WORKSHOP MANUAL

T...102/122 - TC...102/122

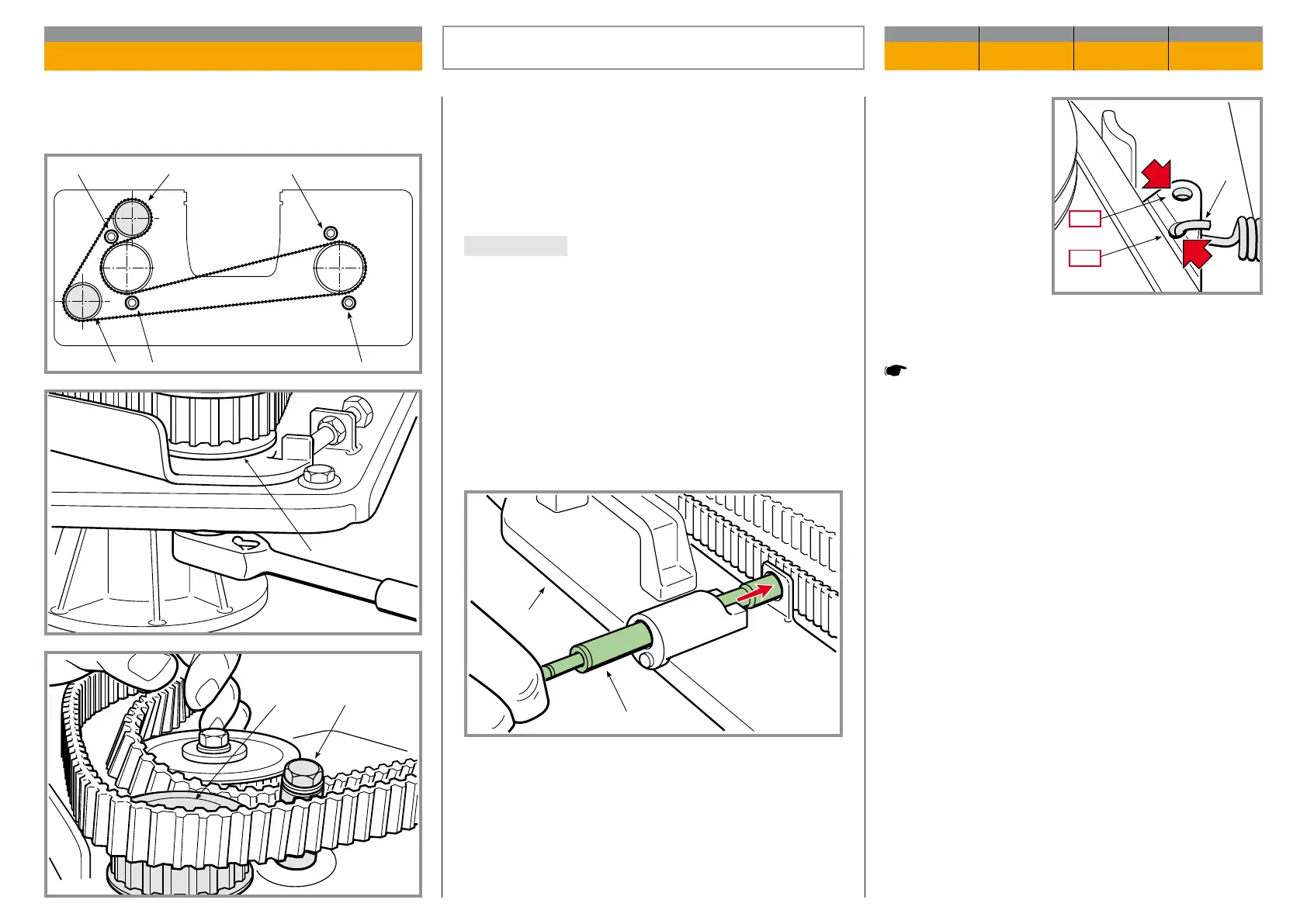

When retting the

spring (2), make sure

that it is con nected to

the hole provided for

each model.

Finally, when reassembly is complete, it is advisable

to …

Check the adjustment of the blades engagement.

Ret everything by reversing the operations de scri-

bed above. Reset the adjuster reading recorded pre-

viously and check that the blades are at 90° to each

other before locking the pin (11) and pulleys (13) and

(14).

IMPORTANT On reassembly, check that the washer

under the pin (11) is not damaged and that the outer

pin rol lers run freely.

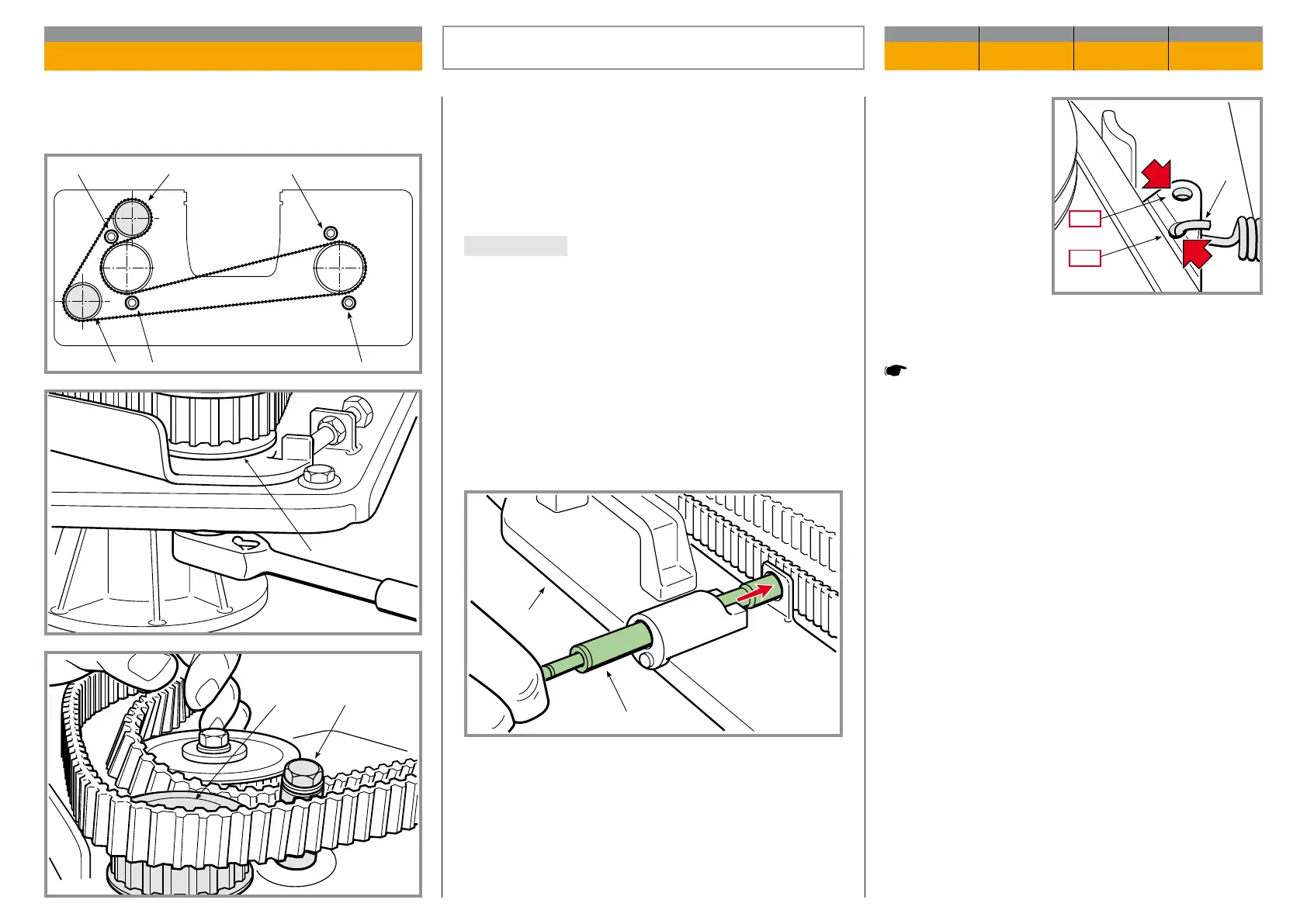

Use the specic tool (15) to check the piston (16) for

the belt give values and the force applied, and use the

stretcher until a give of 9 ÷ 10 mm is ob tai ned, exert-

ing a force of:

– 3,5 kg mod. 102

– 4,2 kg mod. 122

Reassemble the casing, stretcher and blades control

belt, taking care over their exact positioning with re-

spect to the pins and containment guides.

Fit the new belt so that, when the two long sections

are held taut, the two blades are at 90° to each other.

REPLACEMENT OF THE

BLADES CONNECTION BELT

CHAPTER REVISION FROM ... PAGE

6.7 0 2018 2 of 2

Loading...

Loading...