60 034, 036, 036 QS

Installing the prefilter (034, 036):

– Slide the prefilter in the guides in

the carburetor box cover and

make sure its snaps into position.

Installing the main filter:

– Assemble the two halves of the

main filter.

– Fit the filter over the two collar

studs and tighten down the

slotted nuts firmly (see

"Tightening Torques")

– Fit the carburetor box cover, see

also 4.3, and secure by turning

the twist lock one quarter turn to

the right.

Troubleshooting chart - see

"Standard Repairs, Trouble-

shooting" handbook.

Important:

In the case of problems with the

carburetor or fuel supply system,

also check and clean the tank vent

- see 12.6.

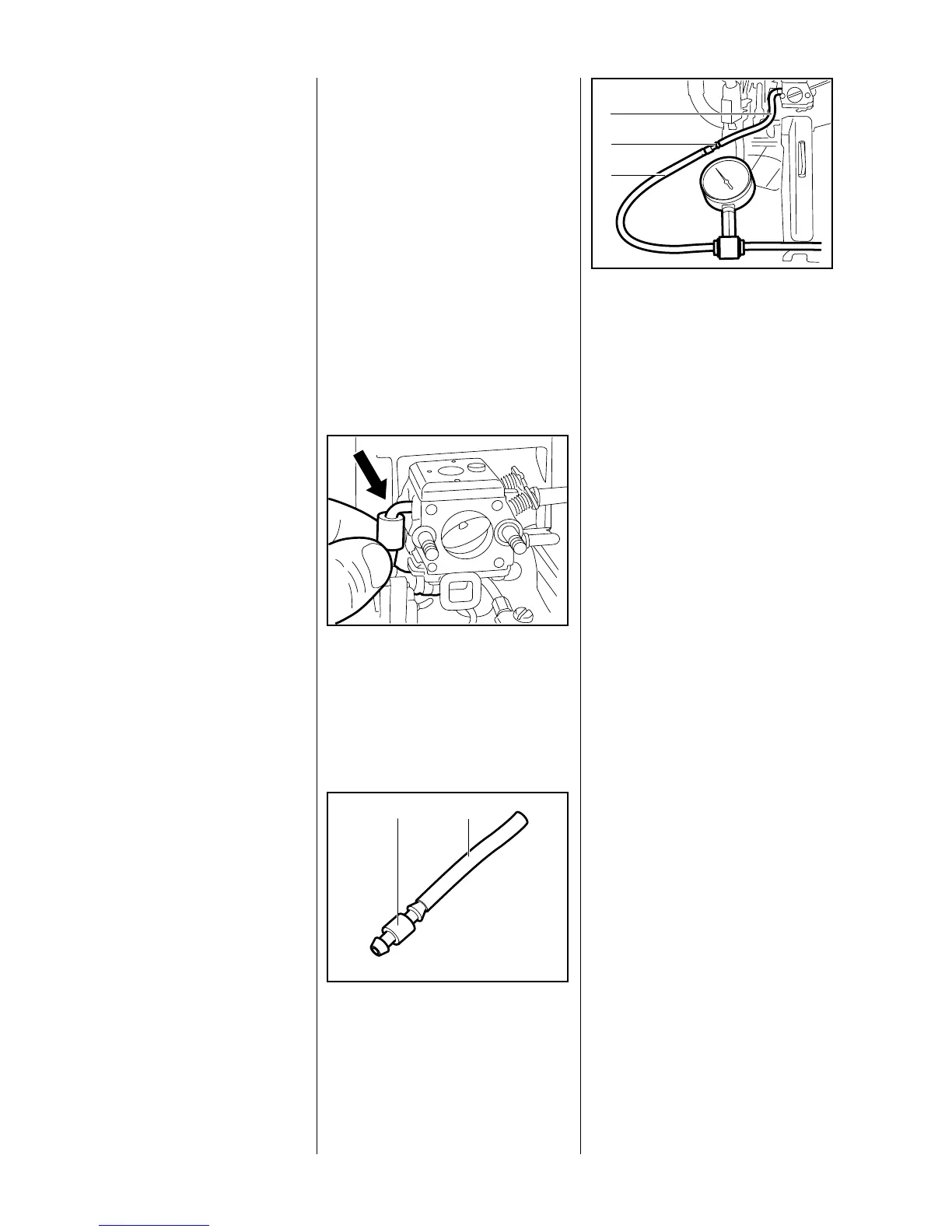

The carburetor can be tested for

leaks with the carburetor and

crankcase tester 1106 850 2905.

– Remove the air filter - see 12.1.

Pull fuel hose off the carburetor’s

elbow connector.

VA

148RA050

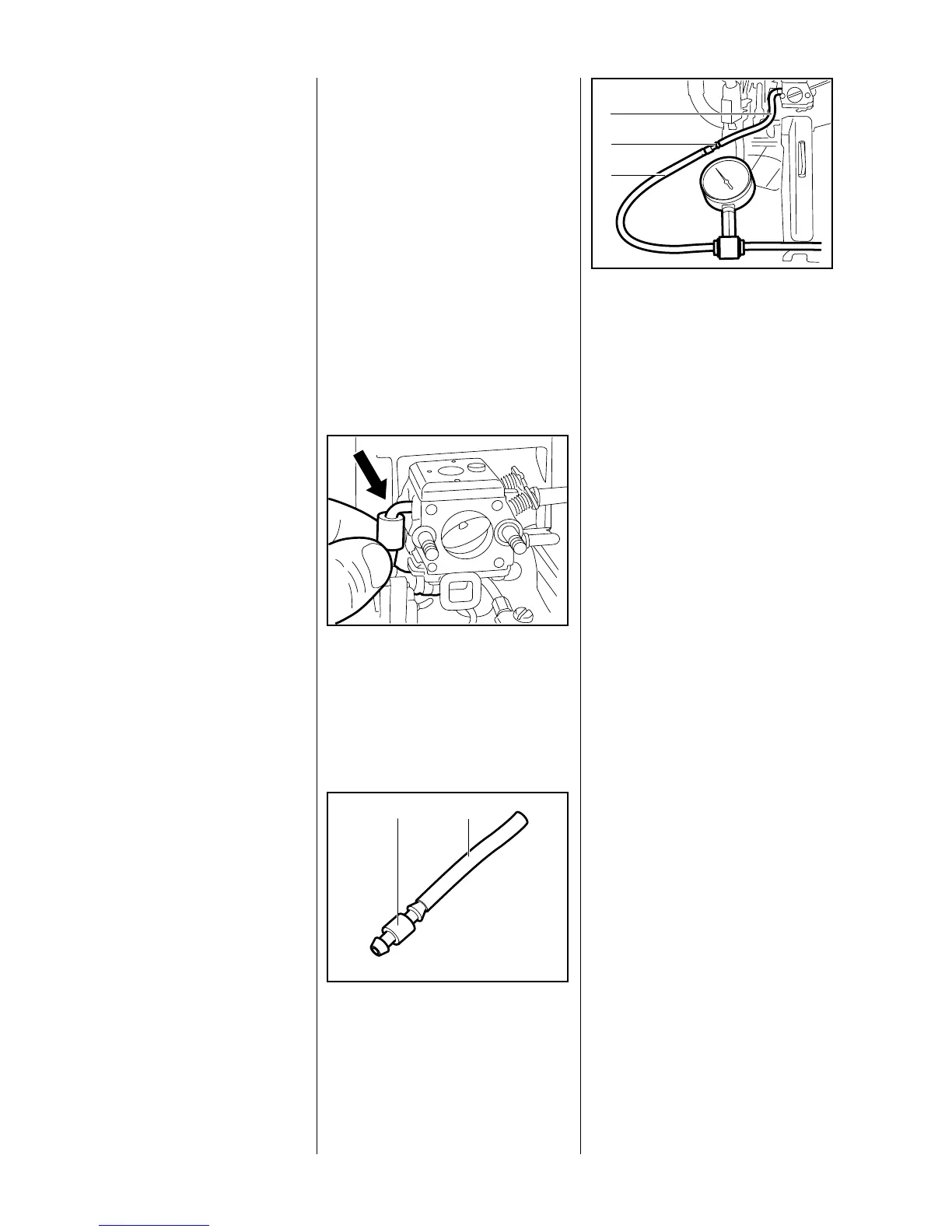

Push fuel hose 1110 141 8600 (1)

onto one end of the nipple

0000 855 9200 (2). Connect

nipple to tester’s pressure hose.

VA

143RA172

2 1

Push fuel hose (1) with nipple (2)

and tester (3) onto carburetor’s

elbow connector.

– Close the vent screw on the

rubber bulb.

– Squeeze rubber bulb to pump air

VA

138RA218

1

2

3

into the carburetor until the

pressure gauge shows a reading

of approx. 0.4 bar.

If this pressure remains constant,

the carburetor is airtight. However, if

it drops, there are two possible

causes:

1. The inlet needle is not sealing

(foreign matter in valve seat or

sealing cone of inlet needle is

damaged (see 12.4) or inlet control

lever sticking).

2. The metering diaphragm is

damaged.

In either of these cases the

carburetor must be serviced.

– After completing the test, open

the vent screw and pull the fuel

hose off the carburetor.

Reassemble in the reverse

sequence.

Repeat the leakage test after

finishing repairs.

12.2 Leakage Testing the Carburetor

Loading...

Loading...