31034, 036, 036 QS

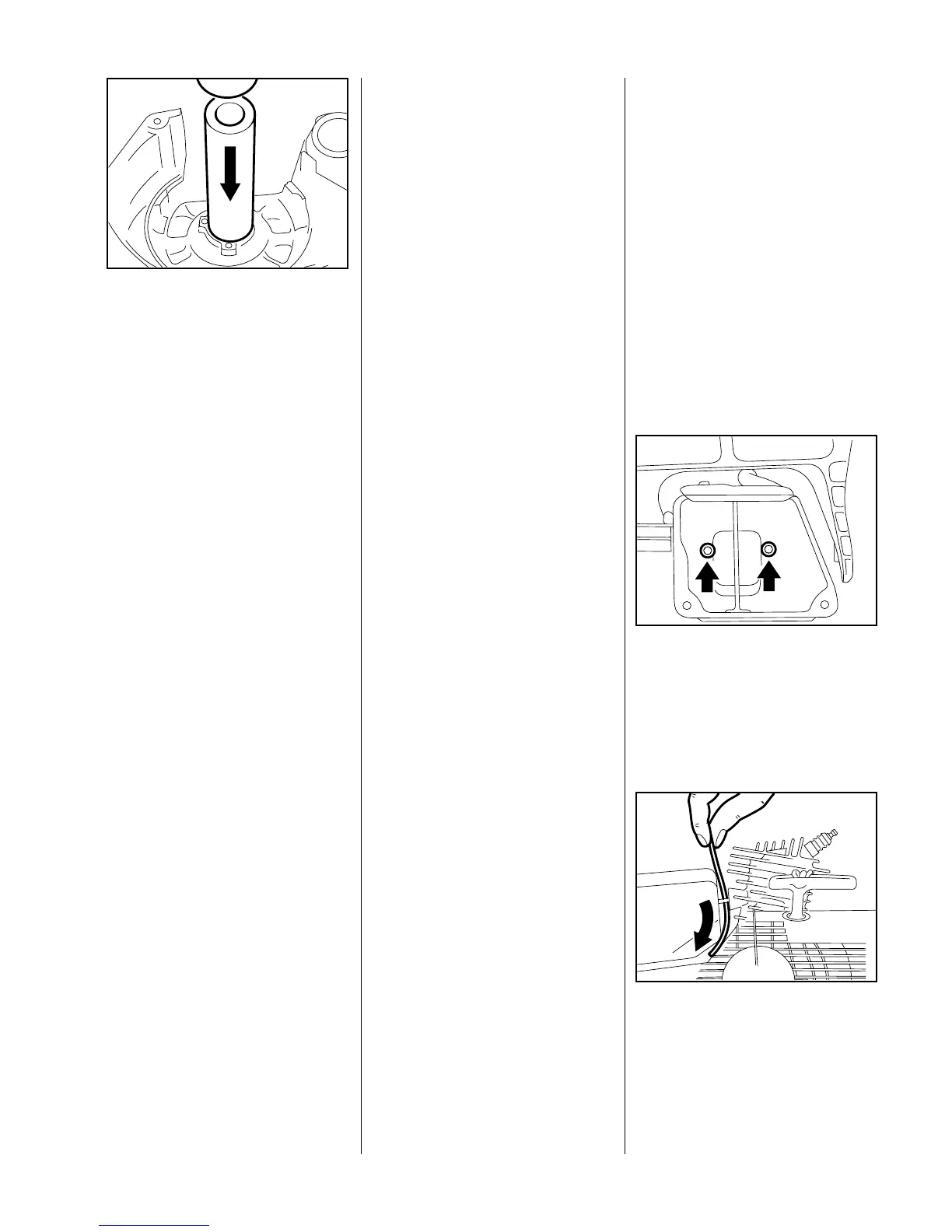

– Slide the oil seal, open side

facing the crankcase, over the

ignition end of the crankshaft.

Use press sleeve 1121 893 2400

to press home oil seal until sleeve

butts against the crankcase.

VA

138RA079

Important:

It is essential to observe the correct

installed depth of the oil seal to

achieve a proper seal. Always use

the press sleeve for this operation.

– Reassemble all other parts in the

reverse sequence.

Defective oil seals and gaskets or

cracks in castings are the usual

causes of leaks. Such faults allow

supplementary air to enter the

engine and thus upset the fuel-air

mixture.

This makes adjustment of the

prescribed idle speed difficult, if not

impossible.

Moreover, the transition from idle

speed to part or full throttle is not

smooth.

The crankcase can be checked

thoroughly for leaks with the

carburetor and crankcase tester

1106 850 2905 and the vacuum

pump 0000 850 3501.

– Remove the shroud from the

cylinder - see 4.3.

– Take out the muffler upper casing

mounting screws and remove the

upper casing - see 5.1.

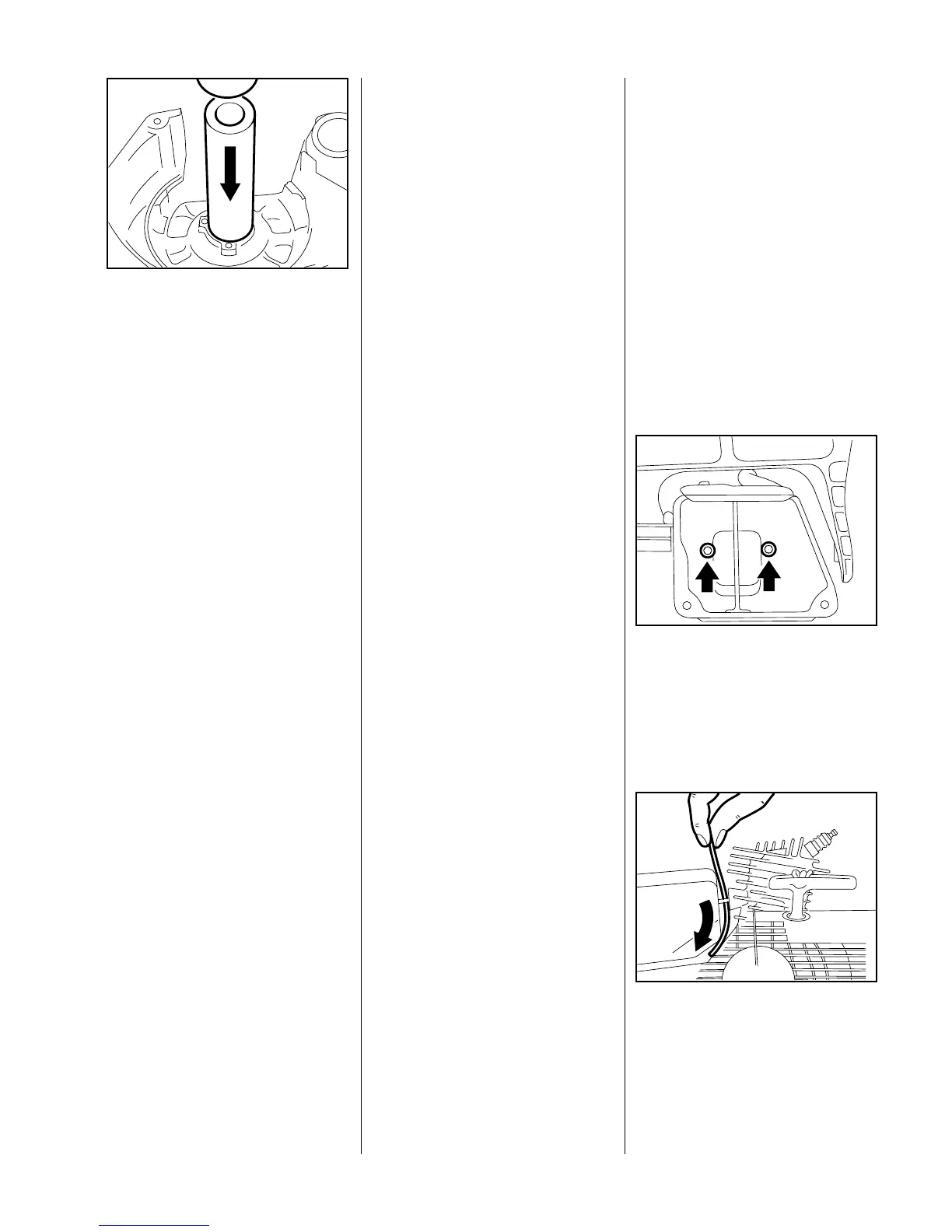

Loosen the muffler lower casing

mounting screws about half way.

VA

138 RA 020

Fit sealing plate 0000 855 8106,

from above and narrow end first,

between the muffler lower casing

and cylinder exhaust port.

Note:

The sealing plate must completely

fill the space between the two

VA

138RA080

5.6 Crankcase Leakage Test 5.6.1 Preparations

Loading...

Loading...