Electrical connection

8.3 System integration

S-1FT7 synchronous motors

370 Configuration Manual, 09/2018, A5E45099423B AA

Rotating a connector on the motor

Power connectors and signal connectors can be rotated to a different angle to a limited

extent.

Use a suitable socket connector to rotate the angled connector.

Unscrew and open the socket connector completely to avoid damaging the pin contacts.

On encoders with an integrated Sensor Module (DQI), the cable outlet toward the top is fixed

and cannot be changed.

Note

Rotating the connectors

•

Do not exceed the permissible range of rotation.

To ensure the degree of protection, do not rotate more than 10 times.

Rotate the connector using a mating connector that matches the connector thread. Only

rotate Sensor Modules by hand. Use of tools is not permissible.

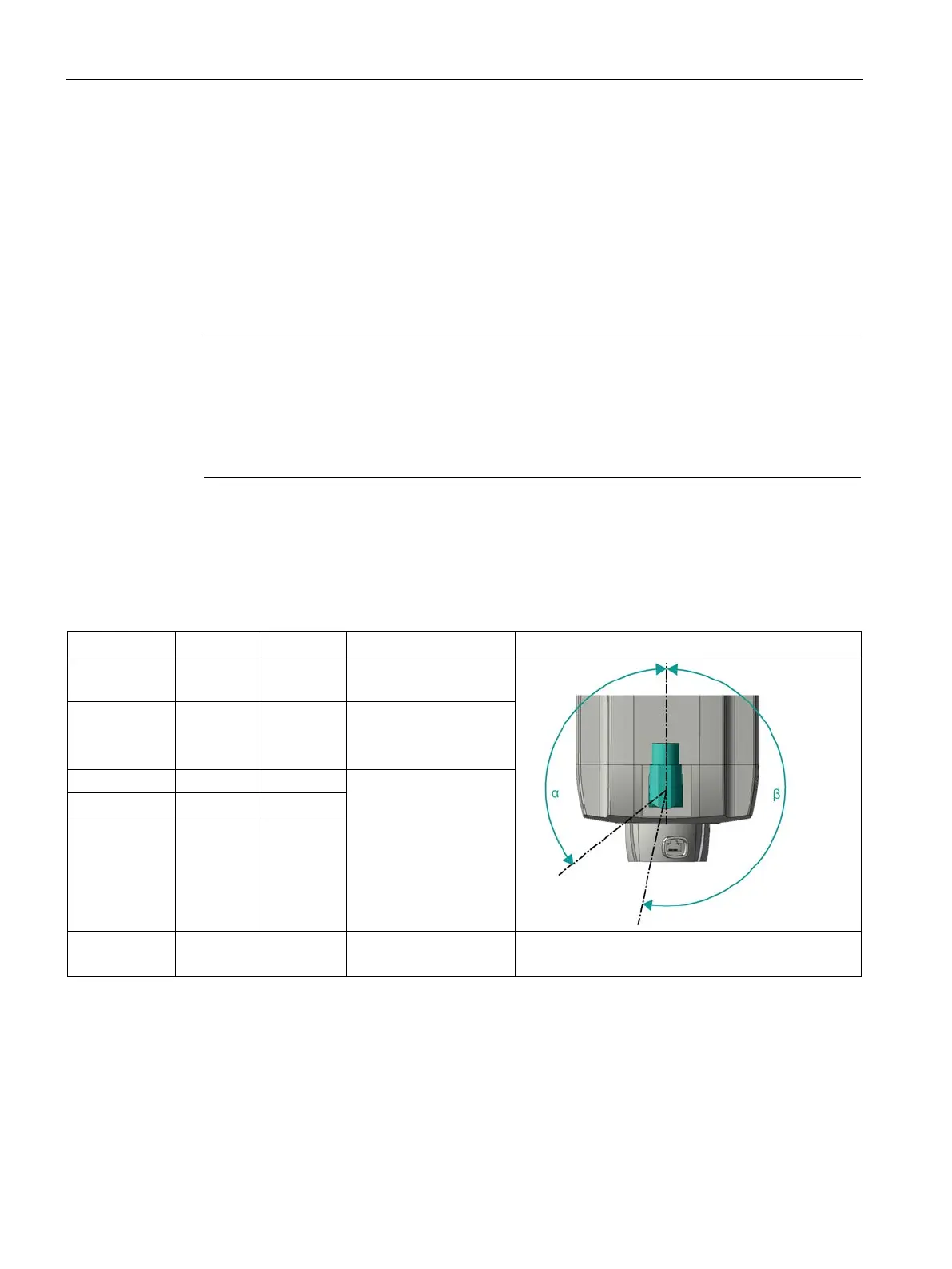

Ability to rotate the power connector on motors with natural cooling / water water cooling and DRIVE-

CLiQ interface 1FT7□□□-□A□□□-□X□□, 1FT7□□□-□W□□□-□X□□; X = B, C

Table 8- 3 Rotation range of the power connector

1FT703☐

130 ° 130 ° M23

1FT706☐

1FT708☐

130 ° 135 °

M23

M40

1FT710☐

1FT713☐

190 ° 135 °

1FT7117

cannot be rotated M58

① Figure power connector, connector size M23

Loading...

Loading...