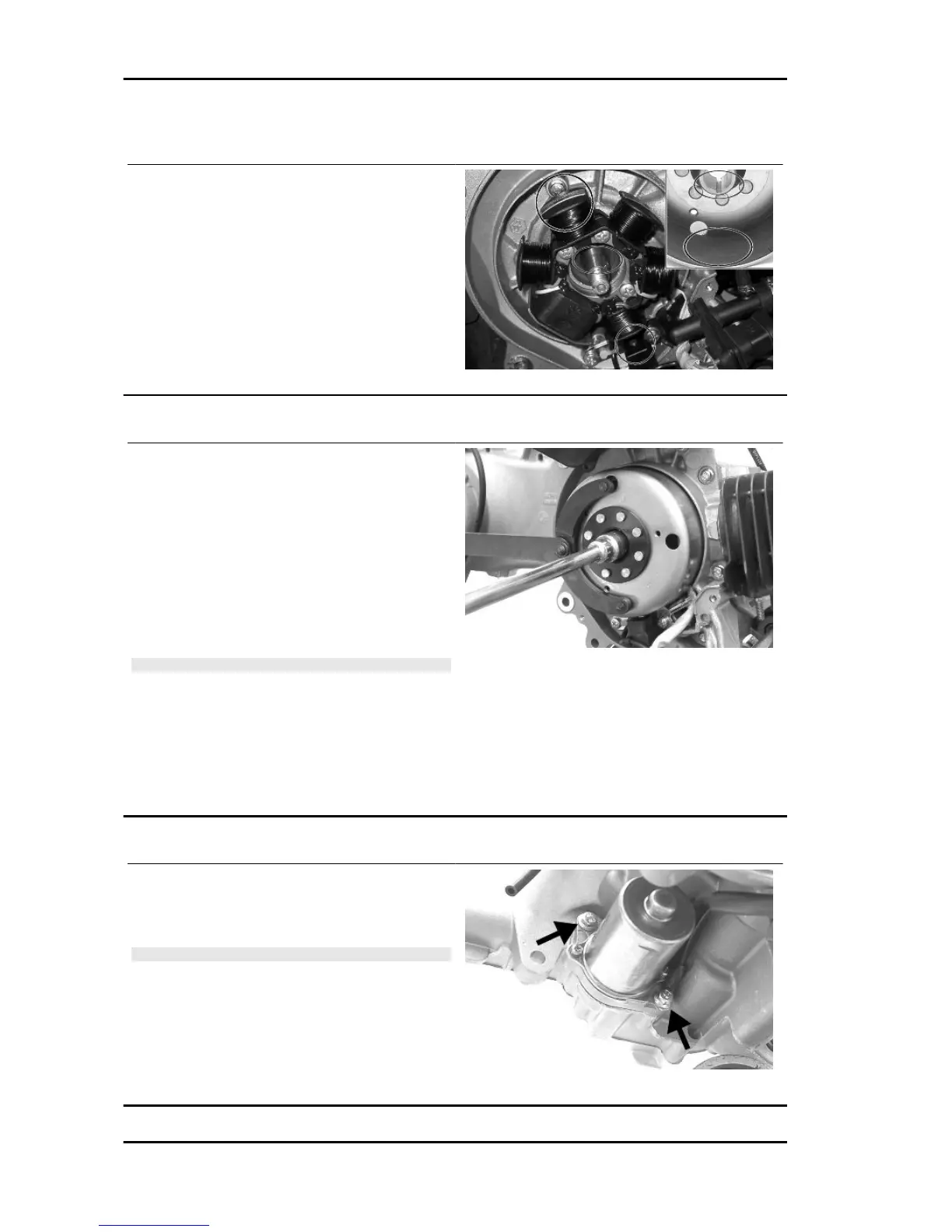

Inspecting the flywheel components

- Check the condition of the flywheel and any dis-

tortions that might cause rubbing on the stator and

on the Pick-Up.

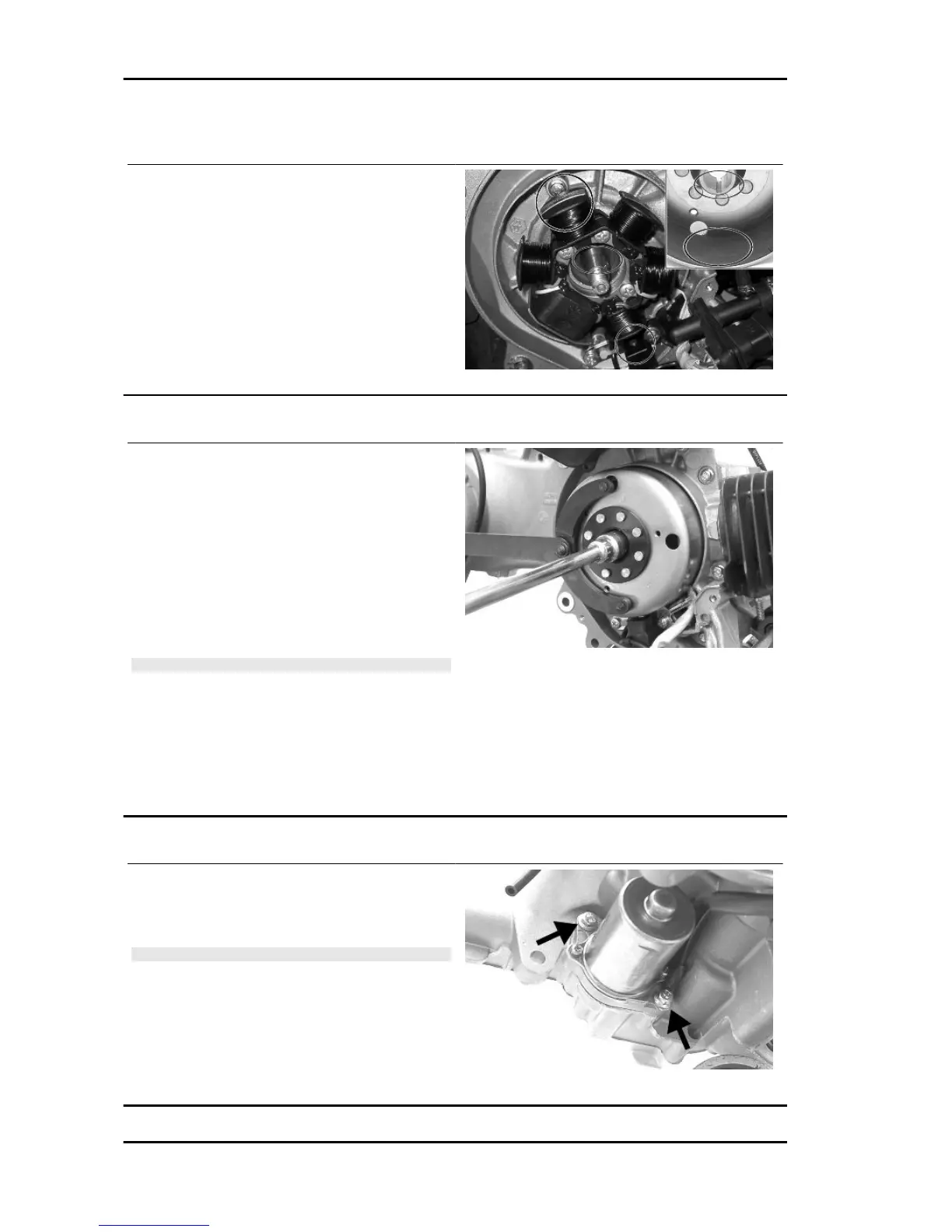

Refitting the flywheel magneto

- Fit the flywheel being careful to insert the key

properly.

- Lock the flywheel nut at the prescribed torque

- Check the Pick-Up air gap.

- The air gap may not be modified in the fitting of

the Pick-Up.

- Other values derive from deformations visible on

the Pick-Up support.

N.B.

A VARIATION OF THE AIR GAP DISTANCE

CAN LEAD TO A VARIATION IN THE IGNITION

ADVANCE SUCH AS TO CAUSE PINGING,

KNOCKING ETC.

Locking torques (N*m)

Flywheel nut 40 to 44 N.m

Refitting the starter motor

- Fit a new O-ring on the starter and lubricate it.

- Fit the starter on the crankcase, locking the two

screws to the prescribed torque.

N.B.

REFIT THE REMAINING PARTS AS DESCRI-

BED IN THE CYLINDER HEAD, TIMING, LUBRI-

CATION, FLYWHEEL AND TRANSMISSION

CHAPTERS.

Locking torques (N*m)

Starter motor screws 11 ÷ 13

Engine NRG Power DT

ENG - 20

Loading...

Loading...