ENGINE

3.23

AUTOMATIC COMPRESSION RELEASE REMOVAL/INSPECTION

NOTE: The automatic compression release mecha-

nism can be inspected and serviced without removing

the camshaft from the cylinderhead. The actuator ball

in the camshaft is not replaceable. Replace the cam-

shaftasanassemblyiftheactuatorballiswornordam-

aged.

1. Check release lever shaft for smooth operation

throughout theentire rangeof rotation. Thespring

should hold the shaft weight against the stop pin.

In this position, the actuator ball will be held

outward in the compression release mode.

2. Remove release lever shaft and return spring.

3. Inspect shaft for wear or galling.

4. Inspect lobe on end of release lever shaft and

actuator ball for wear and replace if necessary.

AUTOMATIC COMPRESSION RELEASE INSTALLATION

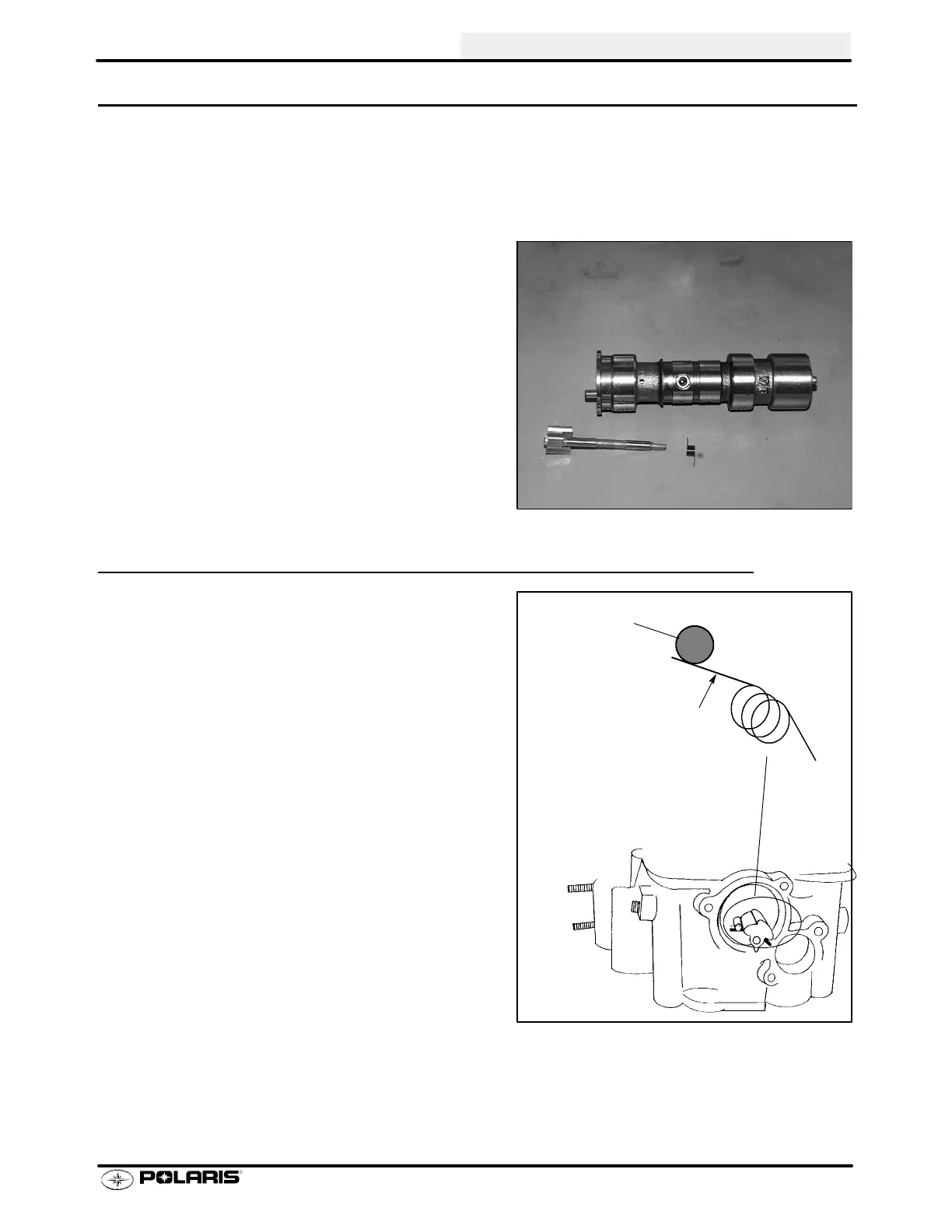

1. Slide spring onto shaft.

2. Apply engine oil to release lever shaft.

The actuator ball must be held outward to allow instal-

lation of the release lever shaft.

If Camshaft Is Removed From Engine:

3. T urn the camshaft until the actuator ball is in the

lowest position and install the release lever shaft.

If Camshaft Is Installed In The Engine:

4. Use a small magnet to draw the actuator ball

outward, or rotate the engine until the cam lobes

face upward and install release lever shaft.

5. Position camshaft as shown at bottom of

illustration at right.

6. Place arm of spring under stop pin as shown and

pushreleaseleverinwarduntilfully seated. Donot

pre-wind the spring one full turn or the

compression release will not disengage when the

engine starts. Check operation of mechanism as

outlined in step 1 of Removal (above).

NOTE: When shaft is properly installed, actuator

ball will beheldinthe “out” position. It is important

to note that spring pressure is very light.

Spring in relaxed position

Stop pin

Loading...

Loading...