Operation

8.6 faults

1LA5/6/7/9, 1LG4/6, 1MA6/7, 1MB..1/2/3/4/5 - SH 63 ... 355

108 Operating Instructions, 06/2018, A5E44455710A

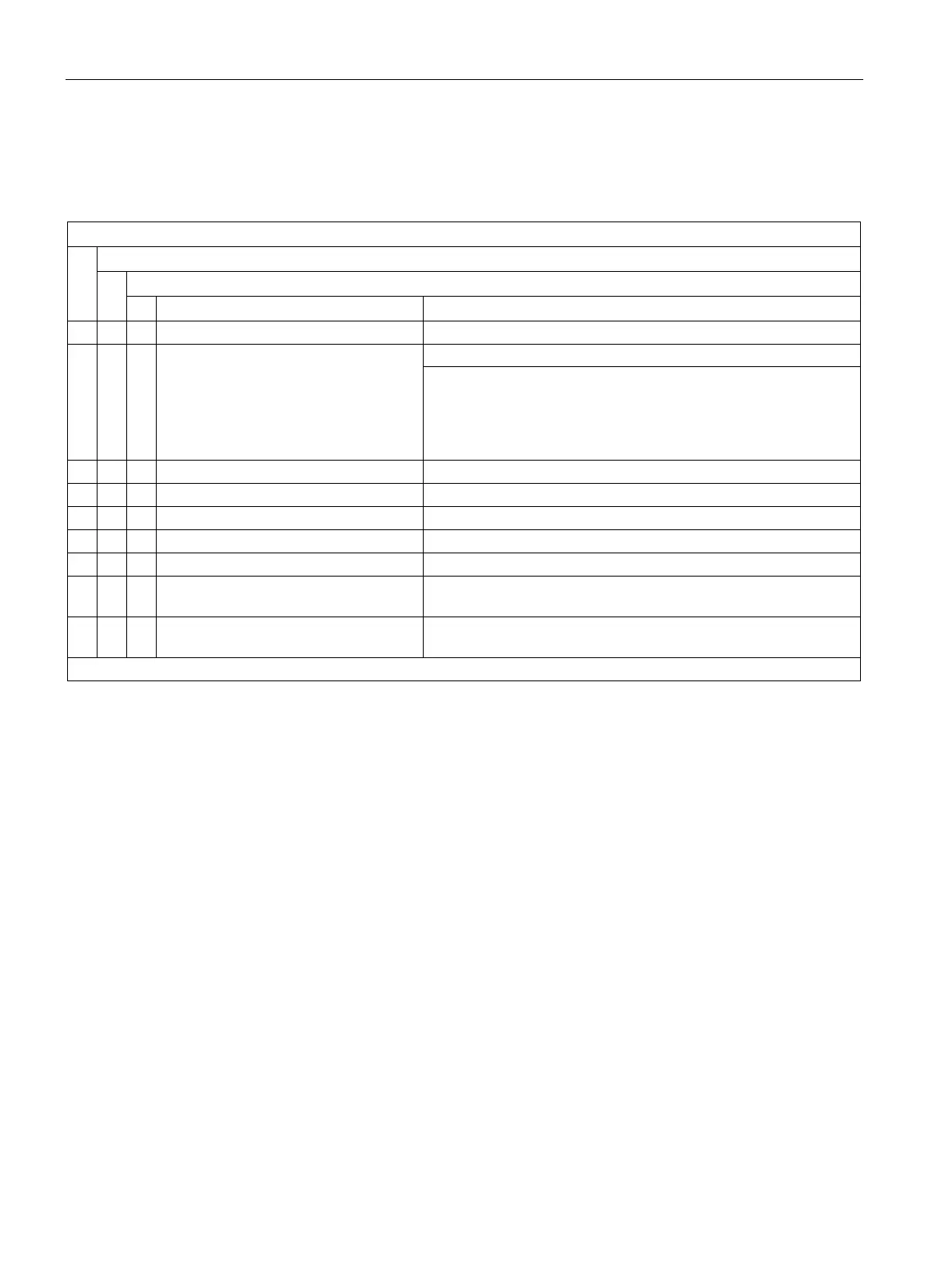

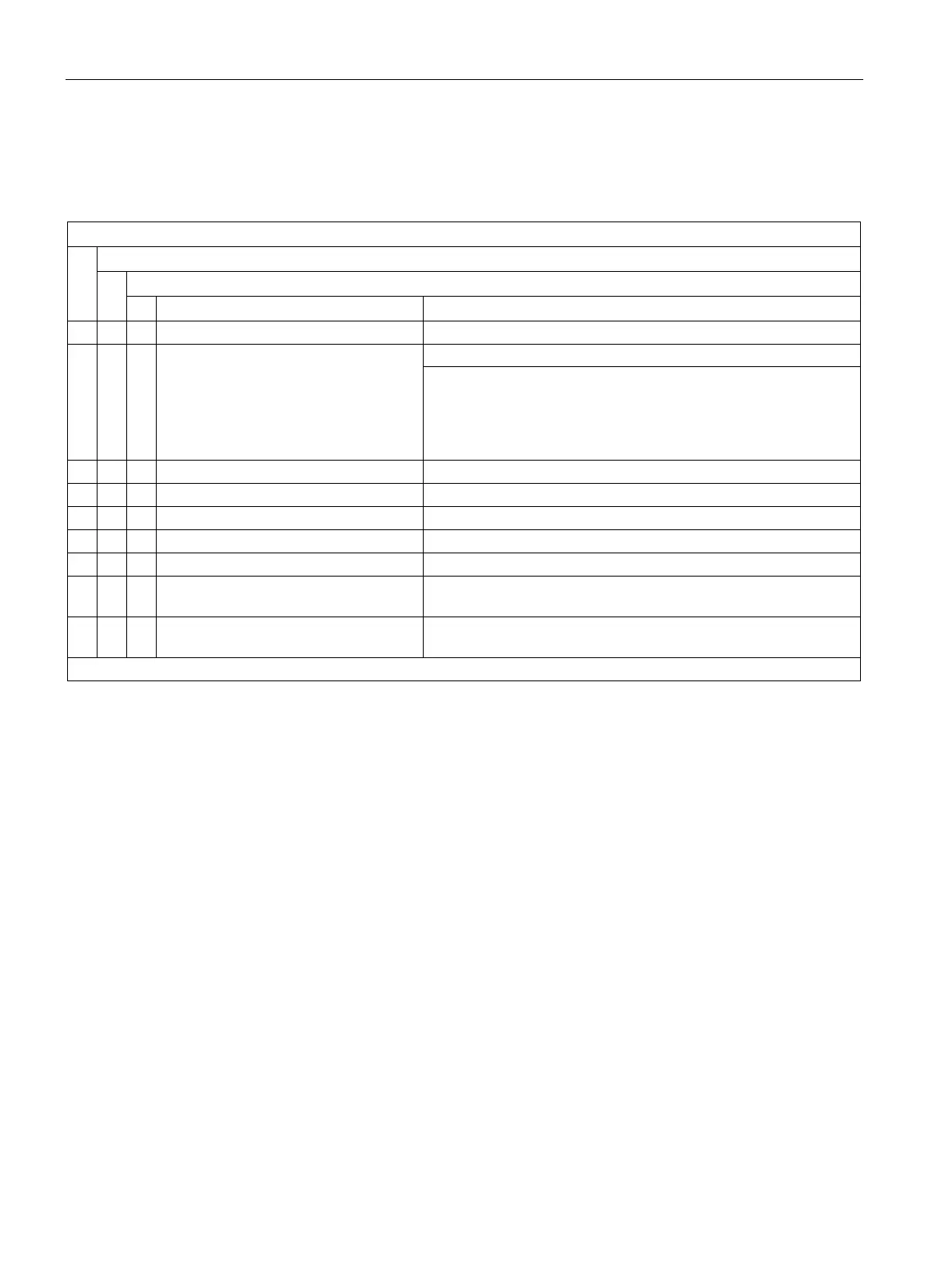

Table 8- 2 Mechanical faults

Possible causes of faults

X Rotating parts grind Establish the cause and realign the parts.

X Stator or coupling not balanced.

Disconnect the stator or coupling and rebalance.

If the machine has two shaft ends, and a transmission element is

only fitted to one end, secure the fitted key at the other end to

prevent it from being thrown out. If the rotor has balance type "H"

(standard type), the fitted key must be cut back to roughly half of

Rotor out of true, shaft bent

Consult the manufacturing plant.

Align the machine set; check the coupling.

(1)

Coupled machine not balanced

Rebalance the coupled machine.

Shocks from coupled machine

Investigate the coupled machine.

Uneven running of gear unit

X X Resonance of the overall system com-

prising motor and foundation

Stabilize the foundation following consultation.

X X Changes in foundation Establish the cause of the changes and eliminate them if neces-

sary; realign the machine.

(1)

Take any changes into account when warming up the machine.

Loading...

Loading...