WHEELS & TIRES 6 - 6

DIAGNOSIS AND TESTING -

TIRE NOISE OR VIBRATION

Radial-ply tires are sensitive to force impulses

caused by improper mounting, vibration, wheel

defects, or possibly tire imbalance.

To find out if tires are causing the noise or

vibration, drive the vehicle over a smooth road at

varying speeds. Note the noise level during

acceleration and deceleration. The motor and

differential noises will change as speed varies,

while the tire noise will usually remain constant.

REPAIRING LEAKS

For proper repairing, a radial tire must be removed

from the wheel. Repairs should only be made if the

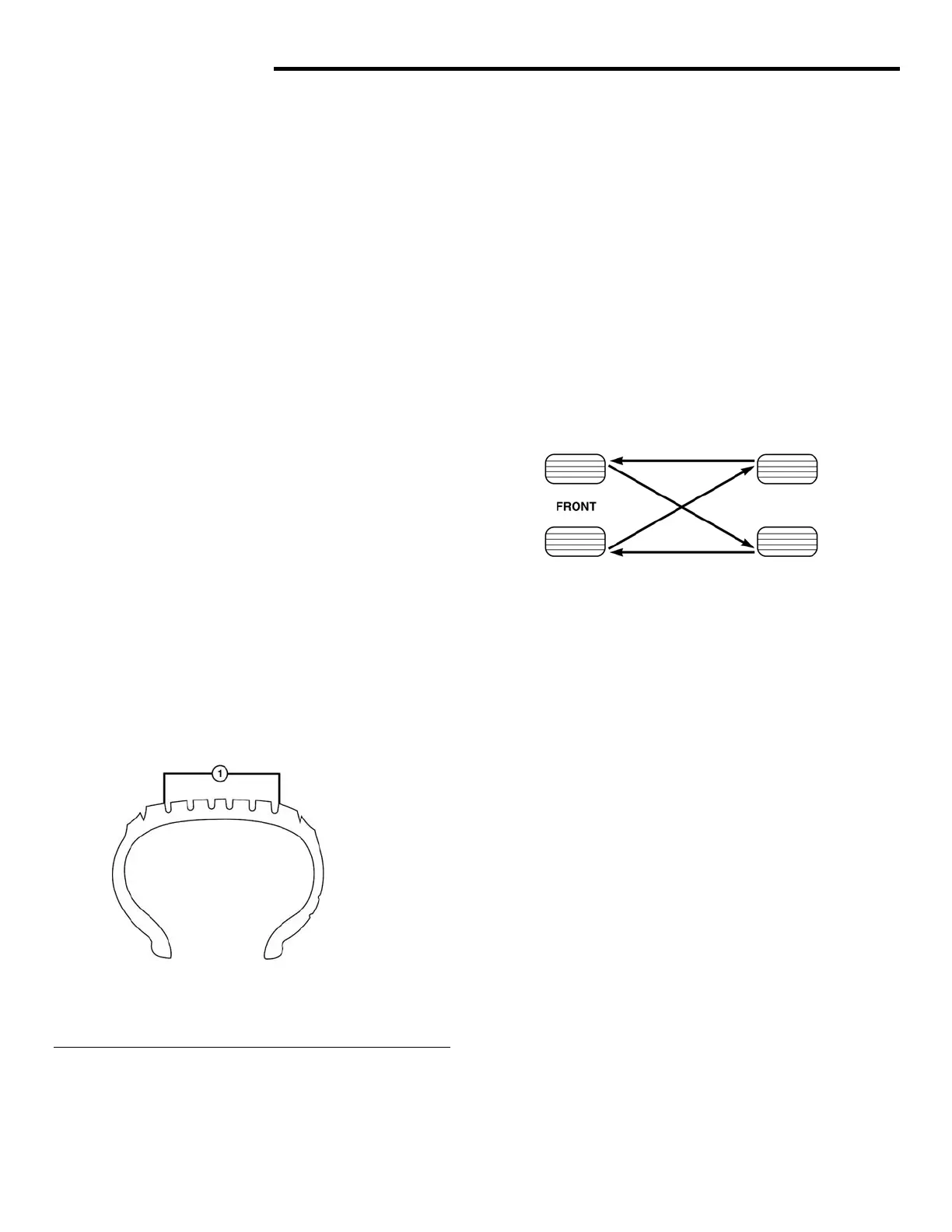

defect, or puncture, is in the tread area (Fig. 2).

The tire should be replaced if the puncture is

located in the sidewall.

Deflate tire completely before removing the tire

from the wheel. Use lubrication such as a mild

soap solution when dismounting or mounting tire.

Use tools free of burrs or sharp edges that could

damage the tire or wheel rim.

Before mounting tire on wheel, make sure all rust is

removed from the rim bead and repaint if

necessary.

Fig 2 Tire Repair Area

1 - Repairable area

ROTATION

Tires on the front and rear operate at different loads

and perform different steering, driving, and braking

functions. For these reasons they wear at unequal

rates and tend to develop irregular wear patterns.

Rotating the tires at 500 miles or as needed. The

benefits of tire rotation are:

• Increase tread life

• Maintain traction levels

• A smooth, quiet ride

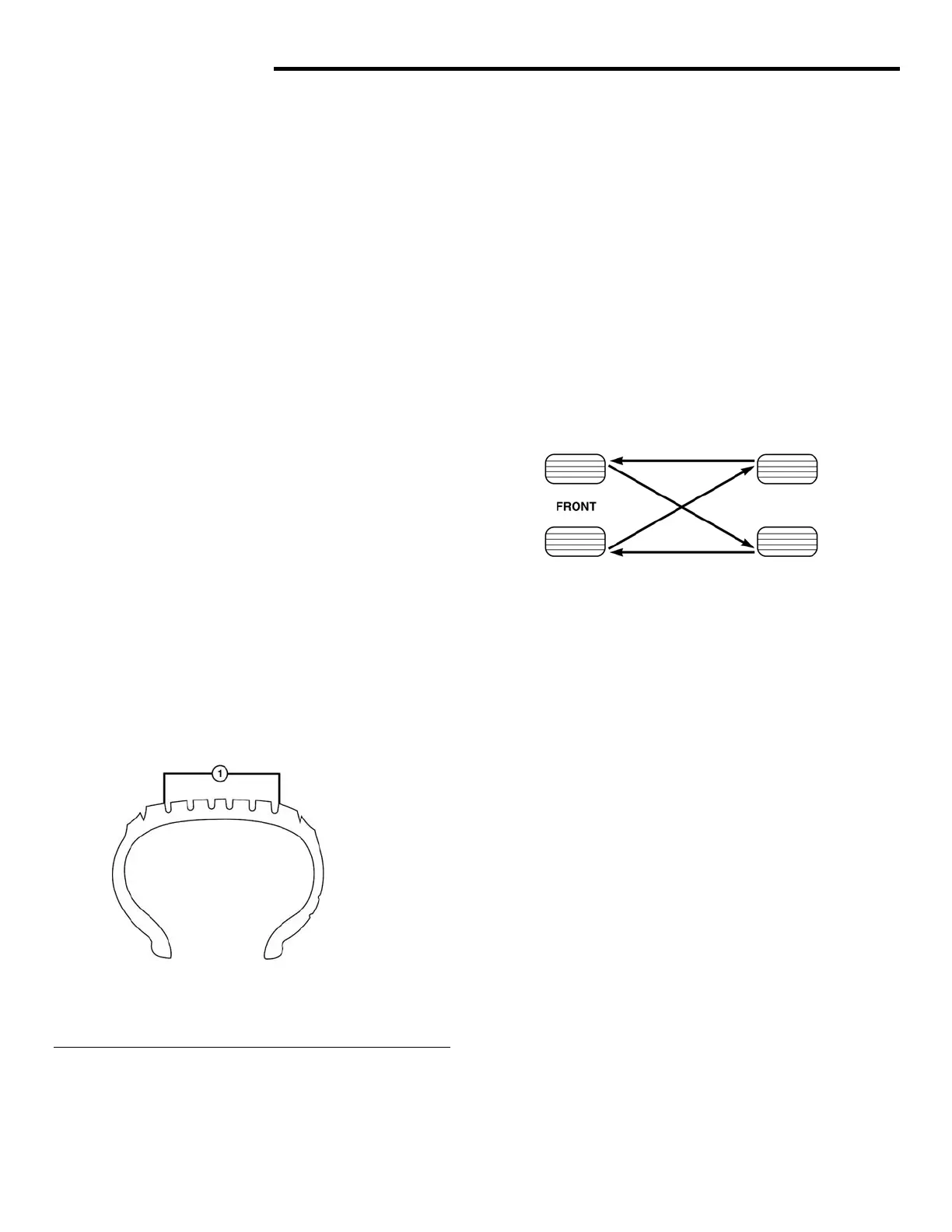

The suggested method of tire rotation is (Fig. 3).

Other rotation methods can be used, but they will

not provide all the tire longevity benefits.

Fig. 3 Tire Rotation Pattern

WHEELS

DESCRIPTION

All models use stamped steel wheels. Every wheel

has raised sections between the rim flanges and

rim drop well called safety humps.

Initial inflation of the tire forces the bead over these

raised sections. In case of rapid loss of air

pressure, the raised sections help hold the tire on

the wheel.

The wheel nuts are designed for this specific

application. Do not use replacement nuts with a

different design or lesser quality.

GEM Service Manual November 2007

Loading...

Loading...