ENGLISH – 13

PROGRAMMING

6

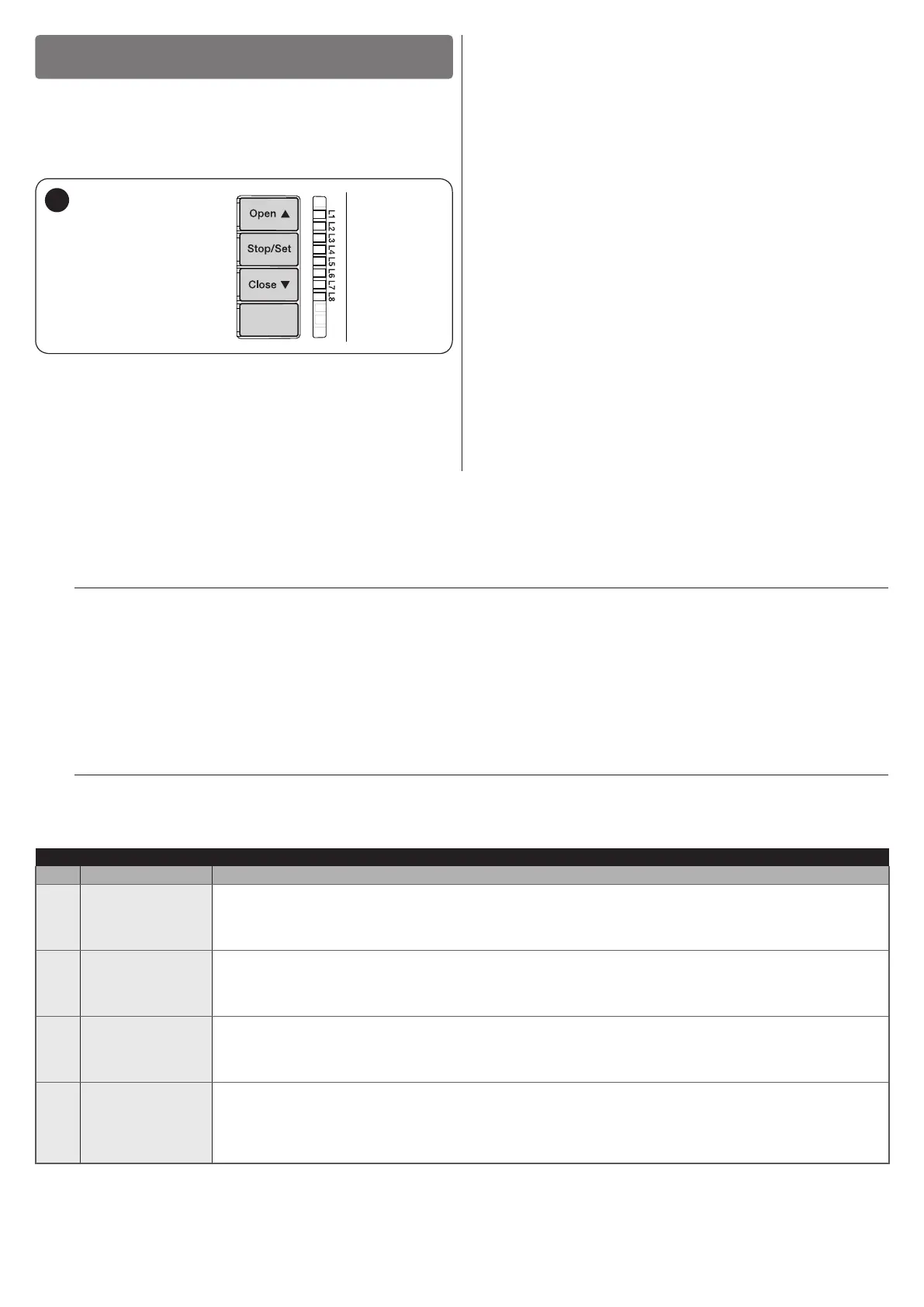

6 PROGRAMMING

There are 3 buttons on the control unit:

f

,

g

and

h

(“Figure 18”) which can be used both to command

the control unit during the testing phase and to programme the

available functions.

The

i

button is not used.

18

The available programmable functions are grouped into two

levels and their operating status is signalled by eight LEDs “L1

... L8” located on the control unit (LED lit = function enabled;

LED off = function disabled).

6.1 USING THE PROGRAMMING BUTTONS

f

Button for commanding the gate opening

Selection button during the programming phase.

g

Button used to stop a manoeuvre

If pressed for more than 5 seconds, it allows for entering

the programming mode.

h

Button for commanding the gate’s closure

Selection button during the programming phase.

i

– Button not used.

6.2 LEVEL 1 PROGRAMMING (ON-OFF)

All the Level 1 functions are factory-set to “OFF” and can be modied at any time. To check the various functions, refer to “Table 6”.

6.2.1 Level 1 programming procedure

m

The user has maximum 10 seconds to press the buttons consecutively during the programming procedure,

after which time the procedure terminates automatically and memorises the changes made up to then.

To perform Level 1 programming:

1. press and hold the

g

button until LED “L1” starts ashing

2. release the

g

button when LED “L1” starts ashing

3. press the

f

or

h

button to move the ashing LED to the LED associated with the function to be modied

4. press the

g

button to change the status of the function:

– short ash = OFF

– long ash = ON

5. wait 10 seconds (maximum time) to exit the programming mode.

l

To set other functions to “ON” or “OFF”, while the procedure is running, repeat points 2 and 3 during the phase

itself.

Table 6

LEVEL 1 FUNCTIONS (ON-OFF)

LED Function Description

L1 Automatic closing

Function ENABLED: after an opening manoeuvre there is a pause (equal to the set pause time), after

which the control unit automatically starts a closing manoeuvre. The pause time is set by default to 30

seconds.

Function NOT ENABLED: the system works in “semi-automatic” mode.

L2 Close after photo

Function ENABLED: if the photocells intervene during the opening or closing manoeuvre, the pause time

drops to 5 seconds regardless of the set “pause time”. With “automatic closing” disabled, if the photocells

intervene during the opening or closing manoeuvre, the “automatic closing” activates with the set “pause

time”.

L3 Always Close

Function ENABLED: in the event of a blackout, even of short duration, 10 seconds after the electricity

is restored the control unit detects that the gate is open and automatically starts a closing manoeuvre,

preceded by 5 seconds of pre-ashing.

Function DISABLED: when the electricity is restored, the gate remains in the same position.

L4 Stand-by all

Function ENABLED: 1 minute after the manoeuvre is completed, the control unit will turn off the “Bluebus”

output (connected devices) and all the LEDs, with the exception of the Bluebus LED, which will ash at a

slower speed. When the control unit receives a command, it restores normal operation (with a short delay).

This function is used to reduce consumption – an important aspect when the unit is powered by batteries

or photovoltaic panels.

Loading...

Loading...