4 – ENGLISH

INSTALLATION

3

3 INSTALLATION

3.1 PRE-INSTALLATION CHECKS

Before proceeding with the product’s installation, it is necessary

to:

– check the integrity of the supply

– check that all the materials are in good working order and

suited to the intended use

– check that all operating conditions comply with that specied

in the “Product usage limits” paragraph and in the “TECHNI-

CAL SPECIFICATIONS” chapter

– check that the chosen installation location is compatible with

the product’s overall dimensions (see “Figure 2”)

– check that the surface chosen for installing the product is sol-

id and can ensure stable attachment

– make sure that the installation area is not subject to ooding; if

necessary, the product must be installed appropriately raised

above ground level

– check that the space around the product allows safe and easy

access

– check that all electrical cables to be used belong to the type

listed in “Table 1”

– check that the automation has mechanical stops in both the

opening and closing phases.

3.2 PRODUCT USAGE LIMITS

The product must be used exclusively with WG2024, WG3524,

WG4024, WG5024, TOO3024, TOO4524, XME2024 gearmotors

and in accordance with the corresponding usage limits.

3.3 PRODUCT IDENTIFICATION AND OVERALL

DIMENSIONS

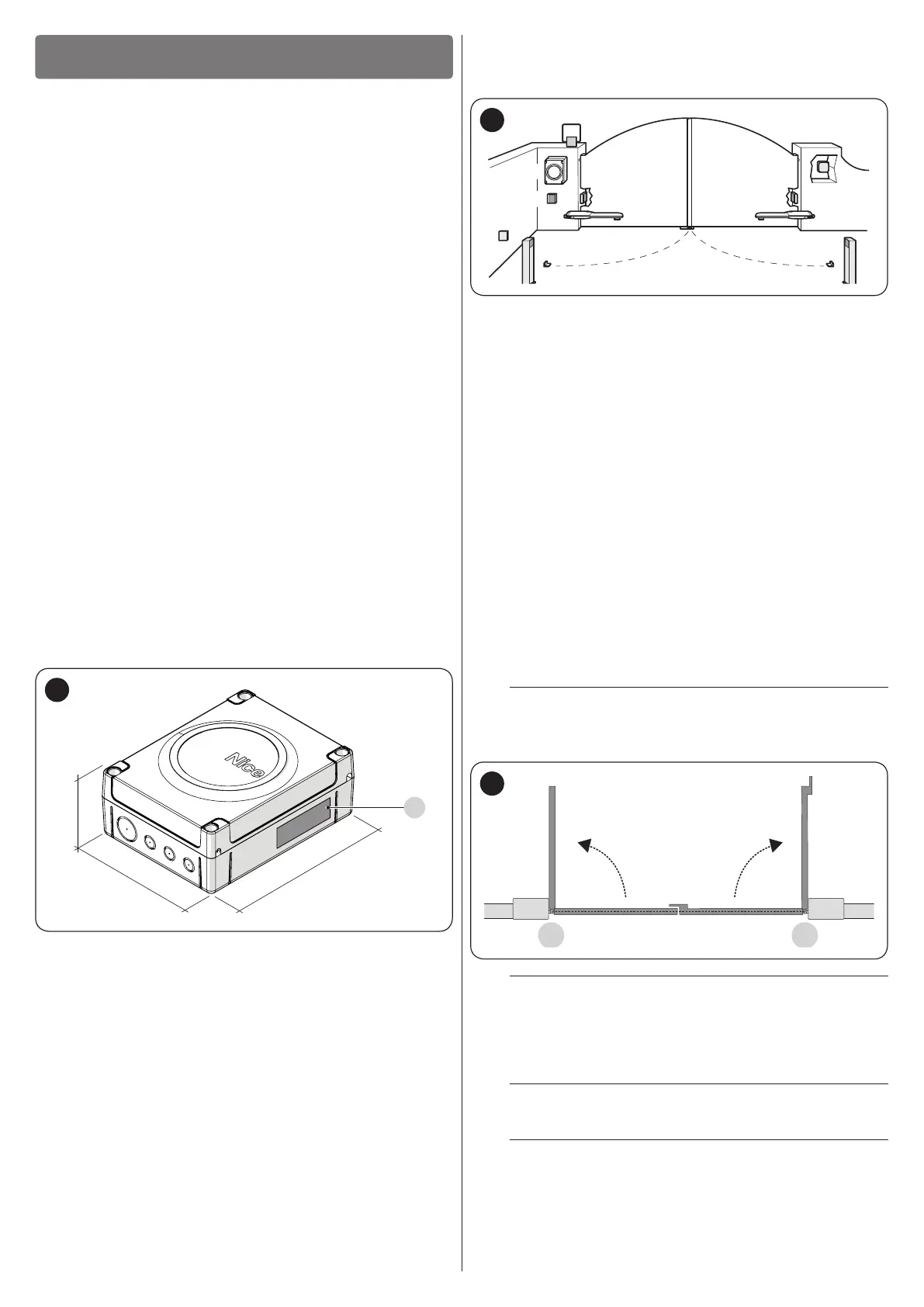

The overall dimensions and label (A) that allow for identifying the

product are shown in “Figure 2”.

232 mm

A

2

3.4 TYPICAL INSTALLATION

“Figure 3” shows an example of an automation system con-

structed using Nice components.

C

F F

D

E E

H

A

G

G

B

3

A WINGO, TOO, SFAB 24 V electro-mechanical actuator

B WINGO, TOO, SFAB 24 V electro-mechanical actuator

C Warning light

D Key selector

E “PHOTO” pair of photocells

F “PHOTO1” pair of photocells

G “PHOTO2” pair of photocells

H Control unit

These above-mentioned components are positioned according

to a typical standard layout.

In particular, bear in mind that:

– for the characteristics and connection of the photocells, con-

sult the specic instructions of the product

– the intervention of the “PHOTO” pair of photocells during the

opening phase has no effect, while it triggers a reversal during

the closing phase

– the intervention of the “PHOTO1” pair of photocells stops the

manoeuvre during both the opening and closing phases

– the intervention of the “PHOTO2” pair of photocells during the

closing phase (connected to the suitably congured AUX in-

put) has no effect, while it triggers a reversal during the open-

ing phase.

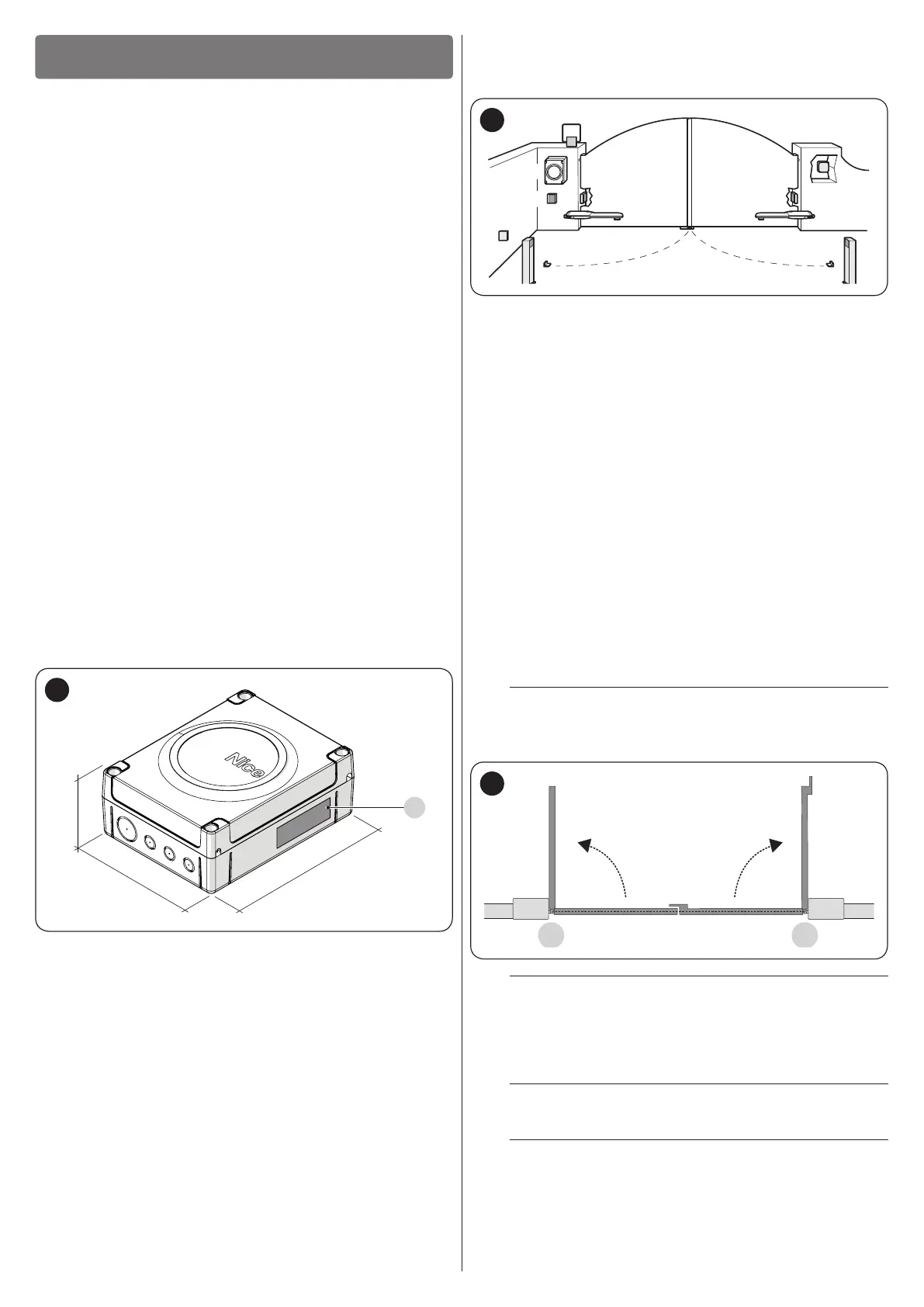

l

Bear in mind that motor M1 is the rst to start for

the closing movement, while motor M2 is the rst to

start for the opening movement (“Figure 4”).

M1 M2

4

a

Before proceeding with the installation, prepare the

electrical cables required for the system by refer-

ring to the “Wiring diagram and description of con-

nections” paragraph and to that specied in the “

TECHNICAL SPECIFICATIONS” chapter.

a

The cables used must be suited to the type of envi-

ronment of the installation site.

a

When laying the ducting for routing the electrical

cables and for the cable entry point into the control

unit housing, check that there are no water depos-

its in the junction wells nor condensate in the con-

nection ducts, as water and damp conditions could

damage the product’s electronic circuits.

Loading...

Loading...