Chapter 3 Performance Test RIGOL

Service Guide for DS1000E, DS1000D Series

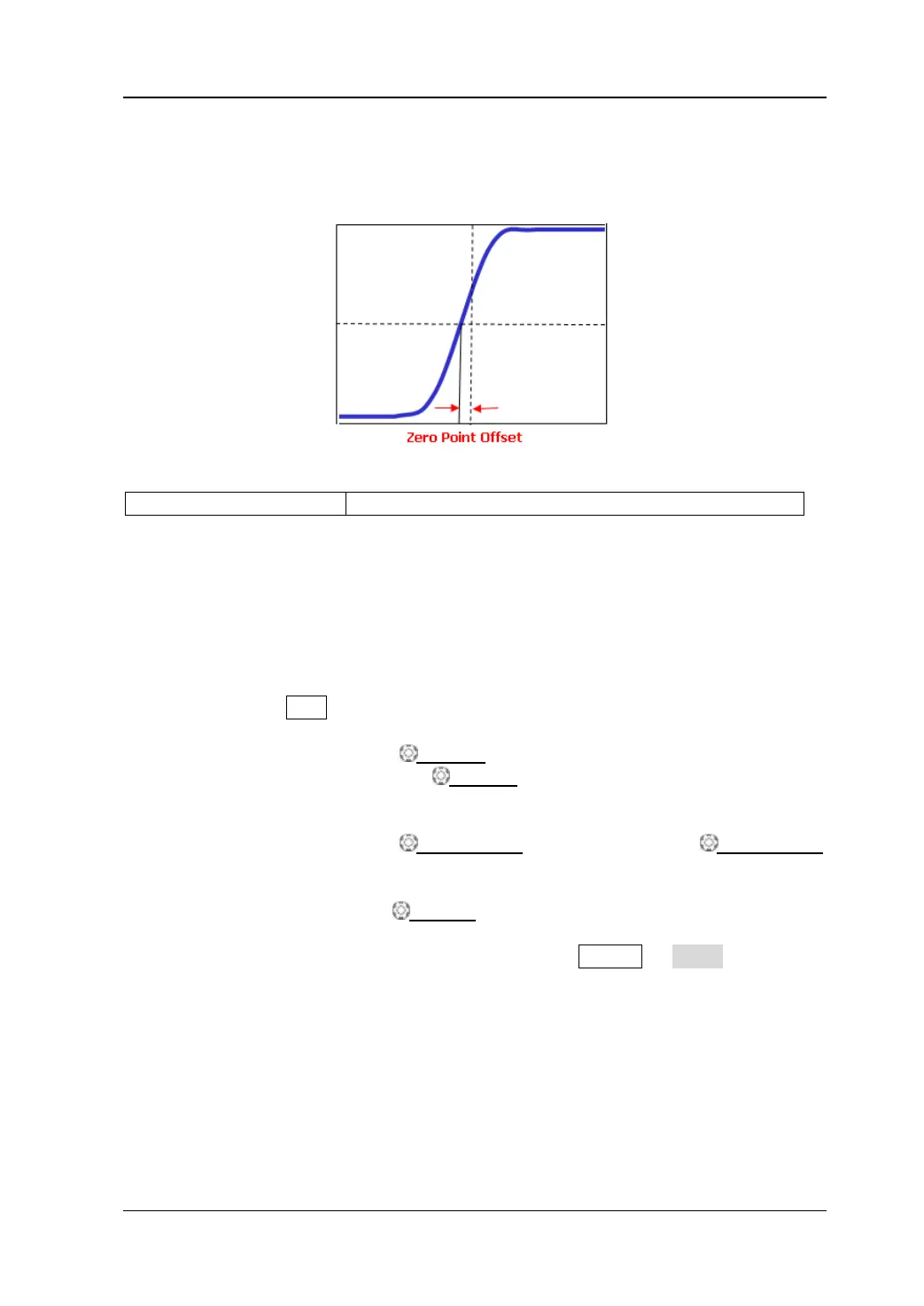

Zero Point Offset Test

Zero point offset is defined as the offset of the crossing point of the waveform and the

trigger level relative to the trigger position as shown in the figure below.

Specification:

Test Devices: Fluke 9500B

Test Procedures:

1) Connect the active head of Fluke 9500B to CH1 of the oscilloscope.

2) Output a fast edge signal with 150 ps rise time and 600 mV amplitude from

Fluke 9500B.

3) Configure the oscilloscope:

a) Press CH1 in the vertical control area (VERTICAL) at the front panel to

enable CH1.

b) Rotate VERTICAL SCALE to set the vertical scale to 100 mV/div.

c) Rotate HORIZONTAL SCALE to set the horizontal time base to 2

ns (for 50 MHz bandwidth oscilloscopes, set the horizontal time base to

5 ns).

d) Rotate VERTICAL POSITION and HORIZONTAL POSITION

to set the vertical position and horizontal position to appropriate values

respectively.

e) Rotate TRIGGER LEVEL to adjust the trigger level to the middle of

the screen.

4) Observe the display of the oscilloscope. Press Cursor Mode “Manual”

to enable the manual cursor function to measure the zero point offset and

record the measurement result.

5) Keep other settings unchanged and adjust the amplitude of the fast edge

signal to 3 V.

6) Set the vertical scale to 500 mV/div. Measure the zero point offset according

to the above method and record the test result.

7) Turn CH1 off. Repeat the above test steps to measure CH2 and record the

test results.

Loading...

Loading...