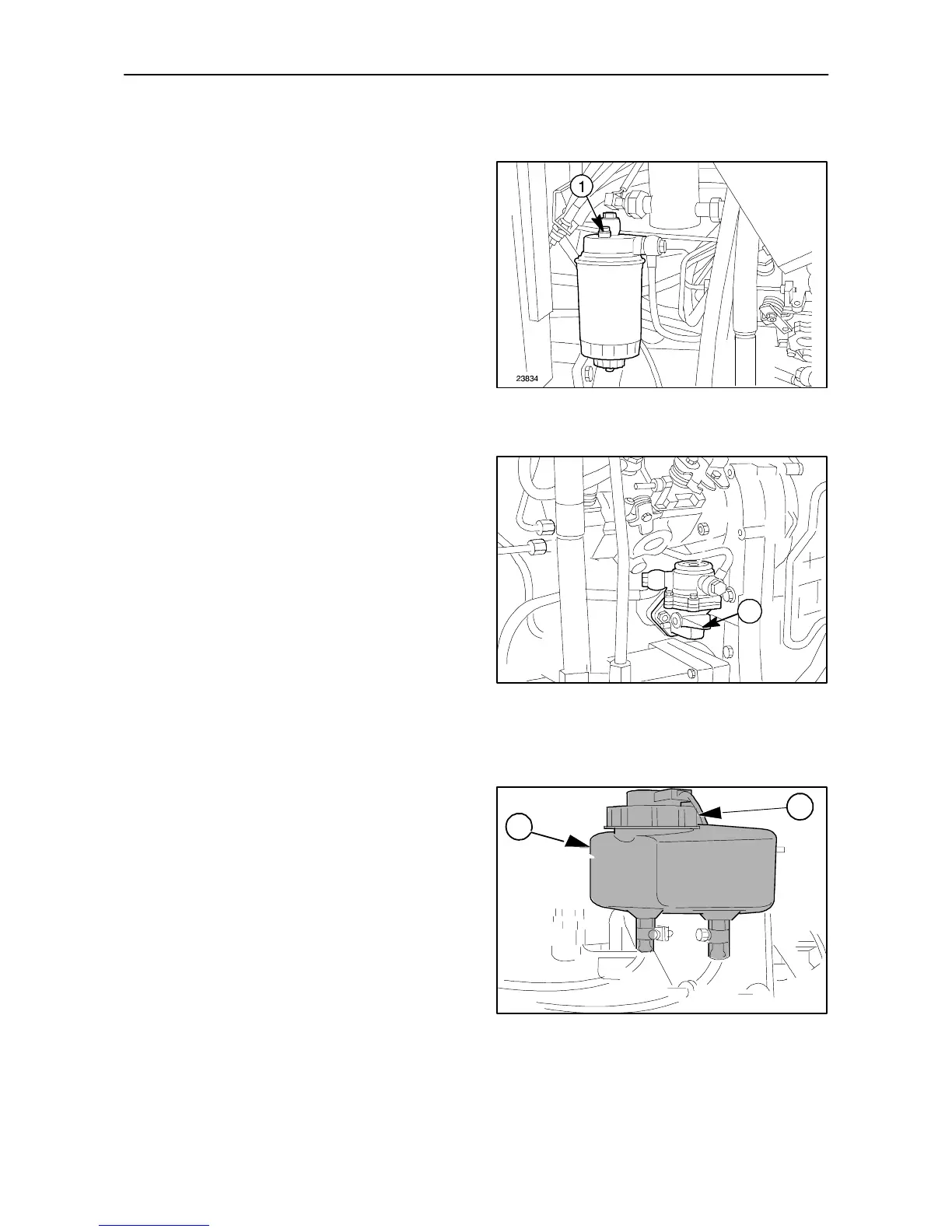

Bleeding procedure -- Figs. 70 to 73

Whenever work is carried out on the front brake hy-

draulic system, the air must be bled from the syst em.

Proceed as follows.

1. Thoroughly clean the external parts of the unit

around the hydraulic fluid tank cap (2) fig. 70 and

the bleed screws (1--2) fig. 71.

2. Make sure that the hydraulic fluid in the tank (1)

70 is maintained up to the full mark both before

and during the bleeding operations.

NOTE: Filter all drained oil before reusing.

1

2

TRE0305A

70

Loading...

Loading...