44952001TH Rev.2

7-69

Oki Data CONFIDENTIAL

7. TROUBLESHOOTING PROCEDURES

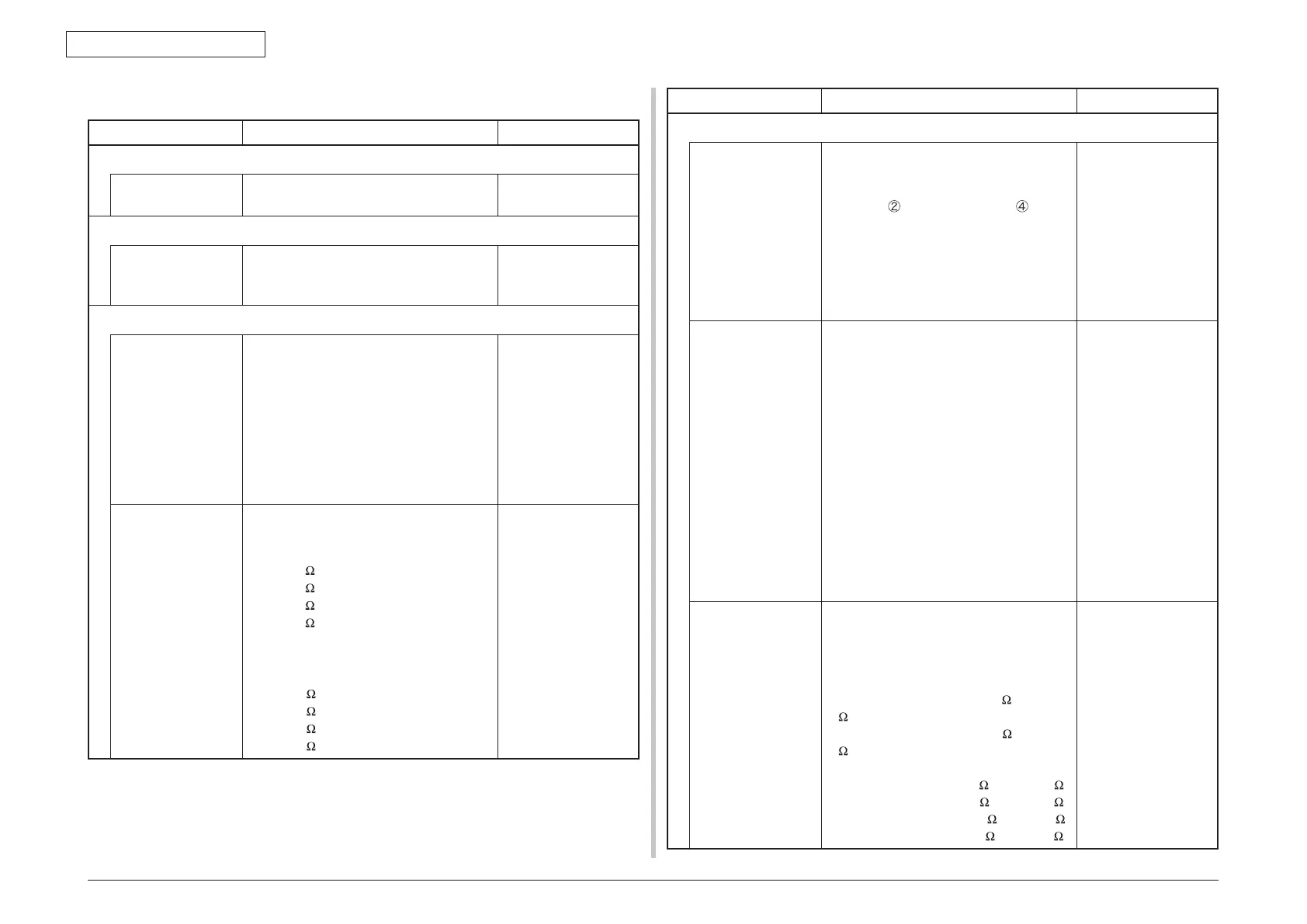

(6-2) Jam occurs immediately after a paper is taken into printer.

Check item Checking method Action in case of NG

(6-2-1) Check condition of the paper running path

Paper running path

on the belt.

Remove the ID unit and check if paper is

jammedornotinthepaperrunningpath.

Removethejammed

paper.

(6-2-2) Check condition of the mechanical parts

Check the sensor

lever of the WR

sensor.

Check if shape and movement of the sensor

levers have any abnormality or not.

Replace the sensor

lever with the good

sensor lever.

(6-2-3) Motor operation check

Paper feed motor

driver, belt motor

driver and ID motor

Confirm that the paper feed motor, belt

motor and ID motor work normally by

using the Motor & Clutch Test of the self-

diagnostic mode.

Check if any load exists or not.

Feed motor driving

cord, image drum

motor driving cord,

belt motor, fuser

driving cord

If any attempt of using

new ID unit or new belt

unit as a trial is going

to be made, be sure

to use the System

Maintenance Menu

FUSE KEEP MODE.

Paper feed motor,

belt motor

Pull out the CU/PU board BELT connector

③

, and check the following at the side of the

connector:

Several M

between Pin 1 and frame ground

Several M between Pin 2 and frame ground

Several M between Pin 3 and frame ground

Several M between Pin 4 and frame ground

Pull out the CU/PU board HOP connector

①

, and check the following at the side of the

connector:

Several M

between pin-1 – FG

Several M between pin-2 – FG

Several M between pin-3 – FG

Several M between pin-4 – FG

Replace the CU/PU

board.

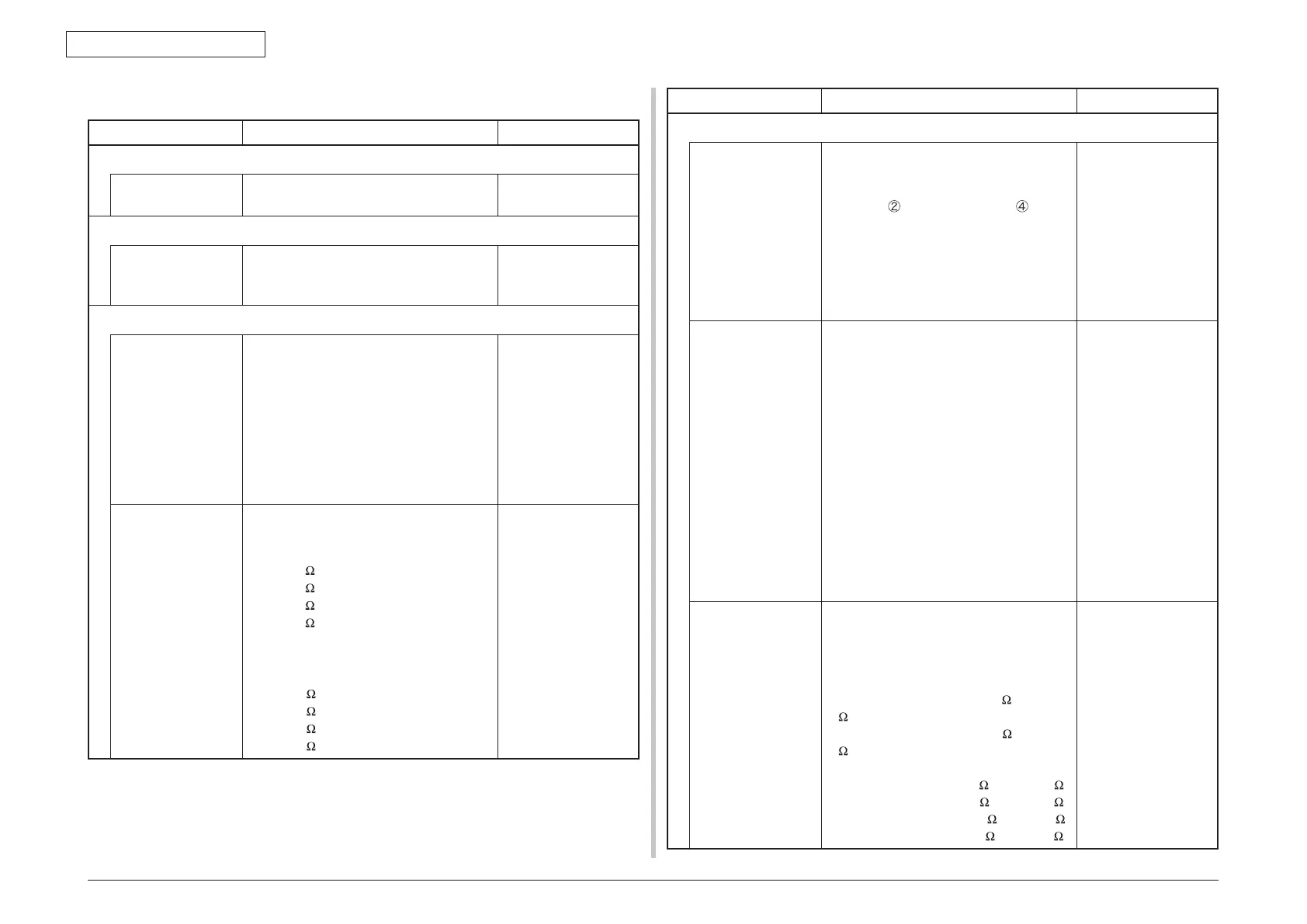

Check item Checking method Action in case of NG

(6-2-4) Check the system connection

Feed motor driving

cord, image drum

motor driving cord,

belt motor, fuser

driving cord

Check the connection condition of the

cables.

CU/PU board HOP connector

①

, DC ID

connector

, DCHEAT connector , BELT

connector

③

.

Check if the connector is connected in

the half-way only or not, and check if the

connector is inserted in a slanted angle or not.

Check also that cables are assembled

without any abnormality.

Normalizethe

connection condition.

Replace the cable with

the normal cable.

Feed motor driving

cord, image drum

motor driving cord,

belt motor driving

cord

Check that any cable is not pinched during

assembling of the printer.

Pull out the CU/PU board BELT connector

③

, and check the following at the sides of

the cords:

Short circuit between pin-1 – FG

Short circuit between pin-2 – FG

Short circuit between pin-3 – FG

Short circuit between pin-4 – FG

Pull out the CU/PU board HOP connector

①

, and check the following at the side of the

cords:

Short circuit between pin-1 – FG

Short circuit between pin-2 – FG

Short circuit between pin-3 – FG

Short circuit between pin-4 – FG

Replace the cable

with the good cable

thatnormalizesthe

connection condition.

Feed motor, belt

motor

Remove the respective connectors from

the board, and confirm that the following

resistance exists between the corresponding

pins, at the cable side.

CU/PU board HOP connector

①

Between pin-1-pin-2 Approx. 3.4 or approx.

5

.

Between pin-3-pin-4 Approx. 3.4

or approx.

5

.

CU/PU board BELT connector

③

Between pin-1-pin-2 Approx. 6.1 or approx. 3.5 .

Between pin-3-pin-4 Approx. 6.1 or approx. 3.5 .

Between pin-5-pin-6 Approx. 3.4

or approx. 5 .

Between pin-7-pin-8 Approx. 3.4

or approx. 5 .

Replace paper feed

motor, belt motor, ID

Up motor.

Loading...

Loading...