Mechanical properties

3.3 Types of construction

S-1FT7 synchronous motors

52 Configuration Manual, 09/2018, A5E45099423B AA

Additional measures to increase tightness when using creep-capable oils

● DRIVE-CLiQ encoder with round connector M17, additional information in Chapter

"Motors with DRIVE-CLiQ interface (Page 389)".

● Z option Q13: Encoder sealing (Page 102)

● Z option Q12: Sealing air (Page 100)

Further additional measures to increase tightness

● Protect the motor against media, e.g. with covers.

● Secure the cables in the vicinity of the motor so that no tensile or bending forces act on

the connectors.

● Avoid moving the connectors.

● Avoid pinching the cables due to inadequate bending radii.

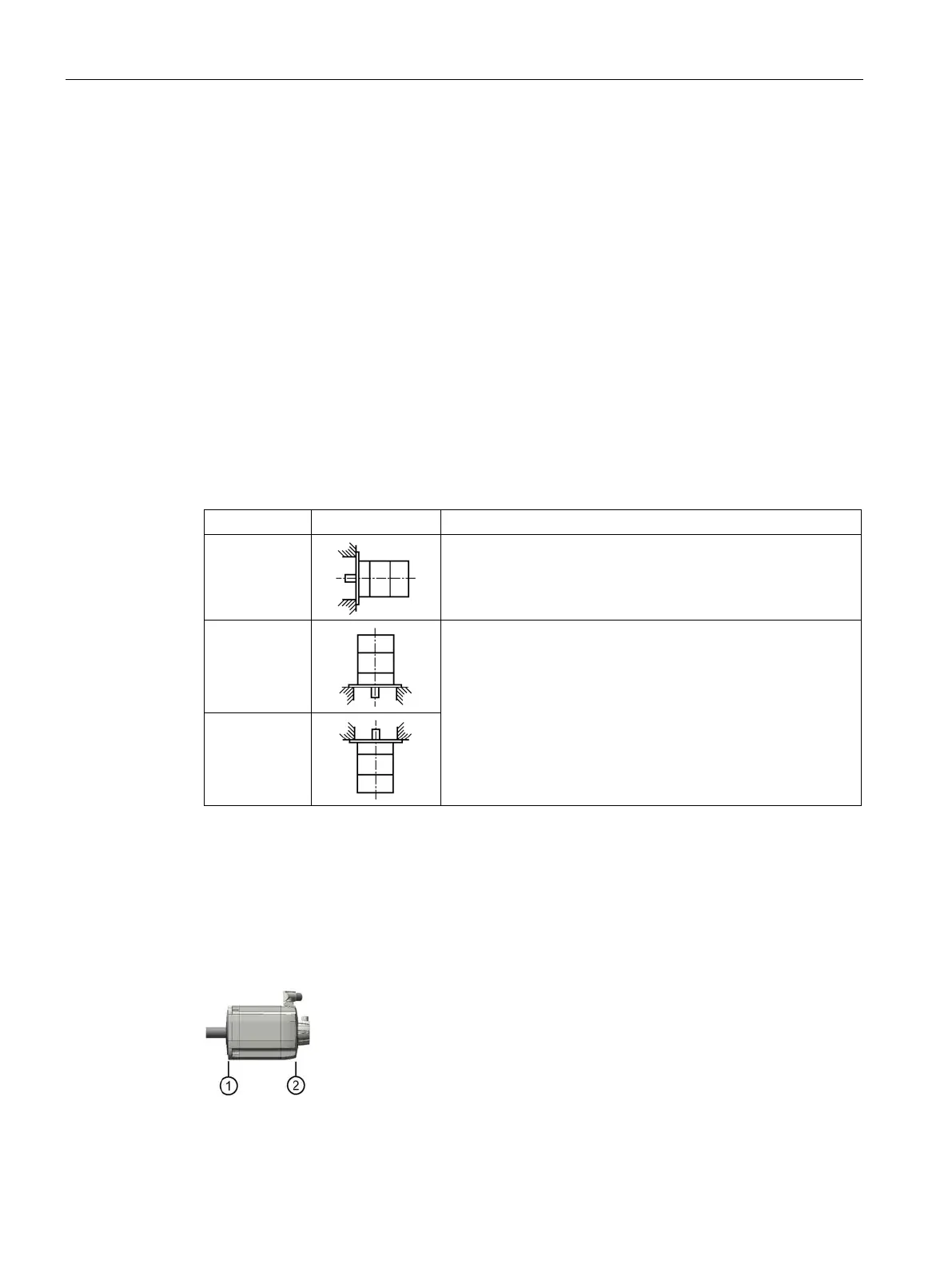

Table 3- 11 Designation of types of construction (acc. to IEC 60034-7)

IM B5

Standard

IM V1

The motors can be used in types of construction

IM V1 and IM V3 without having to order anything special.

Note:

When configuring the IM V3 type of construction, attention must

be paid to the permissible axial forces (force due to the weight

of the drive elements) and especially to the necessary degree of

protection.

IM V3

The motors have rolling bearings with permanent grease lubrication (greased for a lifetime).

The bearing arrangement is a typical fixed-floating design with the fixed bearing at the DE.

The bearing arrangement is for the load case " Circumferential load at the inner ring, point-

type load at the outer ring".

Loading...

Loading...