FUEL SYSTEM/CARBURETION

4.16

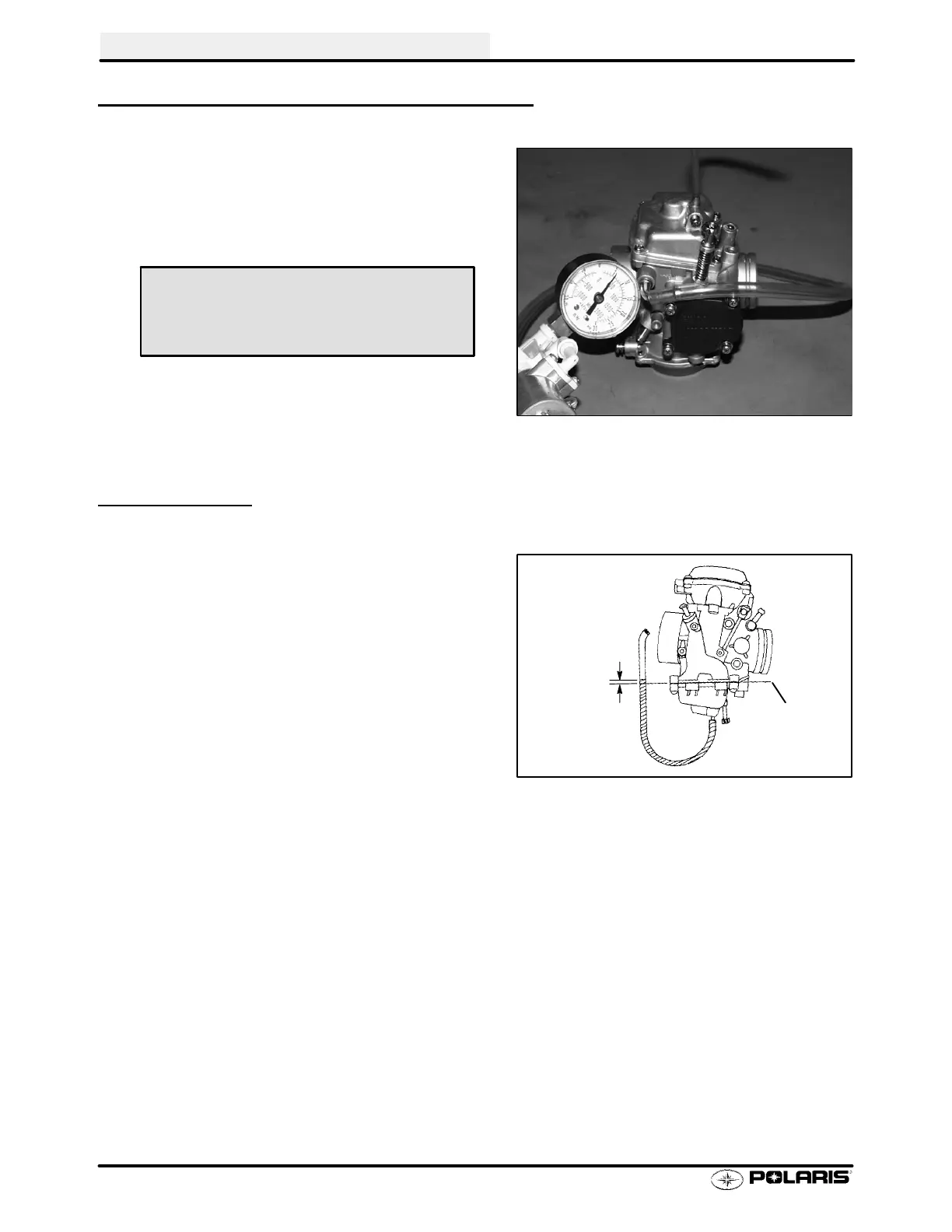

NEEDLE AND SEAT LEAKAGE TEST

1. Installthefloat bowl. Invert the carburetorandinstalla

Mity-Vac™ (PN 2870975) to the fuel inlet fitting. Apply

5 PSI pressure to inlet fitting. The needle and seat

shouldhold pressureindefinitely. Ifnot,inspectneedle

and seat and seat O-ring.

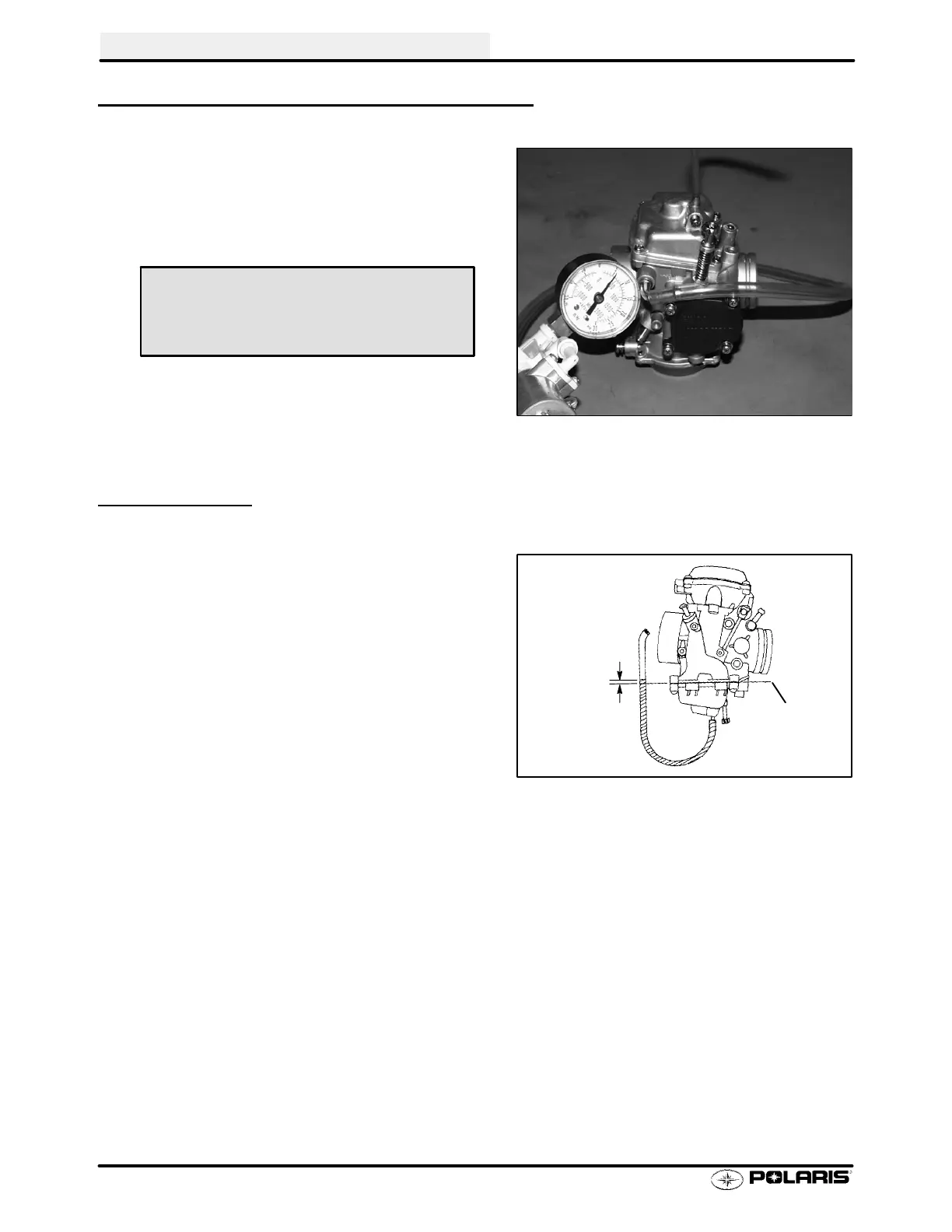

FUEL LEVEL

A fuel level test can be performed on some models if the

drain hose fitting is accessible. Be sure to re-attach the

bowl drain hose after performing the test. A fuel level test

allows you to observe the height of thefuel inthe floatbowl

without removing the carburetor. The fuel level can be ob-

served with the engine either running or shut off, however,

engine must run briefly to allow fuel level to stabilize..

1. Attachaclearlinetodrainfitting. Besurelinefitstightly

on fitting. Position hose along side of carburetor as

shown.

2. Open bowl drain screw by turning counterclockwise

approximatelytwoturns. Startandrunenginefor3to5

secondstoallowfuelleveltostabilizeintheline. Iflevel

is out of specification, remove carburetor and inspect

inlet needle and seat, float height, passages, etc.

3. If aline wasremoved toperformthisprocedure, itmust

be replaced.

Mity Vac™ PN 2870975

1.5 mm

.060″

Bowl Mating

Surface

Loading...

Loading...