WORKSHOP MANUAL

T...102/122 - TC...102/122

Map of functional units

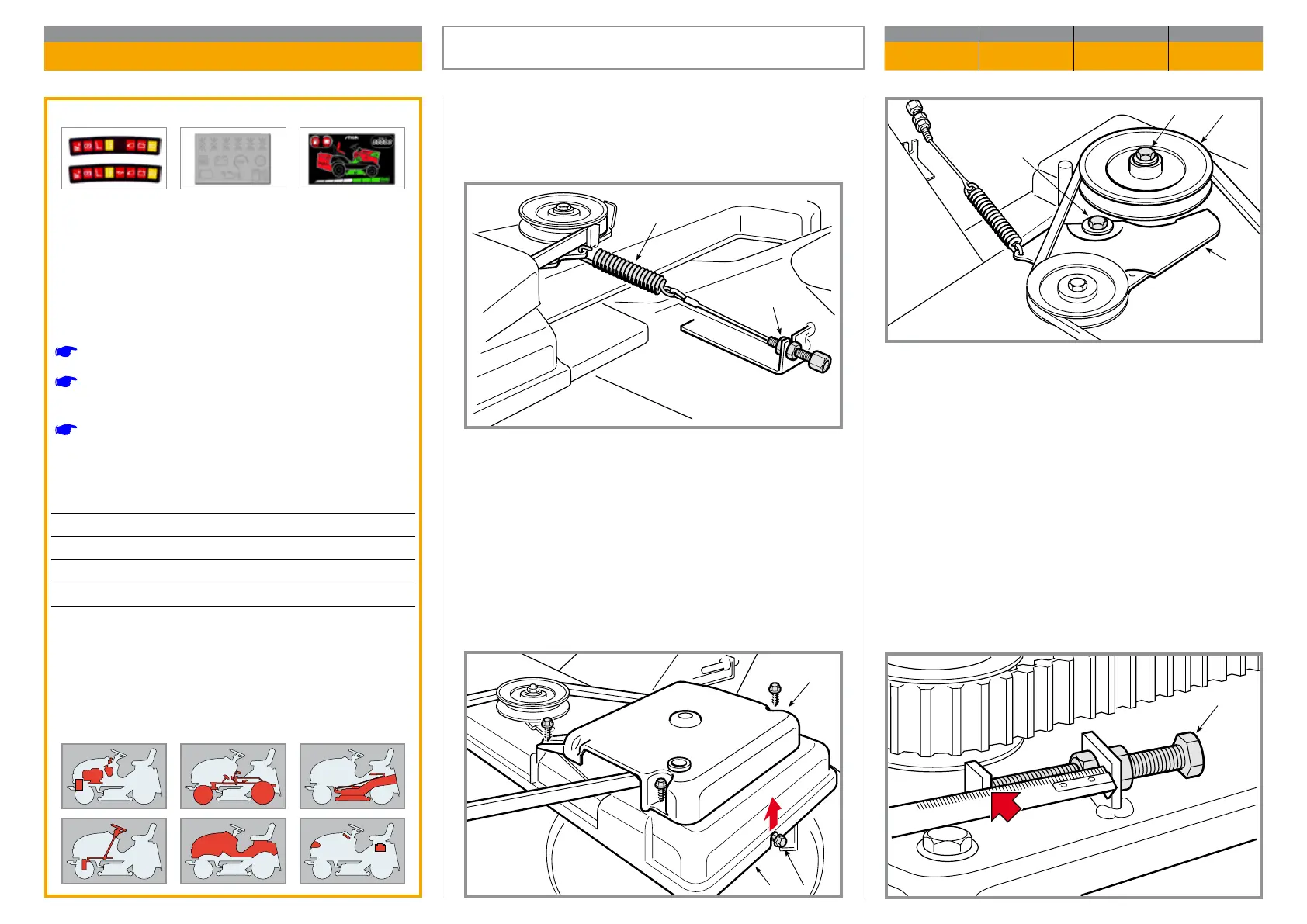

Record the reading on the adjuster (10) (this must

be reset at reassembly to give a preliminary belt ad-

justment) and slacken it o completely.

Dismantle the pin (11), slacken o the xing nuts of

the three pins (12) and the pulleys (13) and (14) to al-

low removal of the belt.

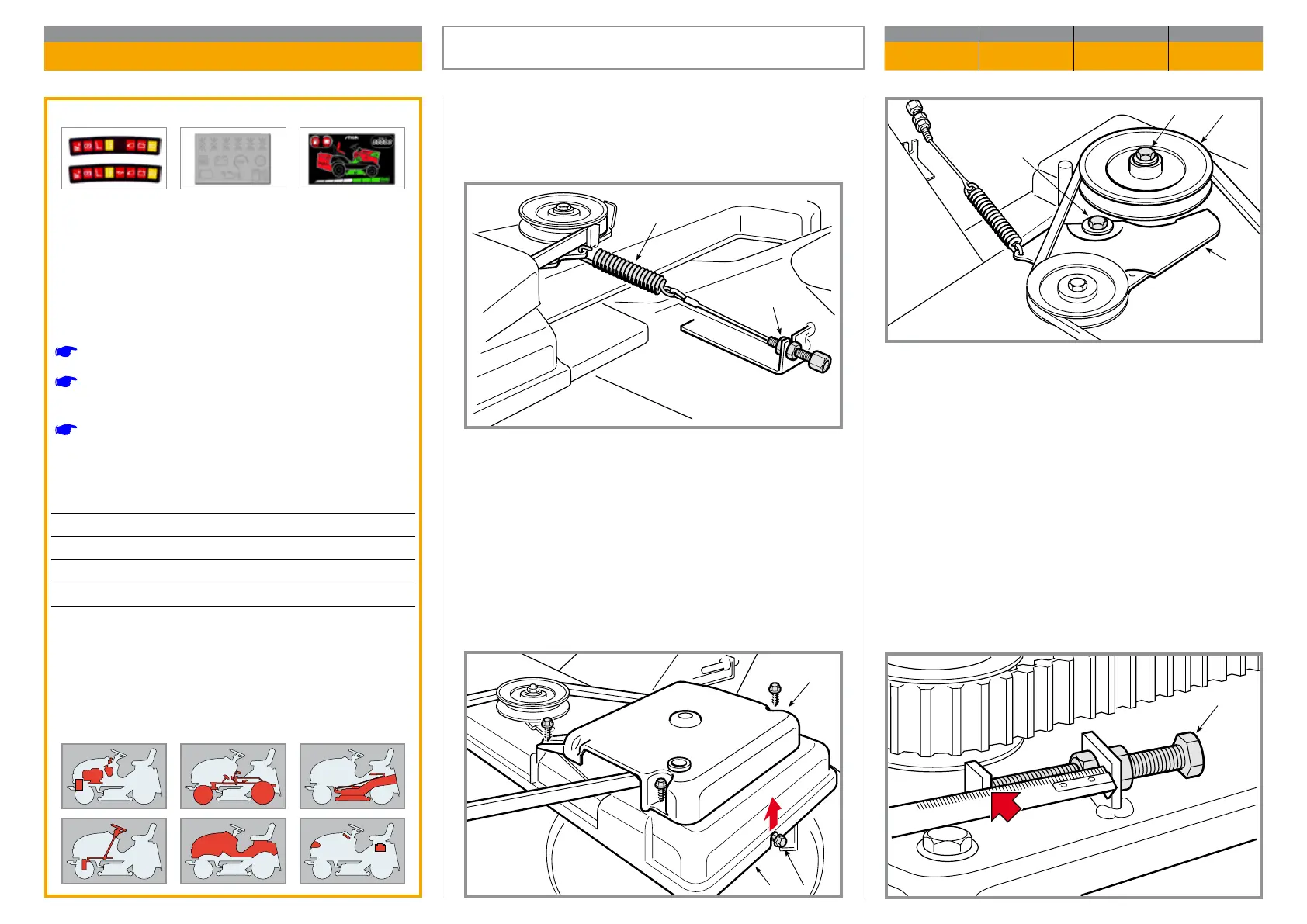

Set the cutting deck to the lowest position to obtain

greater access, then slacken o and uncouple the ad-

juster (1) to unload the spring (2) .

Dismantle the upper casing (3), undo screw (4) and

di smantle the control pulley (5); undo the articulation

screw (6) and remove the stretcher plate (7).

Remove the protection casing (8), slackening o the

six surround screws (9) and extract it from its slots.

Validity

General informations

Related topics

[

2.2] Special tools

[

4.1] Adjusting the engagement and checking

the blade brake

[

8.2] Belts assembly

Tightening torques

4 Blade pulley screws ....................... 20 ÷ 25 Nm

6 Stretcher plate articulation screw ... 35 ÷ 40 Nm

11-12 Pin xing nuts ......................... 30 ÷ 35 Nm

13-14 Pulley xing nuts ..................... 30 ÷ 35 Nm

REPLACEMENT OF THE

BLADES CONNECTION BELT

CHAPTER REVISION FROM ... PAGE

6.7 0 2018 1 of 2

Loading...

Loading...