8 – ENGLISH

4.3 CONNECTING OTHER DEVICES TO THE

CONTROL UNIT

In any additional devices belonging to the system (e.g. tran-

sponder card reader, light for the key selector, etc.) must be

powered, they can be connected to the control unit using termi-

nals “SbS (positive)” and “Stop (negative)” (“Figure 7”). The

power supply voltage is 24 Vc with a maximum available cur-

rent of 200 mA.

l

The voltage available at the “SbS” and “STOP” ter-

minals remains even when the “Stand-by” function

is enabled on the board.

4.4 ADDRESSING OF DEVICES CONNECTED

WITH THE BLUEBUS SYSTEM

To allow the control unit to recognise the devices connected

through the “BlueBUS” system, these devices must be addressed.

This operation can be carried out by correctly positioning the

electrical jumper present in each device (also refer to the in-

struction manual of each device). Shown below is an address-

ing diagram for photocells, based on their type.

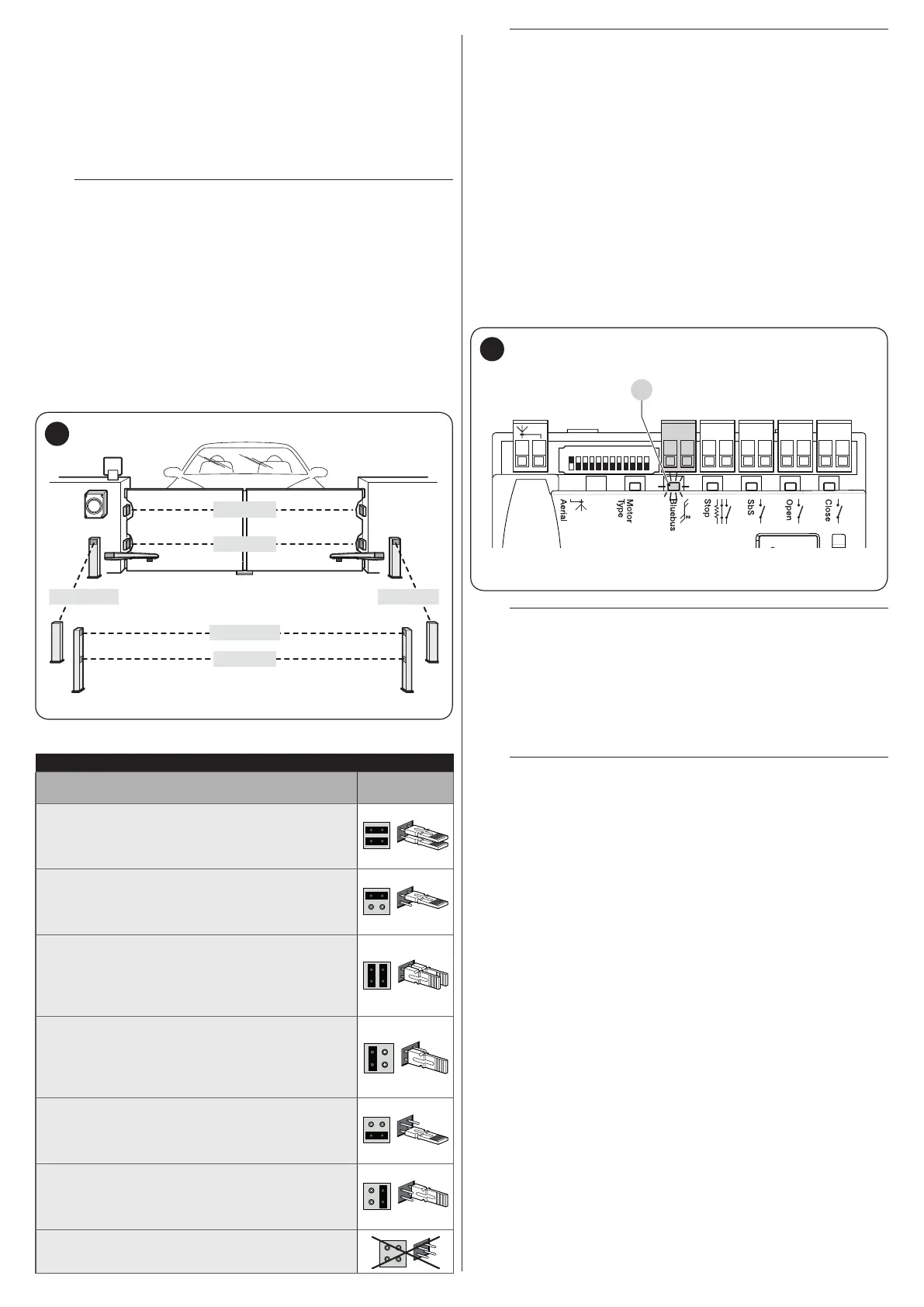

FOTO 1

FOTO

FOTO II

FOTO 1 II

FOTO 2 II FOTO 2

9

Table 3

PHOTOCELL ADDRESSES

Photocell

Position of the

jumpers

FOTO (PHOTO)

External photocell h = 50 activated during the

closing phase (stops and reverses the gate’s

movement)

FOTO II (PHOTO II)

External photocell h = 100 activated during the

closing phase (stops and reverses the gate’s

movement)

FOTO 1 (PHOTO 1)

Internal photocell h = 50 cm with activation

both during closing (stops and reverses the

movement) and during opening (stops and

restarts when the photocell disengages)

FOTO 1 II (PHOTO 1 II)

Internal photocell h = 100 cm with activation

both during closing (stops and reverses the

movement) and during opening (stops and

restarts when the photocell disengages)

FOTO 2 (PHOTO 2)

Internal photocell triggered during the

opening phase (stops and reverses the gate’s

movement)

FOTO 2 II (PHOTO 2 II)

Internal photocell triggered during the

opening phase (stops and reverses the gate’s

movement)

FOTO 3 (PHOTO 3)

CONFIGURATION NOT ALLOWED

m

At the end of the installation procedure, or after

photocells or other devices have been removed, it is

necessary to complete the learning procedure (see

the “Learning of connected devices” paragraph).

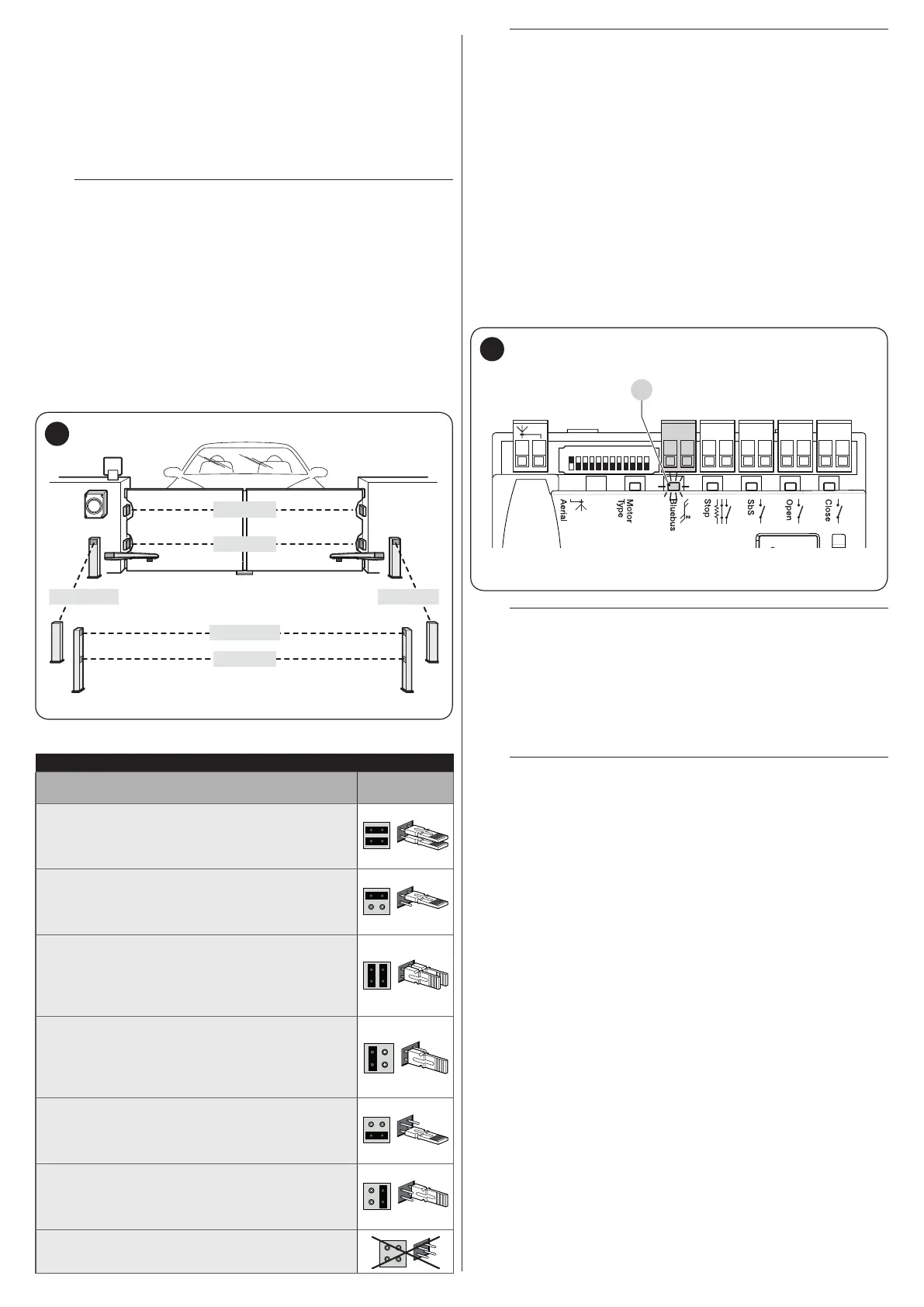

4.5 INITIAL START-UP AND ELECTRICAL

CONNECTIONS TEST

After powering the control unit, carry out the following checks

(“Figure 10”):

1. after a few seconds, check that the “Bluebus” (A) LED

ashes regularly with one ash per second

2. check that the LEDs of the photocells, both TX (transmis-

sion) and RX (reception), ash. The type of ash emitted

in this phase is not signicant

3. check that the warning light connected to the “Flash” out-

put is turned off.

CloseOpenSbSStop

Bluebus

1 2 3 4 5 6 7 8 9

10 11 12

A

10

a

If any one of these tests fails, disconnect the pow-

er supply to the control unit and check the various

electrical connections made previously.

4.6 LEARNING OF CONNECTED DEVICES

After the initial start-up, the control unit must recognise the de-

vices connected to the “Bluebus” and “Stop” inputs.

l

The learning phase must be carried out even if no

device is connected to the control unit.

The control unit can individually recognise the various devices

connected, thanks to the learning procedure, and detect possi-

ble anomalies.

For this to occur, the device learning procedure must be carried

out whenever a device is added or removed.

Loading...

Loading...