Operation

8.7 Deactivating

1LA5/6/7/9, 1LG4/6, 1MA6/7, 1MB..1/2/3/4/5 - SH 63 ... 355

Operating Instructions, 06/2018, A5E44455710A

109

Damage to rolling bearings can be difficult to detect in some cases. If in doubt, replace the

rolling bearing. Use other bearing designs only

after consulting the manufacturer

.

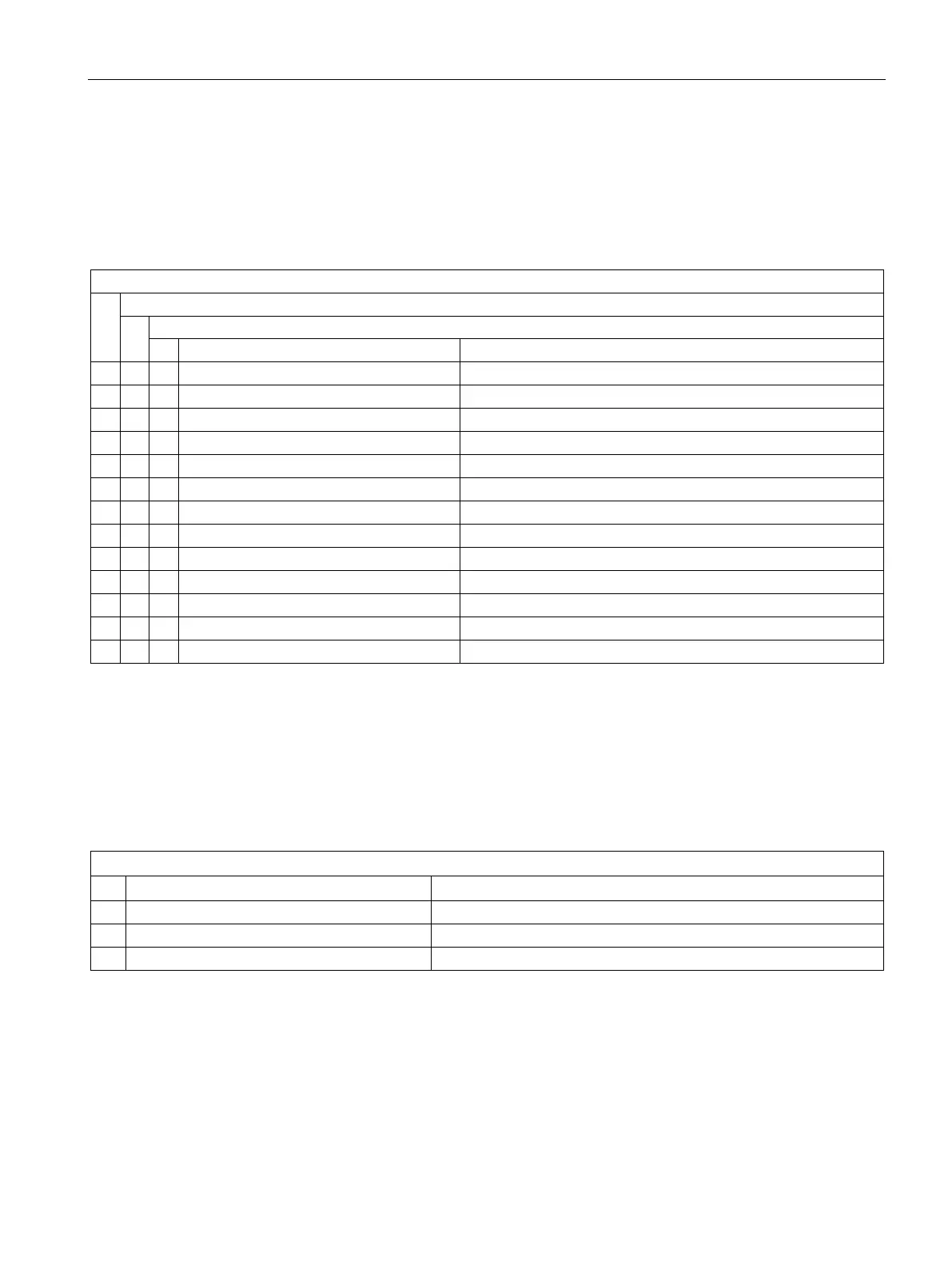

Table 8- 3 Rolling bearing faults

Possible causes of faults

X High coupling pressure Align the machine more accurately.

Reduce the drive belt tension.

Clean or replace the bearing. Check the seals.

Use a suitable high-temperature grease.

Grease the bearings as instructed.

Contact the service center.

Insufficient bearing play

Contact the service center.

Contact the service center.

Replace the bearing. Check the seals.

Too much grease in bearing

Wrong grease in the bearing

Friction marks on raceway

Replace the bearing. Avoid any vibration at standstill

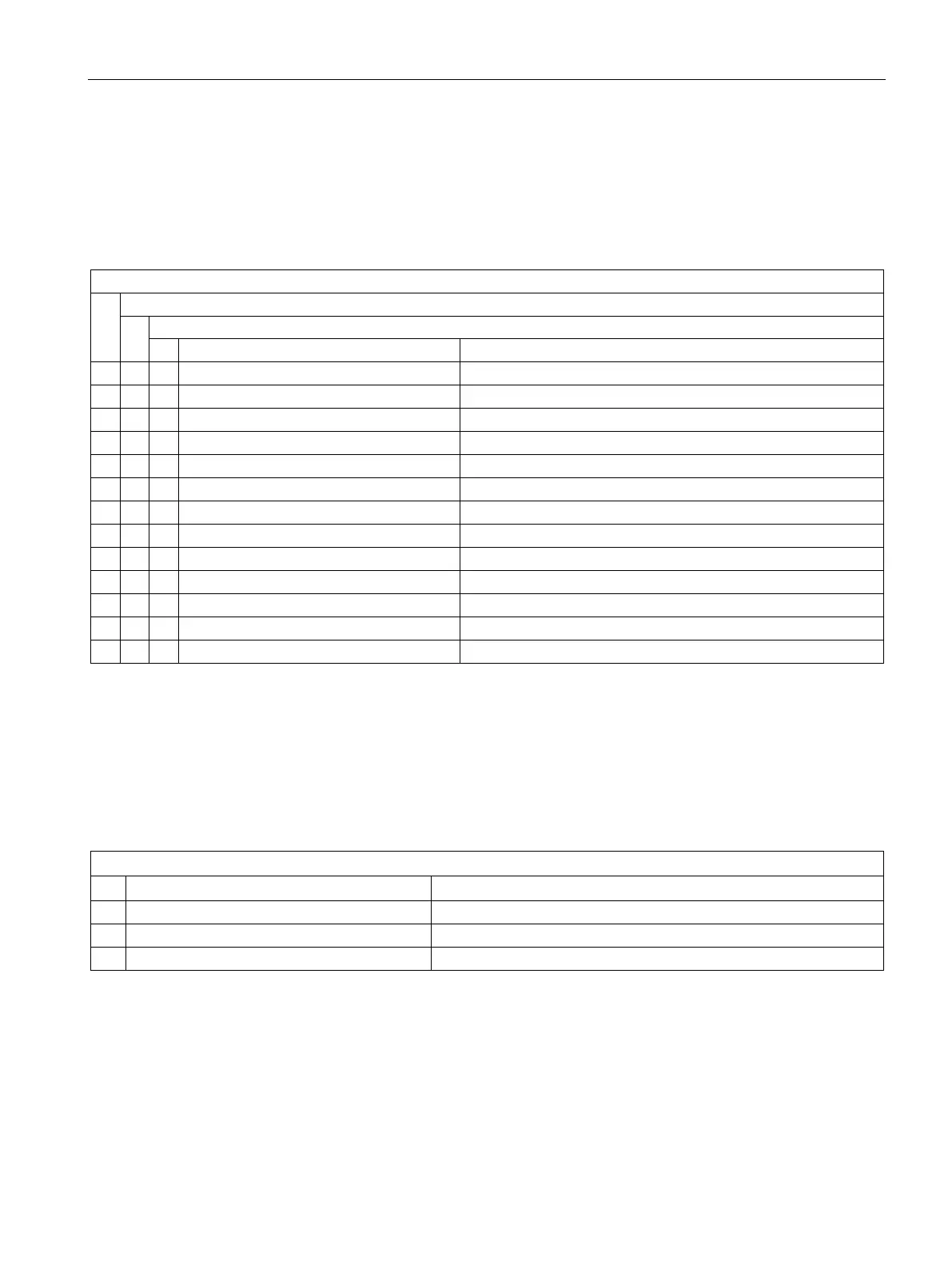

Faults at the external fan

The following table shows the possible causes of and remedial measures for faults on

forced-ventilated machines.

Table 8- 4 Cooling system faults

↓ High temperature rise with load

Possible causes of faults

Wrong direction of rotation of the external fan

Check the electrical connections to the external fan.

External fan is not running

Check the external fan and its connections.

Check the air ducts; clean the machine.

Commission any devices provided for protection against condensation after switching off the

machine.

Loading...

Loading...