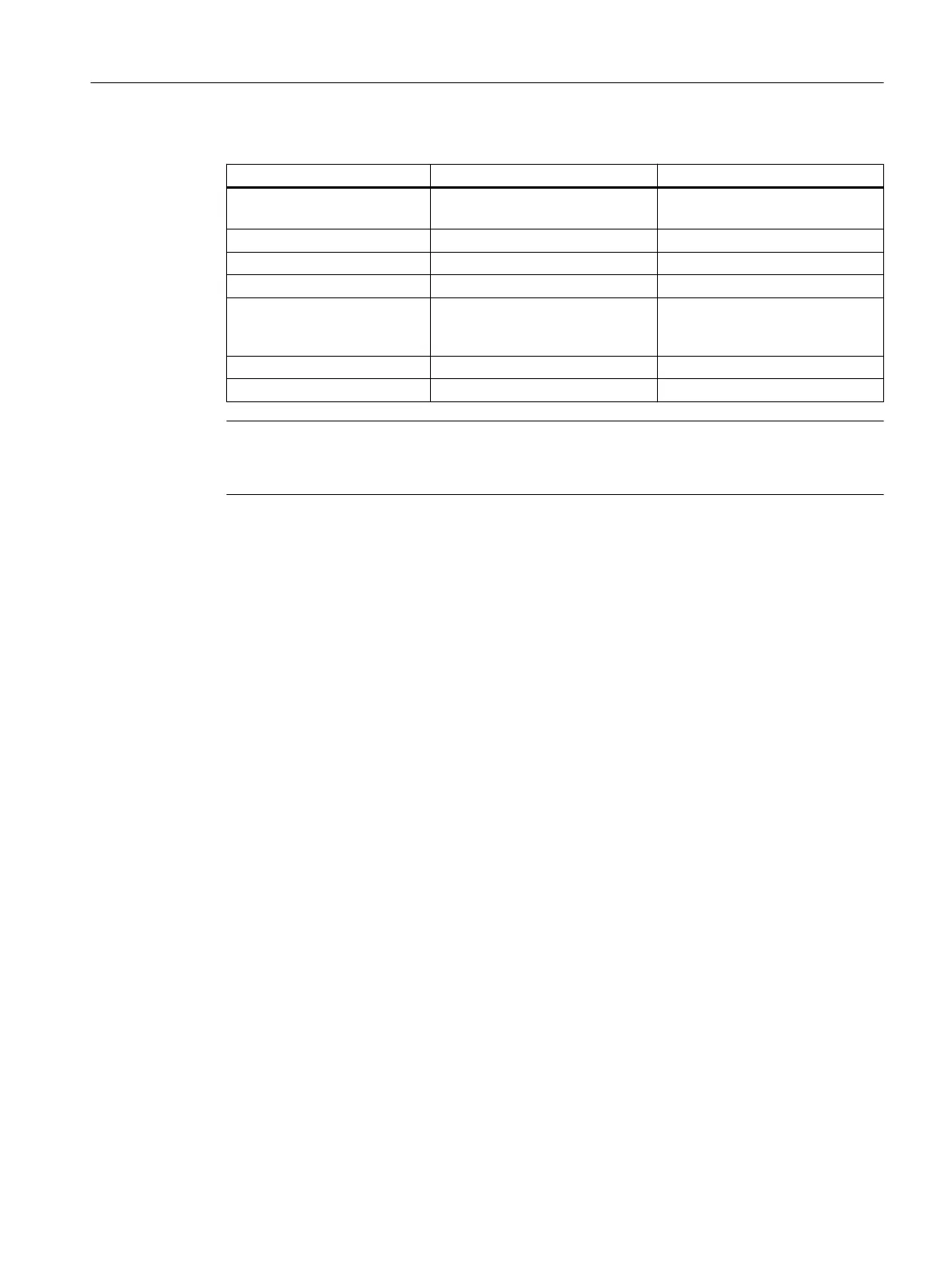

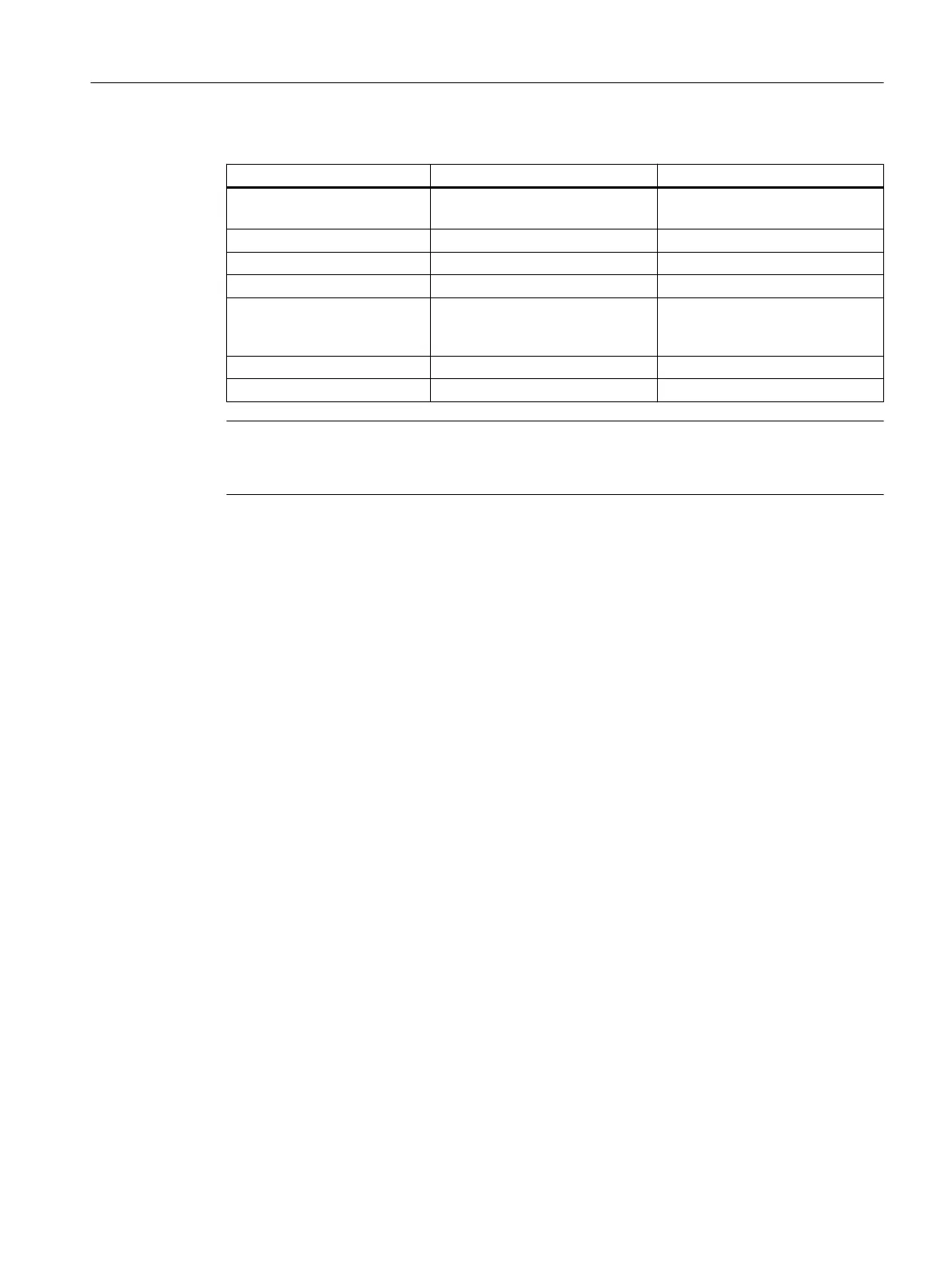

Table A-3 Properties of IF1 and IF2

IF1 IF2

PROFIdrive and SIEMENS

telegram

x ‑

Free telegram x x

Isochronous mode x x

Drive object types All All

Can be used for PROFINET IO, PROFIBUS DP,

SINAMICS Link, PN Gate, Ether‐

net/IP

PROFINET IO, PROFIBUS DP,

CANopen, SINAMICS Link,

PN Gate, Ethernet/IP

Cyclic operation x x

PROFIsafe x x

Note

For additional information on the IF1 and IF2 interfaces, see chapter "Parallel operation of

communication interfaces (Page 90)" in this manual.

Connecting a PG/PC with the STARTER/Startdrive commissioning tool

The following connection options are available for commissioning a Control Unit with a PG/PC

using the commissioning tool.

● STARTER: PROFIBUS, PROFINET, or Ethernet.

● Startdrive: PROFINET or Ethernet.

A.1.1.1 PROFIdrive application classes

According to the scope and type of application processes, PROFIdrive is divided into a total

of 6 application classes, of which the 3 important classes are compared below:

● Class 1 (AK1):

The drive is controlled via a speed setpoint by means of PROFIBUS/PROFINET. Speed

control is fully handled in the drive.

Typical application examples include simple frequency converters for controlling pumps

and fans.

● Class 3 (AK3):

In addition to the speed control, the drive also includes a closed-loop position control.

● Class 4 (AK4):

This application class defines a speed setpoint interface, where the speed control is realized

in the drive and the closed-loop position control in the control system, such as is required

for robotics and machine tool applications with coordinated motion sequences on multiple

drives.

Motion control is primarily implemented using a central numerical controller (NC).

Communication

A.1 Communication

Industrial Security

Configuration Manual, 08/2017, A5E36912609A 85

Loading...

Loading...