Mechanical properties

3.1 Cooling

S-1FT7 synchronous motors

44 Configuration Manual, 09/2018, A5E45099423B AA

Pressure conditions in the cooling circuit

Consider the following pressure conditions when designing the cooling circuit.

● Define the working pressure based on the flow conditions in the supply and return pipes

of the cooling circuit.

The maximum permitted pressure in the cooling circuit is 0.6 MPa (6 bar).

Note

If you use a pump that reaches a higher pressure, maintain a maximum pressure of 0.6

MPa

by taking appropriate measures (pressure relief valve, pre

ssure control, etc.).

● Design the cooling circuit to have the smallest possible pressure difference between the

supply and return pipes so that pumps with a shallow characteristic curve can be used.

● Design the cooling circuit with a self-cleaning filter to avoid blockage and corrosion.

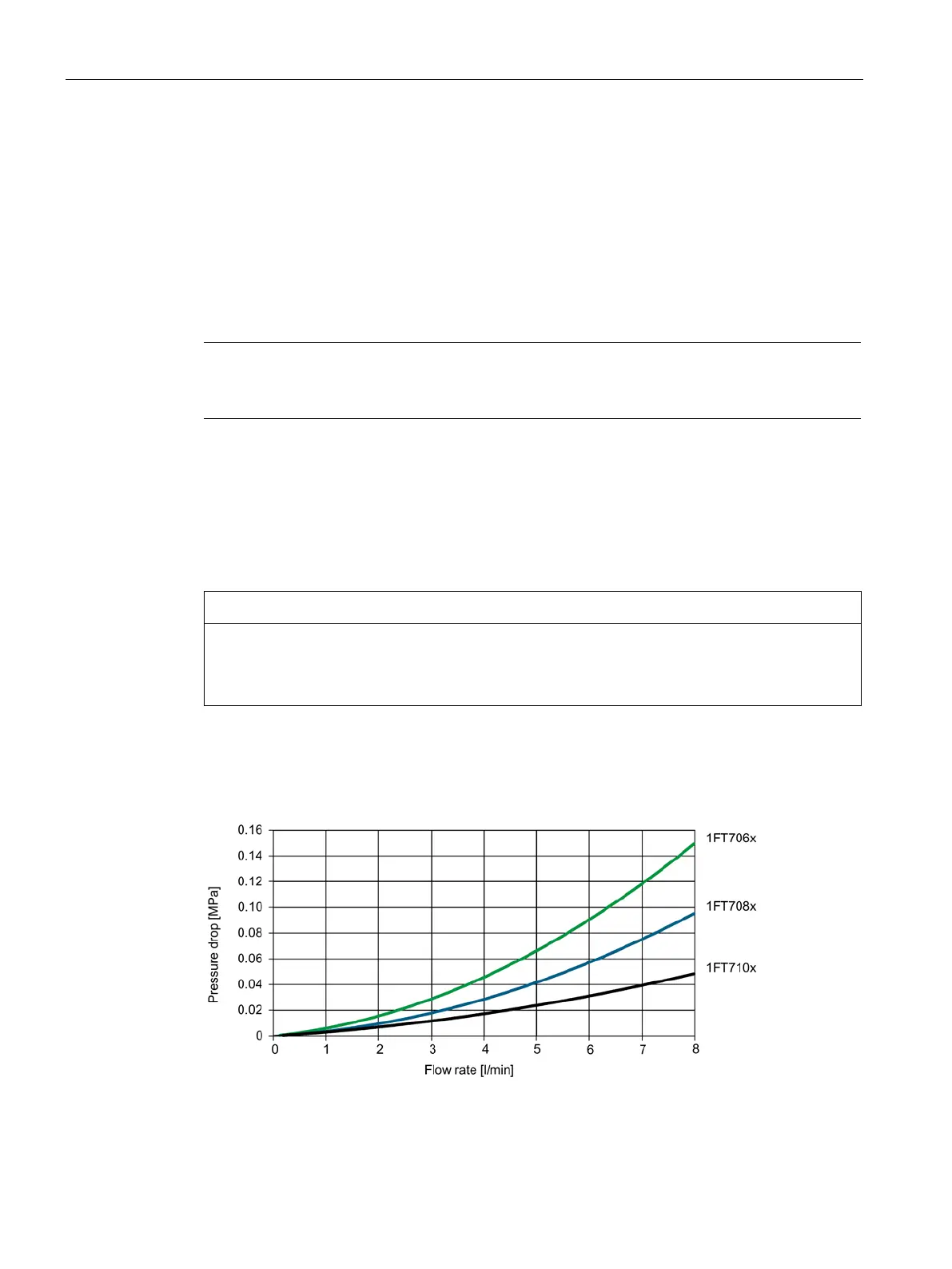

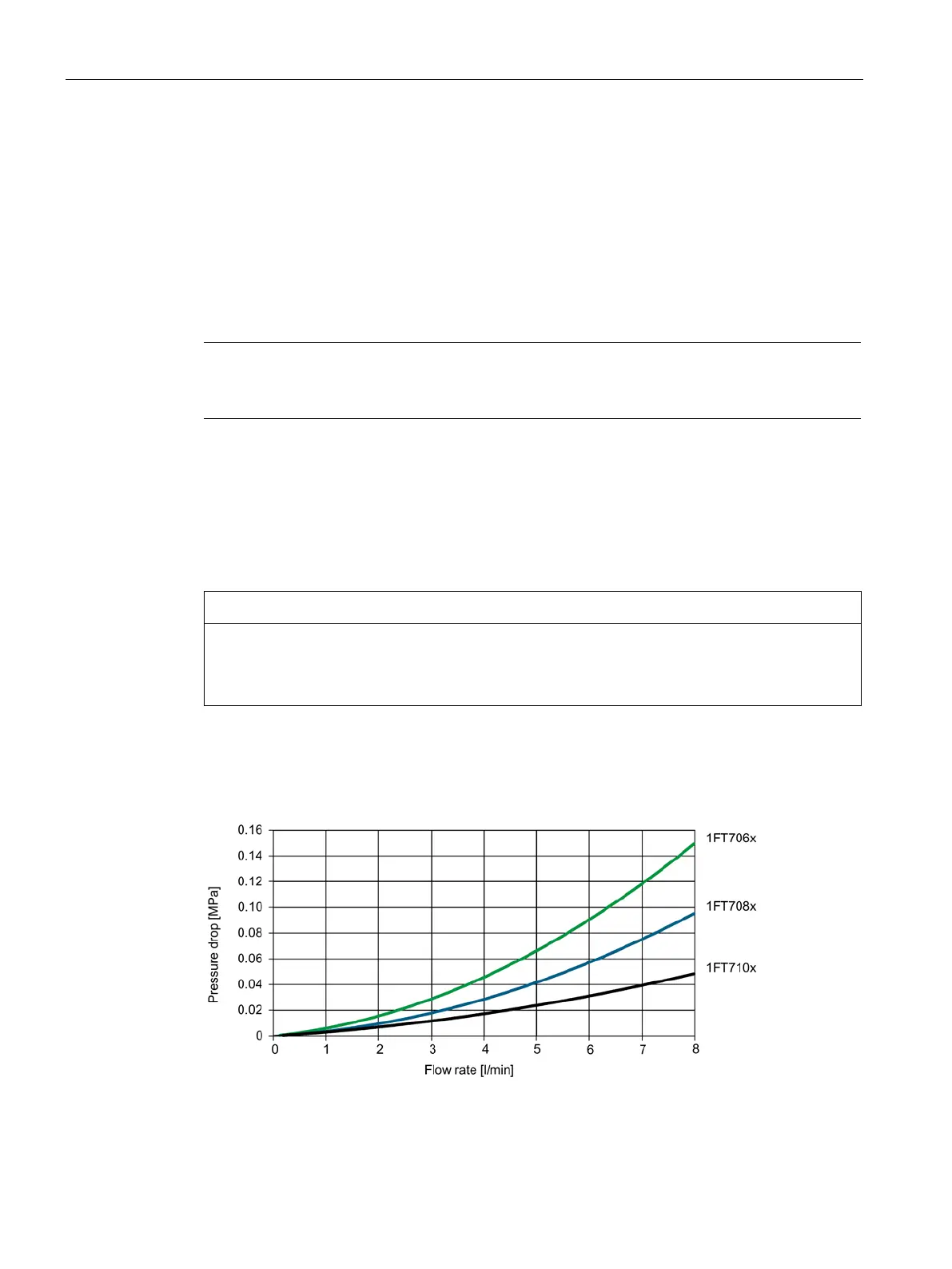

Pressure drop in the motor

Motor damage caused by cavitation and abrasion

An excessive pressure drop causes cavitation or abrasion damage.

• Do not exceed the maximum permissible pressure drop.

During continuous operation, the maximum permissible pressure drop across a motor can be

0.2 MPa (2 bar).

The pressure drops for 1FT7 motors are shown in the diagram below.

Figure 3-3 Pressure drop 1FT7

Loading...

Loading...