T-one ULS

Rev. 06/18 3/26

“Taper tension” function

The “Taper tension” function is normally used to avoid that the material on the reel is too tensioned (or not

sufficiently tensioned) as the diameter increases, and vice versa. It allows to change the brake use

percentage automatically, according to the diameter of the reel, and it is normally used on the rewinders, but

in some cases, it is also useful on the unwinders.

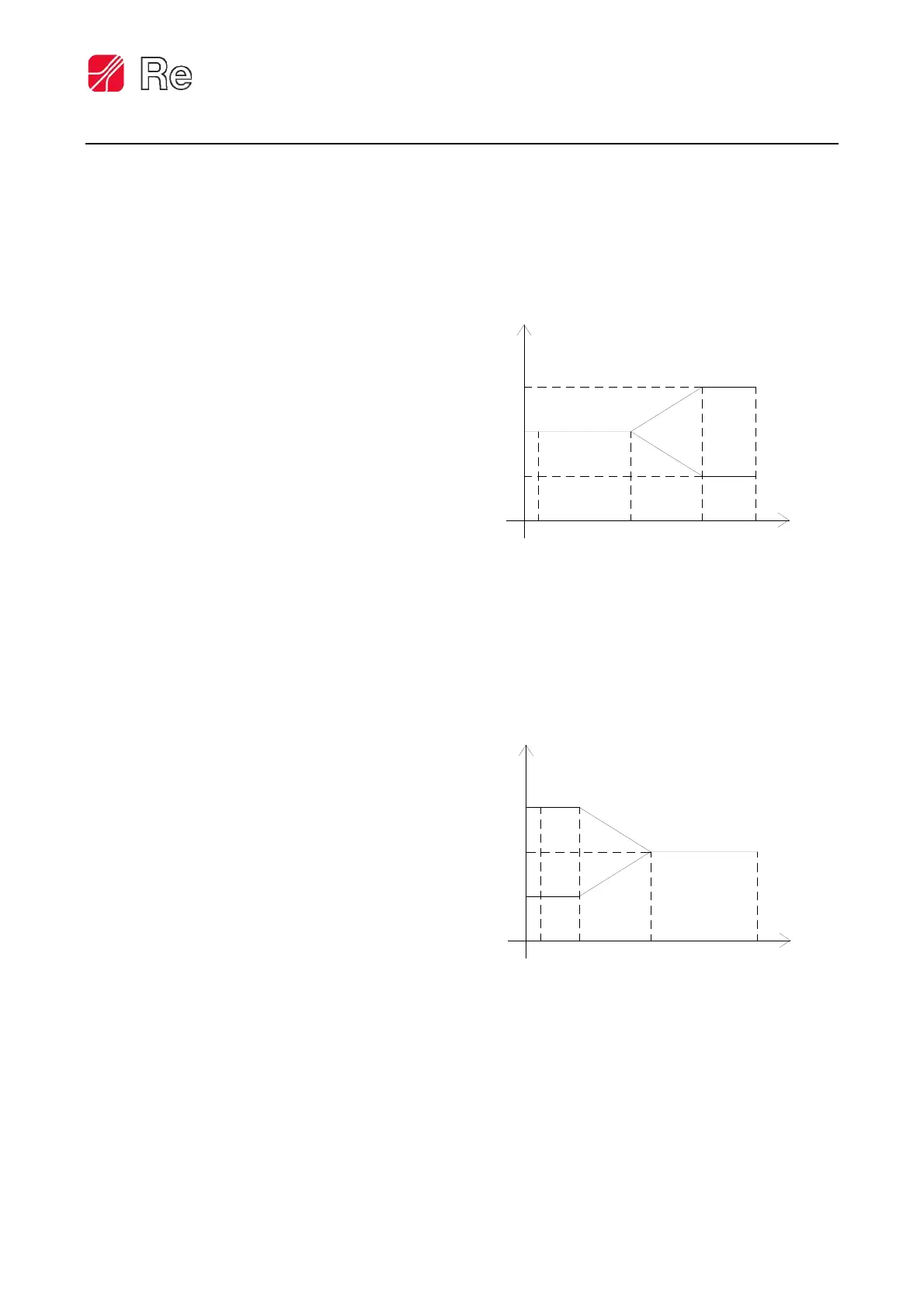

Rewinders:

The use percentage of brake or clutch has

a value calculated according to the

diameter until the diameter is less than

the Taper start value set (F.11), then it

decreases (or increases) as the diameter

increases, until it reaches, at the Taper

end diameter (F.12), the set point value

decreased (or increased) by the Taper

percentage set (F.10).

Example:

if you set: F.10 = -20 (Taper percentage) there will be: OUT = OUT if diameter < 200

F.11 = 200 (Taper start diameter) OUT = OUT - 10% if diameter = 500

F.12 = 800 (Taper end diameter) OUT = OUT - 20% if diameter = 800

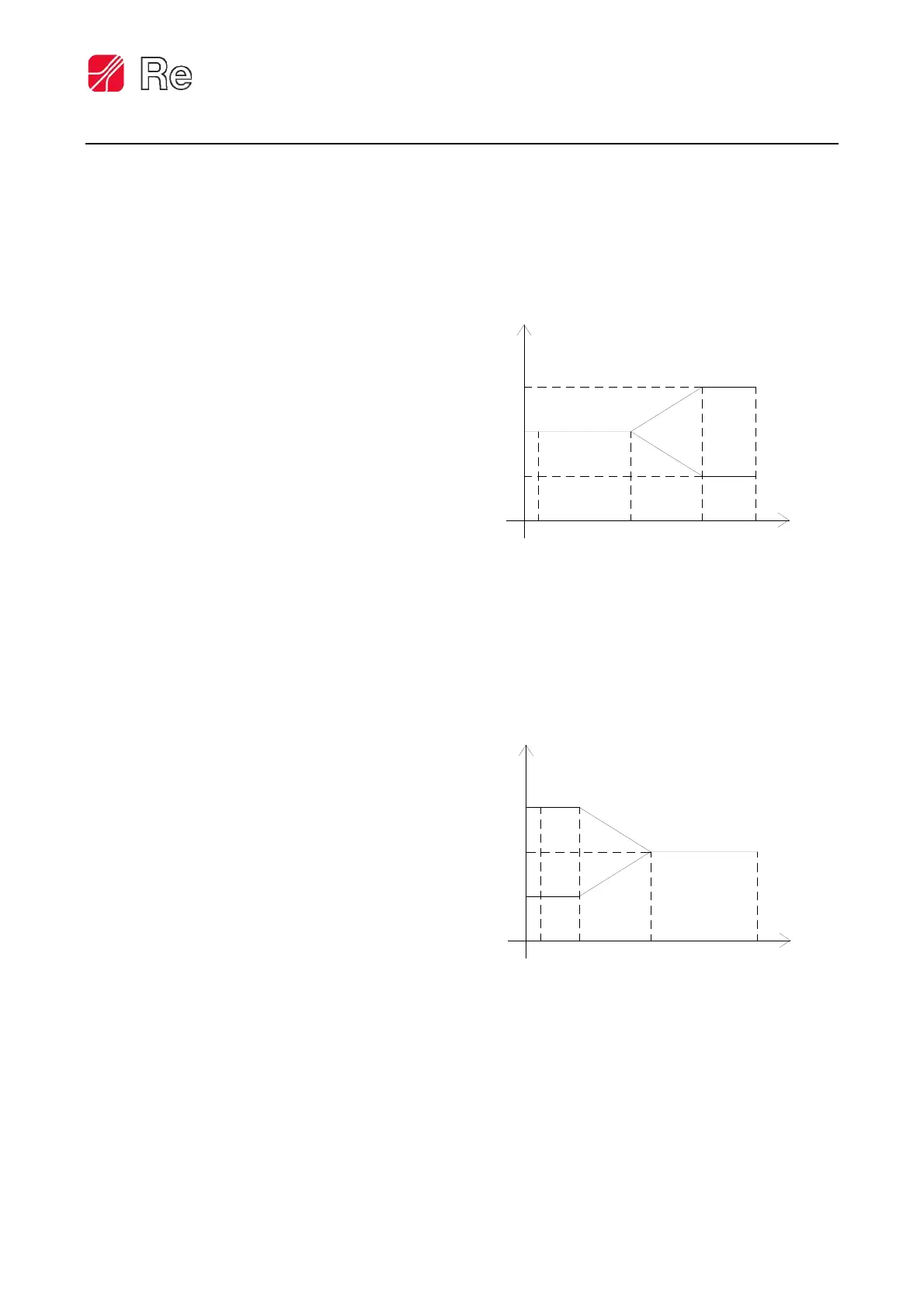

Unwinders:

The use percentage of brake or clutch

has a value calculated according to the

diameter until the diameter is more than

the Taper start value set (F.11), then it

decreases (or increases) as the diameter

decreases, until it reaches, at the Taper

end diameter (F.12), the set point value

decreased (or increased) by the Taper

percentage set (F.10).

Example

if you set: F.10 = -20 (Taper percentage) there will be: OUT = OUT if diameter > 800

F.11 = 800 (Taper start diameter) OUT = OUT - 10% if diameter = 500

F.12 = 2

T

r

n

i

m

r

T =

T - 2

if

i

m

r = 2

Setpoint (kg)

% taper > 0

% taper < 0

D

min

D

start

taper

D

end

taper

D

max

Diameter

(mm or inch)

Setpoint (Kg)

% taper > 0

% taper < 0

D

min

D

end

taper

D

start

taper

D

max

Diameter

(mm or inch)

Loading...

Loading...