MAINTENANCE

2.21

LIQUID COOLING SYSTEM OVERVIEW

Theenginecoolantleveliscontrolledormaintainedbytherecoverysystem. T herecoverysystemcomponents

are the recovery bot t le, radiat or filler neck , radiat or pres sur e cap and connect ing hose.

Ascoolantoperatingtem perat ur eincreases,theex panding(heat ed)excessc oolantisfor cedoutoftheradiat or

pastt hepress ur ecapandint ot herecov erybot t le. Asenginecoolantt emper at ur edecreas esthecontr act ing

(cooled) coolant is drawn back up f rom t he tank past the pressur e cap and into the radiat or.

S Somecoolantleveldroponnewmachinesisnormalasthesystemispurgingitselfoftr appedair. O bserve

coolant levels oft en during the break-in period.

S Overheating of engine could occur if air is not fully purged from system.

S P olaris Pr emium 60/ 40 is alr eady premix ed and ready to use. Do not dilute with water.

COOLANT STRENGTH / TYPE

Test the strength of the coolant using an antifreeze

hydrometer.

S A 50/50 or 60/40 mixture of antifreeze and distilled wa-

ter will provide the optimum cooling, corrosion protec-

tion, and antifreeze protection.

S Donot usetap water,straight antifreeze, or straight wa-

ter in the system. Tap water contains minerals and im-

purities which build up in the system.

S Straight water or antifreeze may cause the system to

freeze, corrode, or overheat.

COOLING SYSTEM HOSES

1. Inspectallhosesforcracks,deterioration,abrasionor

leaks. Replace if necessary.

2. Check tightness of all hose clamps.

CAUTION:Do not over-tighten hose clamps at radiator,or

radiator fitting may distort, causing a restriction to coolant

flow . Radiator hose clamp torque is 36 inch lbs.

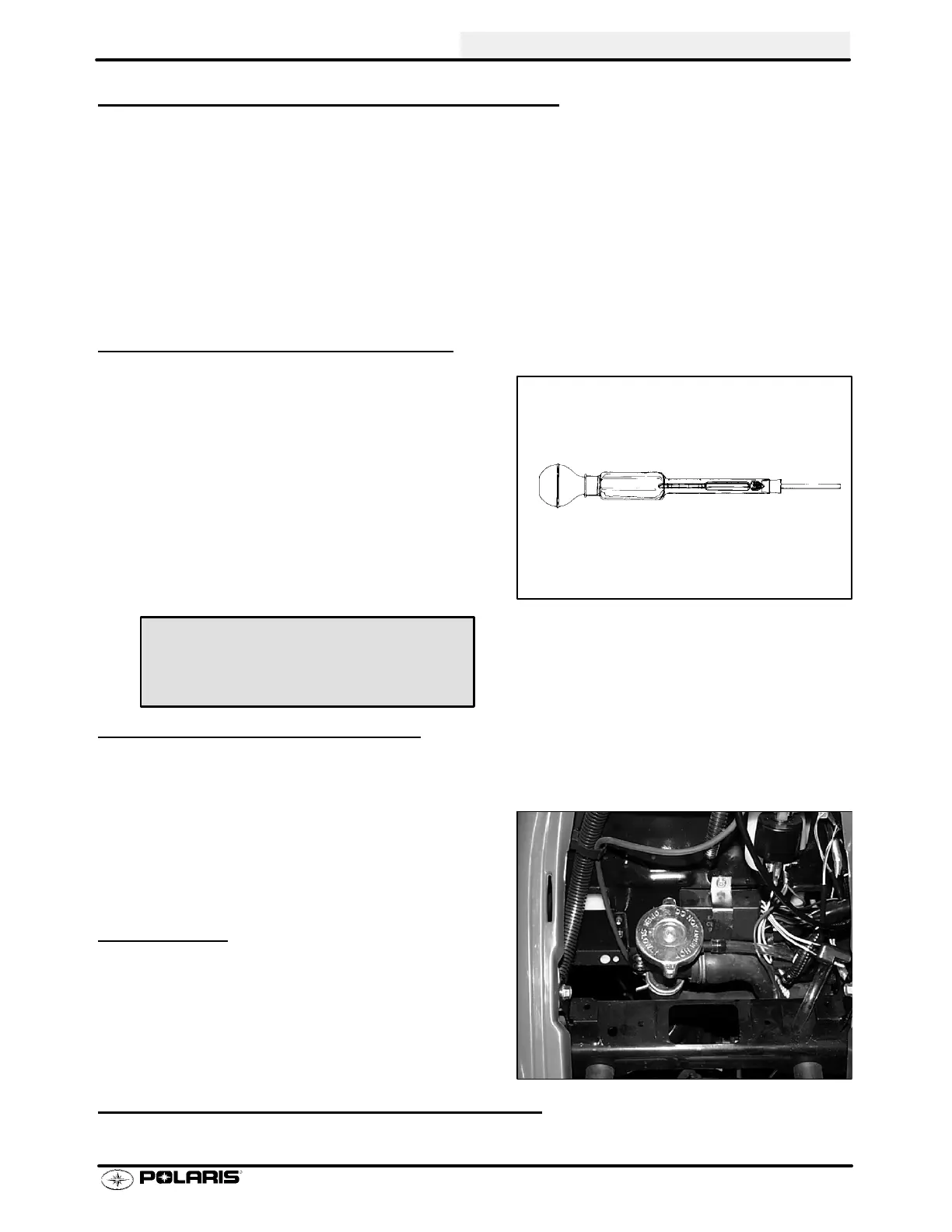

RADIATOR

1. Check radiator air passages for restrictions or

damage.

2. Carefully straighten any bent radiator fins.

3. Remove any obstructions with compressed air or low

pressure water.

COOLING SYSTEM PRESSURE TEST

Refer to page 3.6 for pressure test procedure.

Antifreeze Hydrometer

Polaris 60/40 Anti-Freeze / Coolant

PN 2871323

Loading...

Loading...