Absolute rotary encoder P**58

Installation

Subject to reasonable modifications due to technical advances. Copyright Pepperl+Fuchs, Printed in Germany

Pepperl+Fuchs Group • Tel.: Germany +49 621 776-0 • USA +1 330 4253555 • Singapore +65 67799091 • Internet http://www.pepperl-fuchs.com

Date of issue 01/15/04

8

2.3 Wiring of connection hood

Proceed as follows in the wiring:

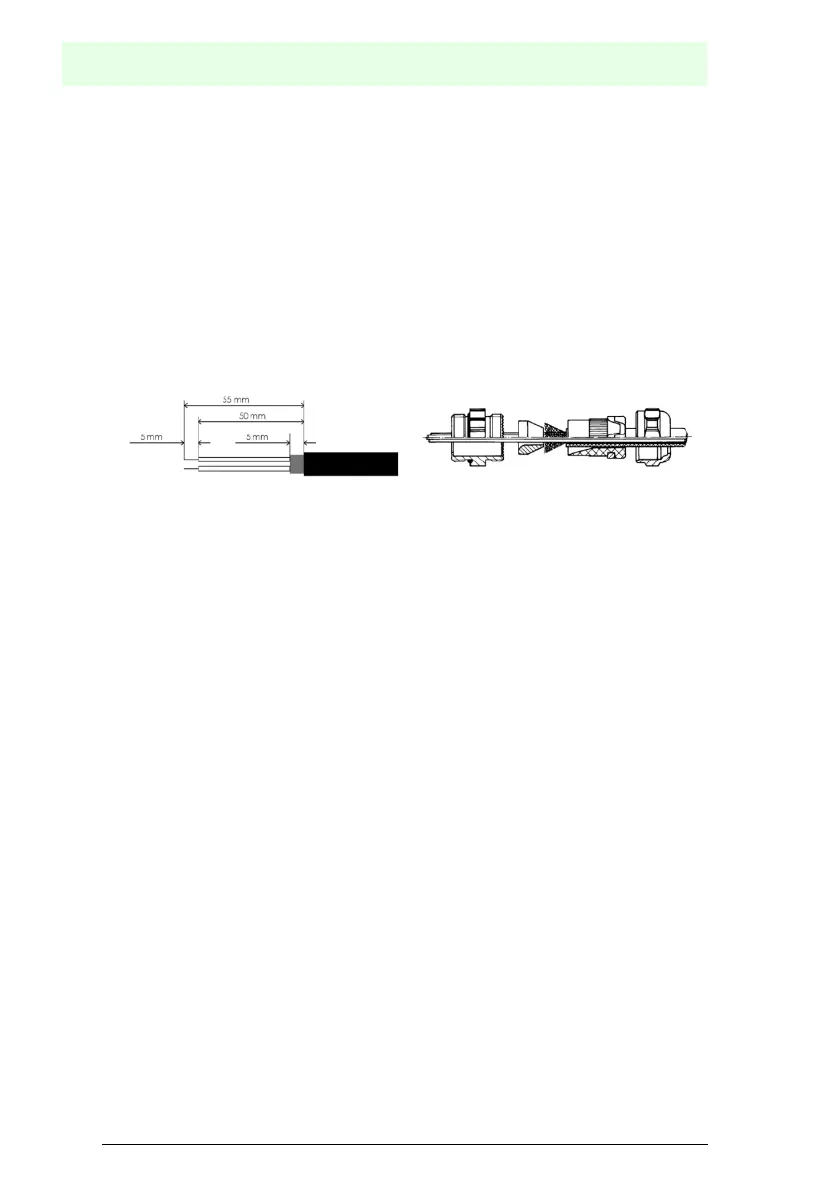

• Remove the pressure screw, pressure insert and cone from the cable gland.

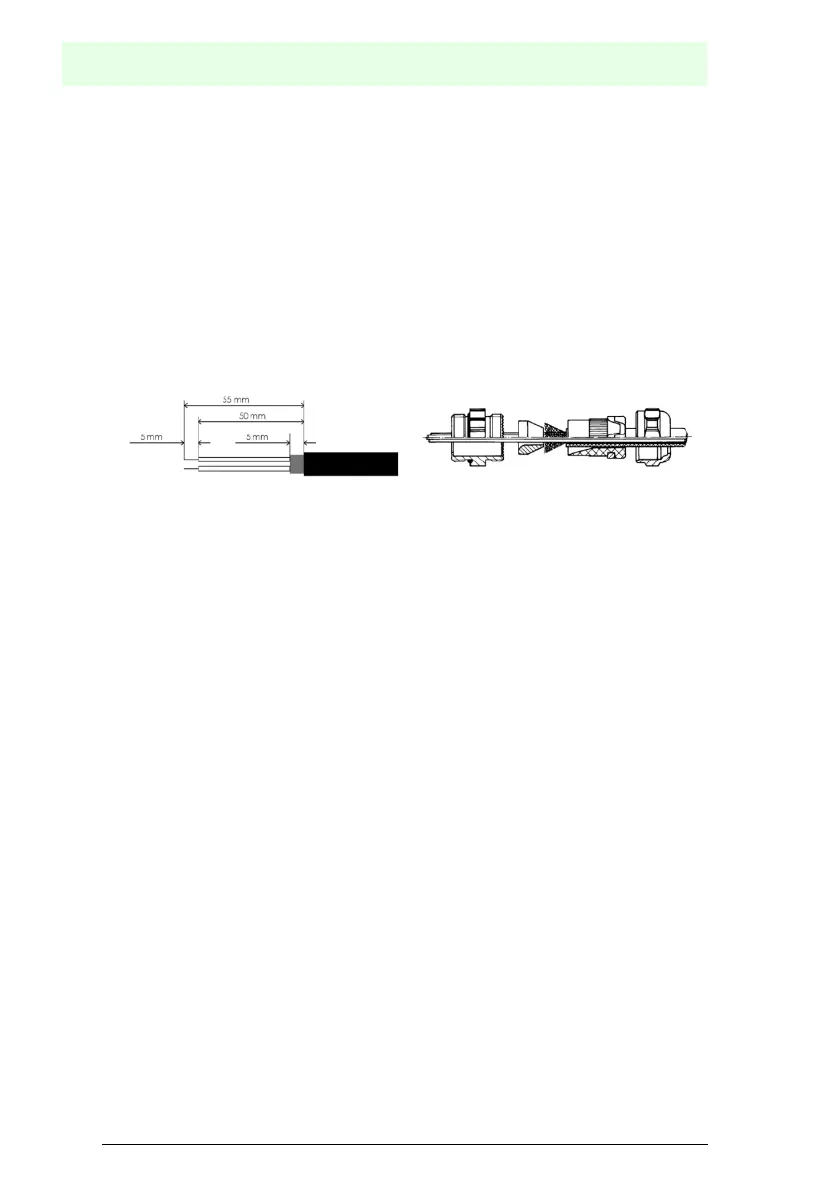

• Remove about 55 mm of the bus line covering and about 50 mm of the screening

mesh.

• Remove about 5 mm of insulation on the individual wires.

• After that, push the pressure screw and pressure insert onto the cable.

• Push the cone under the screen as shown in the drawing.

• Push the pressure screw, pressure insert and cone into the cable gland.

• Then tighten the pressure screw.

2.4 Connecting the screen line

To achieve the best interference immunity possible, the transfer of signals between

the system components should be via shielded lines with a shield seating on either

side. With certain system configurations an equalisation current can flow through the

shield connected on both sides of the cables. Because of this, a potential equalisation

line is recommended.

2.5 Notes on mechanical fitting and the electrical connection

Please observe the following items:

Do not drop the rotary encoder or expose it to significant vibration. It is a precision

instrument.

Do not open the rotary encoder housing (this does not mean you should not remove

the hood). Opening or closing the device improperly may damage it or result in

contamination.

The rotary encoder shaft must be connected with the shaft to be measured by means

of a suitable coupling. The purpose of this coupling is to absorb blows and imbalances

and prevent major forces from reaching the rotary encoder shaft. Suitable couplings

are available from Pepperl+Fuchs.

Rotary encoders are sturdy, but they should be protected by suitable protective

measures when used in a very harsh environment. In particular, they should not be

fitted to make them suitable for holding grips or stepping blocks.

Commissioning and operation of this electrical device must only be performed by

qualified personnel. This means persons who are authorised to place devices,

systems and circuits in service, ground them and identify them with appropriate

markings according to the latest state of fail-safe technology.

No electrical changes must be made to the rotary encoder.

Loading...

Loading...